Calender for smoothing a paper web

A calendering and leveling technology, which is applied in paper machines, calenders, papermaking, etc., can solve the problems of paper web surface keratinization, and achieve the effects of improving the leveling effect, improving heating, and good heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

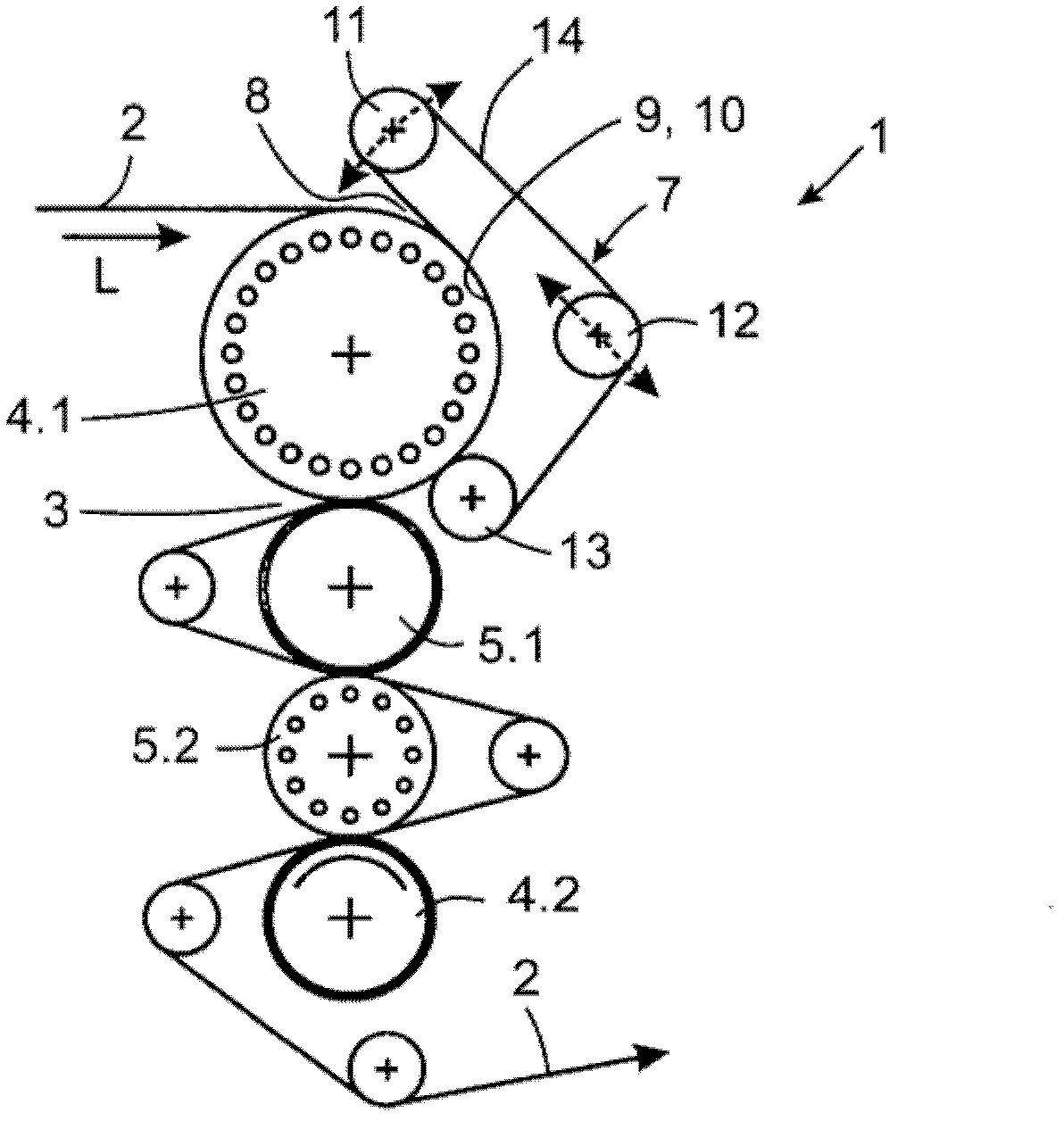

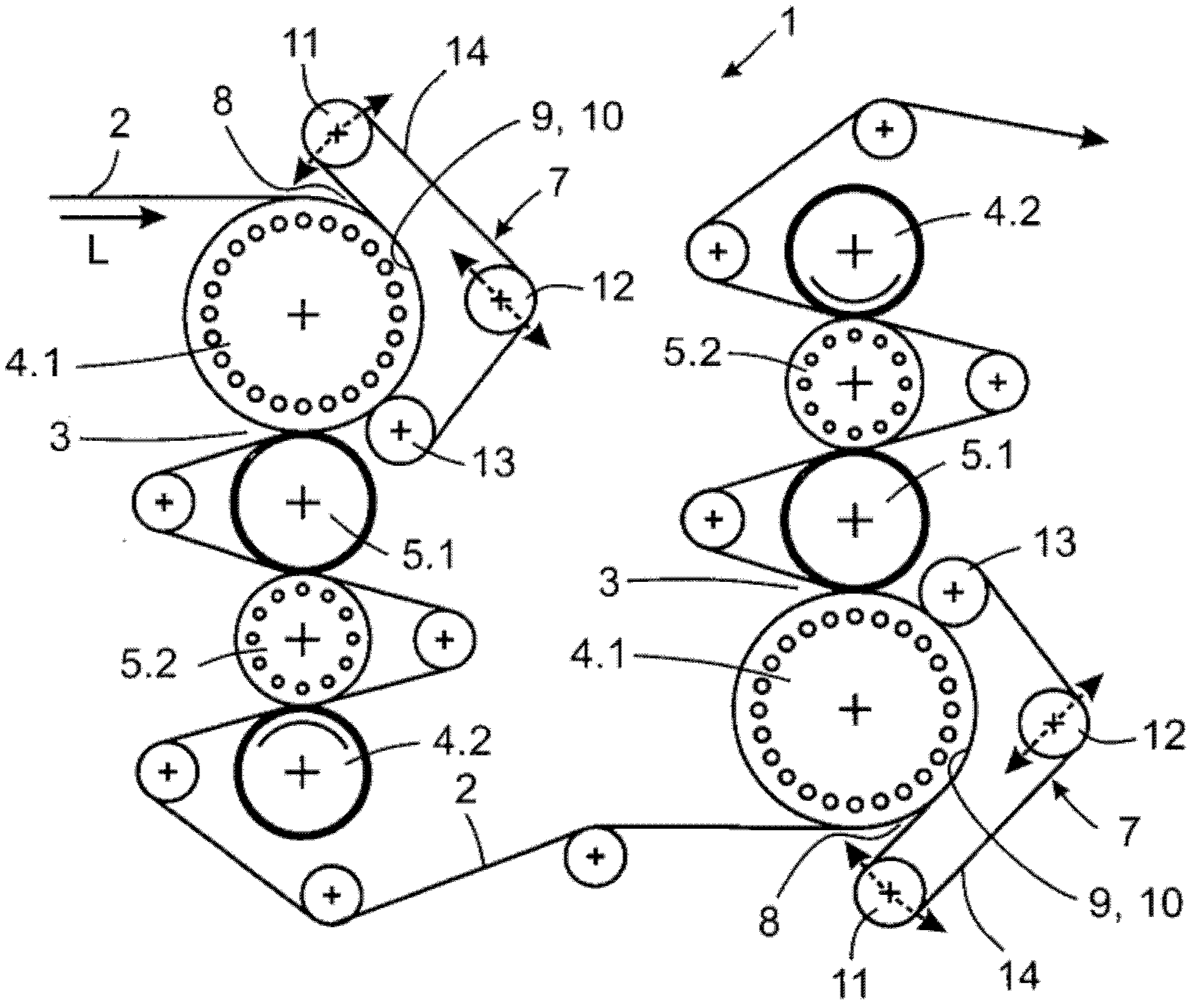

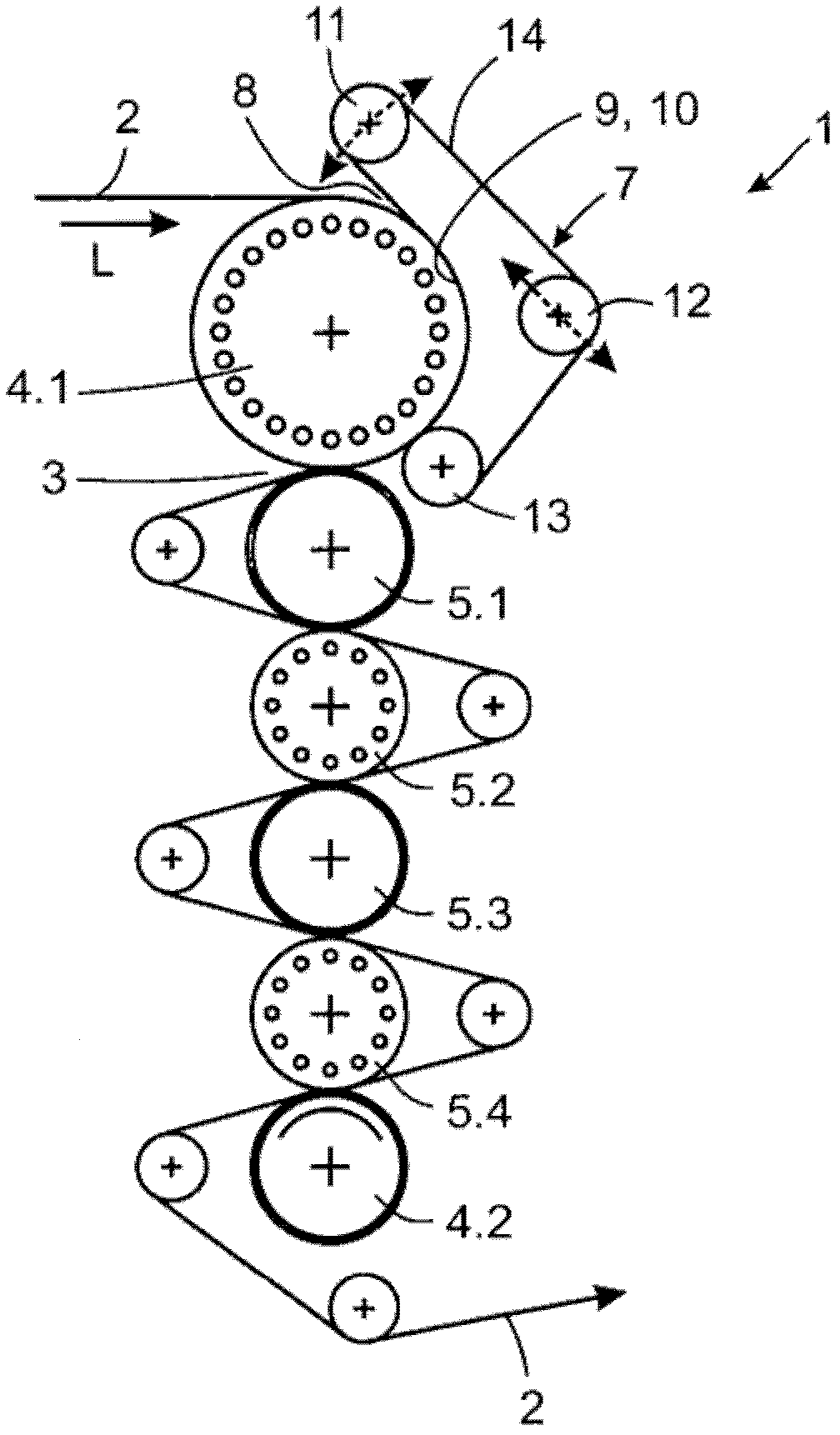

[0019] The invention relates to a calender 1 for smoothing a paper web 2, which consists in particular of gravure-printable paper. figure 1 A calender according to a first exemplary embodiment is shown schematically with at least one roll stack having an upper end roll 4.1 and a lower end roll 4.2 and intermediate rolls 5.1, 5.2. With regard to the guidance of the paper web 2 in the running direction L, one of the two end rolls, here the upper end roll 4.1, delimits the first working gap 3 of the roll stack. The roll stack comprises a plurality of rolls 4.1, 4.2, 5.1, 5.2, which are designed as hard rolls 4.1, 5.2 and soft rolls 5.1, 4.2 to form a loadable working gap in the form of a soft roll nip. The end rolls 4.1 delimiting the first working gap 3 are hard, heatable rolls with a diameter greater than the diameter of the hard, heatable middle roll 5.2. The outer wall of the end roll 4 . 1 also forms a contact surface 10 of the web processing nip 8 arranged upstream of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com