Non-uniformity correction device for infrared camera

A technology of non-uniformity correction and infrared camera, which is applied to cameras, camera bodies, TVs, etc., can solve the problems of reducing the service life of infrared cameras and the inability to use manual methods to achieve camera non-uniformity correction, etc., and achieves simple structure, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the drawings and specific embodiments.

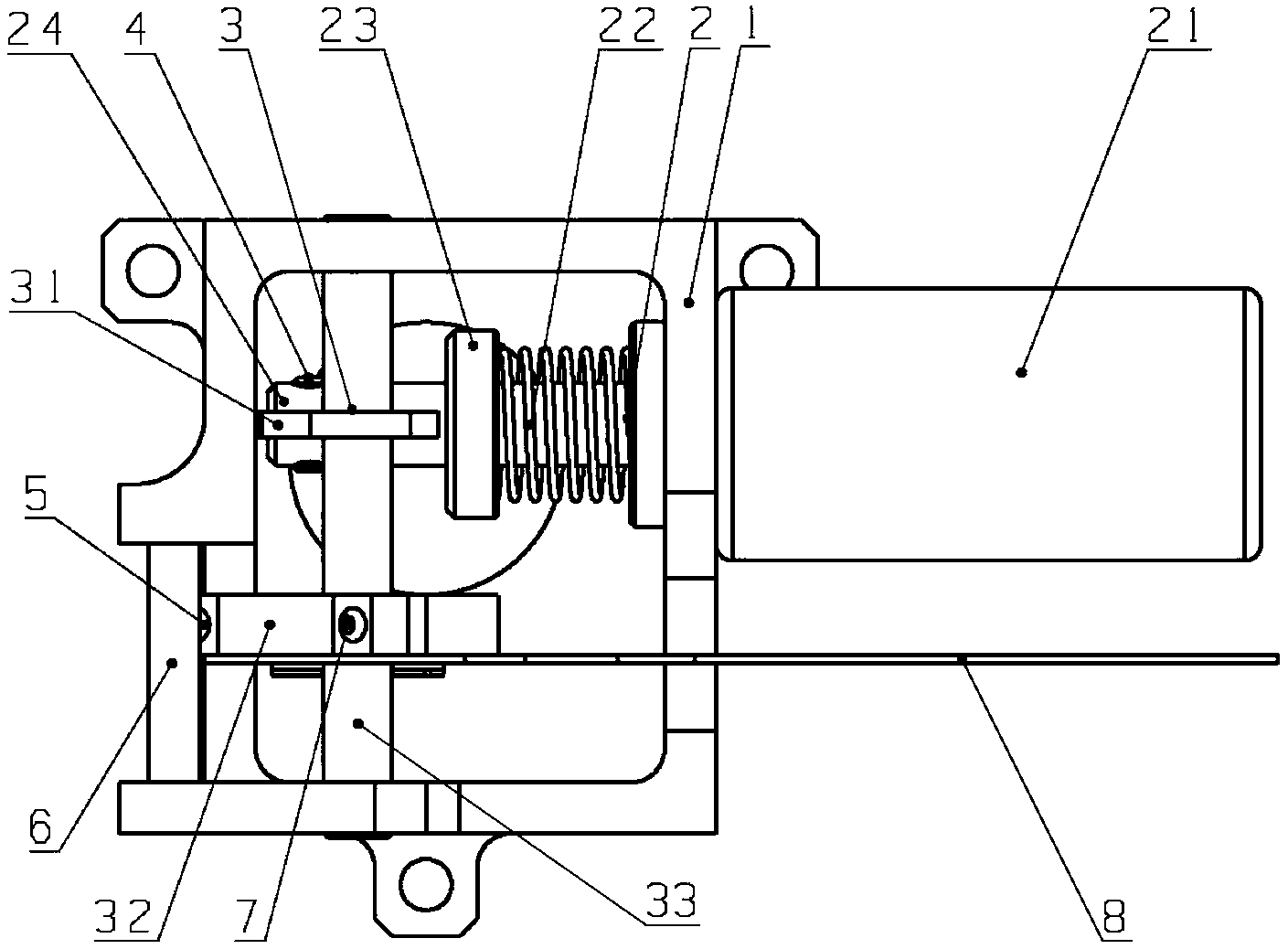

