Automobile tail gas pipe temperature difference power generation device

A technology of automobile exhaust and thermoelectric power generation, which is applied to exhaust devices, mufflers, generators/motors, etc., can solve the problems of reducing manufacturing costs, increasing the weight of devices, affecting automobile exhaust emissions, etc., and achieving lightweight and easy installation of products. and disassembly, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

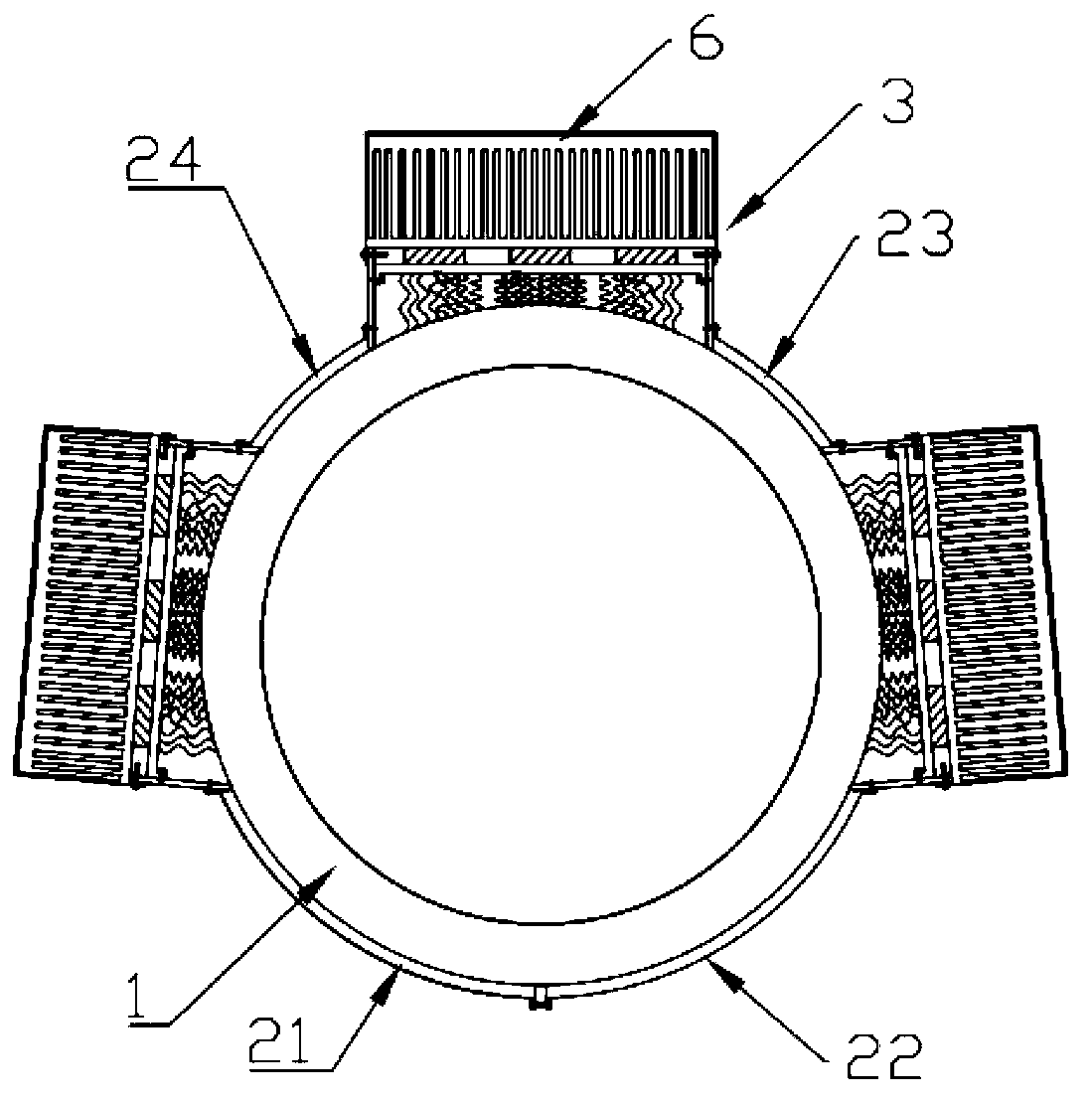

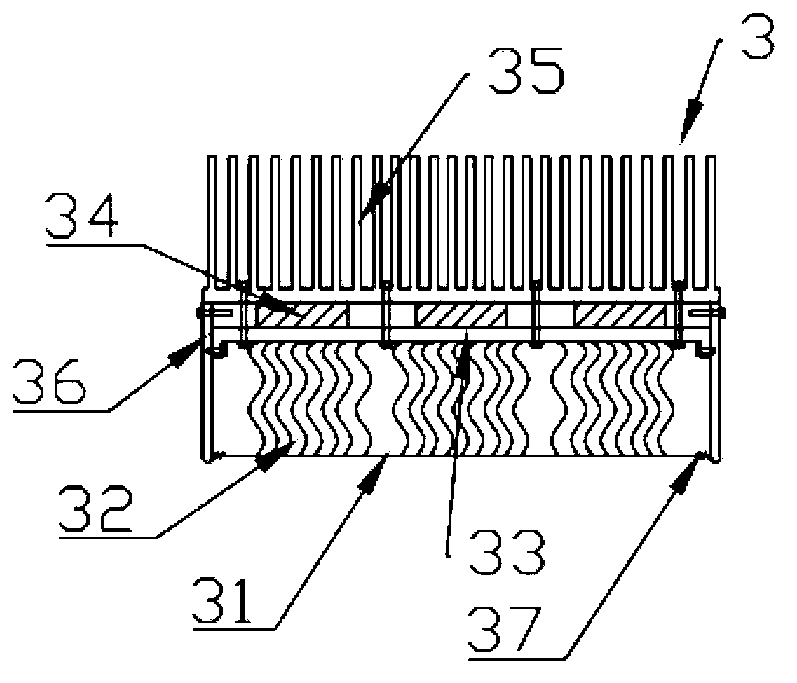

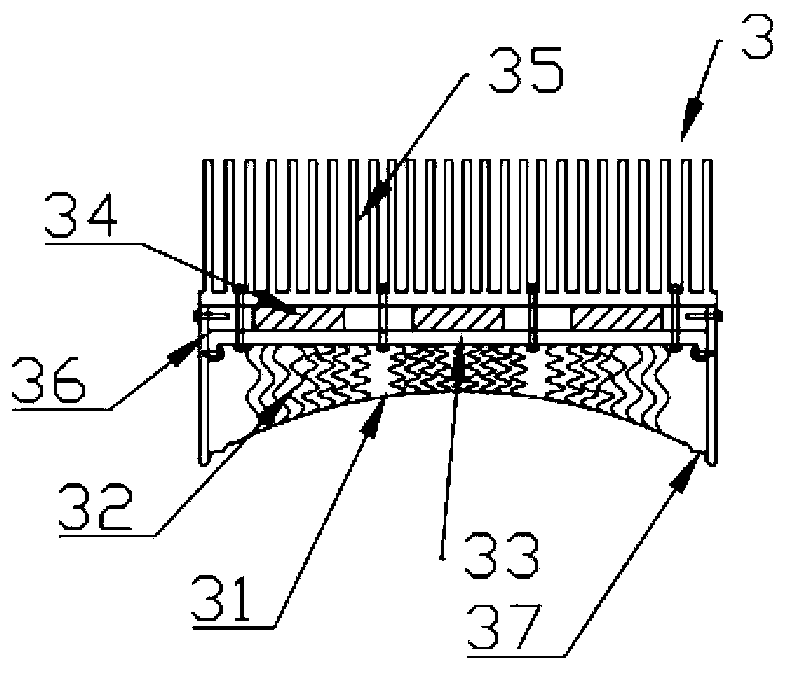

[0036] Figure 1 to Figure 4 The structure of an embodiment of the automobile exhaust temperature difference power generation device according to the present invention is shown. Such as Figure 1 to Figure 4 As shown, the automobile exhaust pipe thermoelectric power generation device of the present invention includes: at least two thermoelectric power generation modules 3 arranged on the outer periphery of the automobile exhaust pipe 1 along the circumferential direction of the automobile exhaust pipe, and each thermoelectric power generation module 3 includes a rigid substrate 33 , heat dissipation substrate 35, several thermoelectric chips 34 sandwiched between the rigid substrate 33 and the heat dissipation substrate 35, two heat shields 36 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com