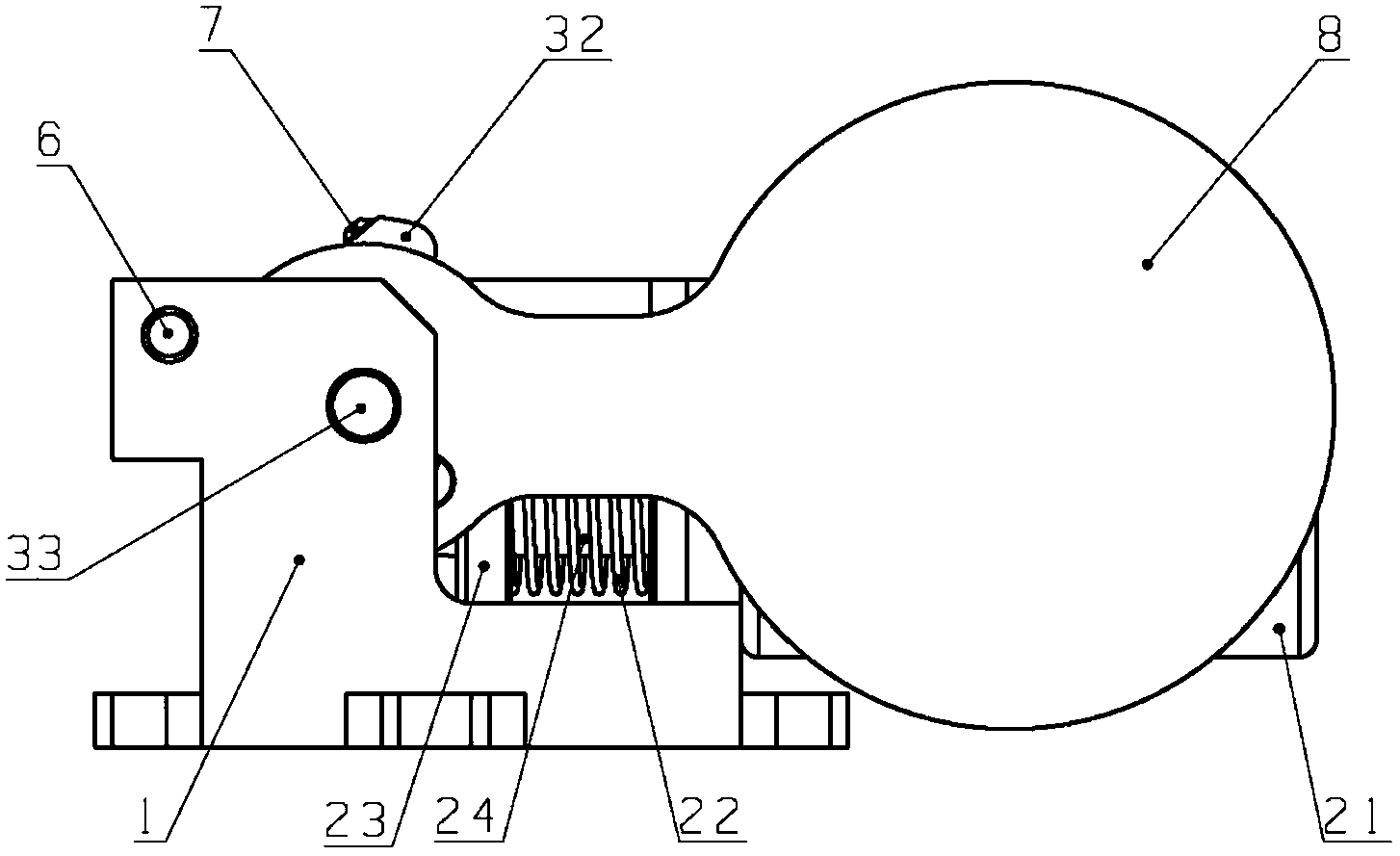

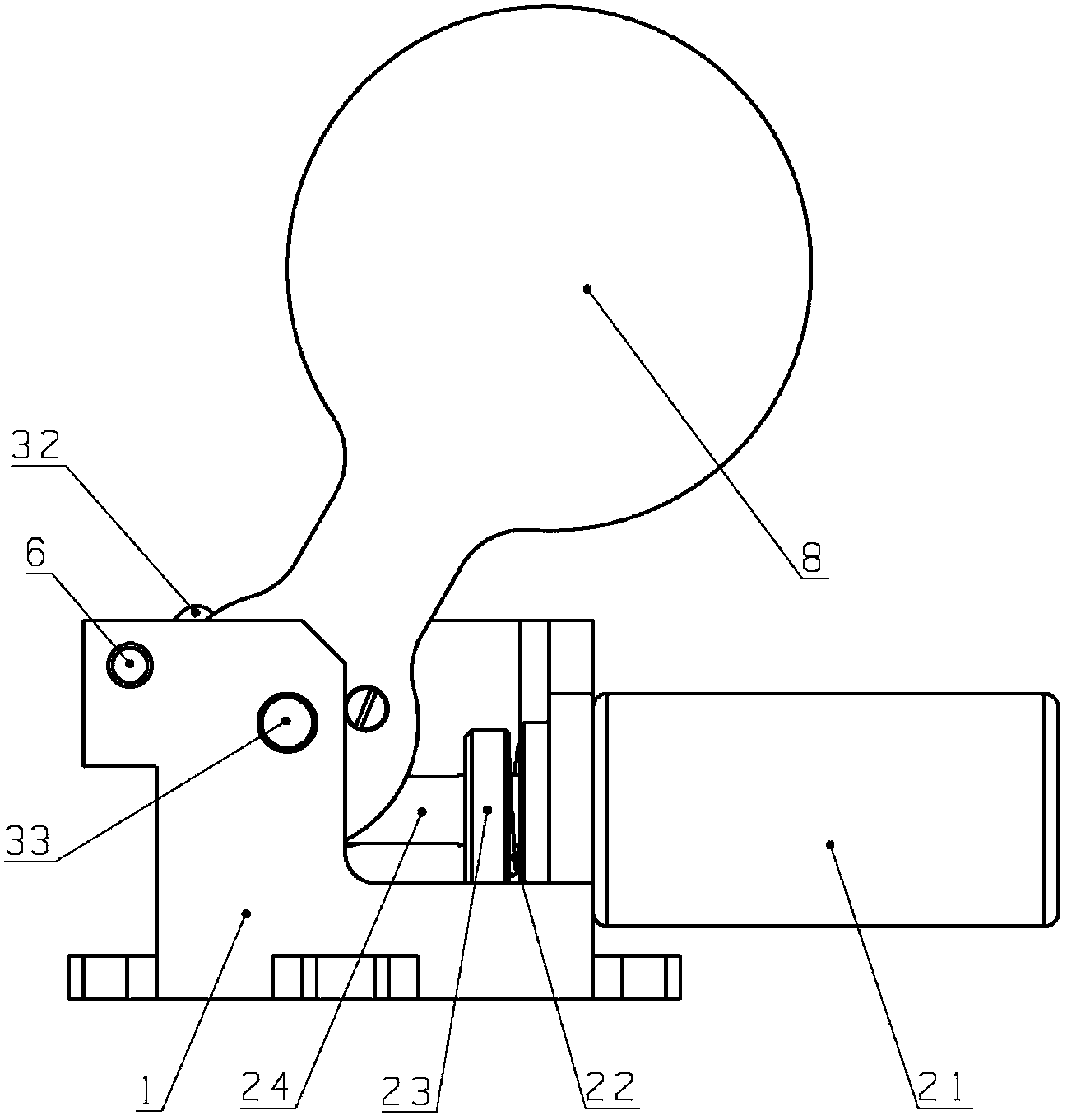

[0014] Reference Figure 1~5 The infrared camera non-uniformity correction device of the present invention includes: a base 1, a cylindrical electromagnet 2, a crankshaft mechanism 3, a pin 4, a limit rod 6, a closed state limit screw 5, a working state limit screw 7 and Shading plate 8. Among them, the crankshaft mechanism 3 is composed of a crank 31, a cam 32 and a crankshaft 33; the tube type electromagnet 2 is composed of a magnetic base 21, a compression spring 22, a spring base 23 and an iron core 24. One end of the iron core 24 is located in the cylindrical cavity of the magnetic base 21, the spring base 23 is fixedly connected to the iron core 24 by threads, and the compression spring 22 is located between the spring base 23 and the magnetic base 21. The pretension force of the compression spring 22 can be adjusted by adjusting the axial position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com