Method and apparatus for mixing fluids

一种混合流体、流体的技术,应用在混合方法、混合机、使液体与液体反应的化学方法等方向,能够解决高成本精炼厂装置等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1 - Fluid Mixer

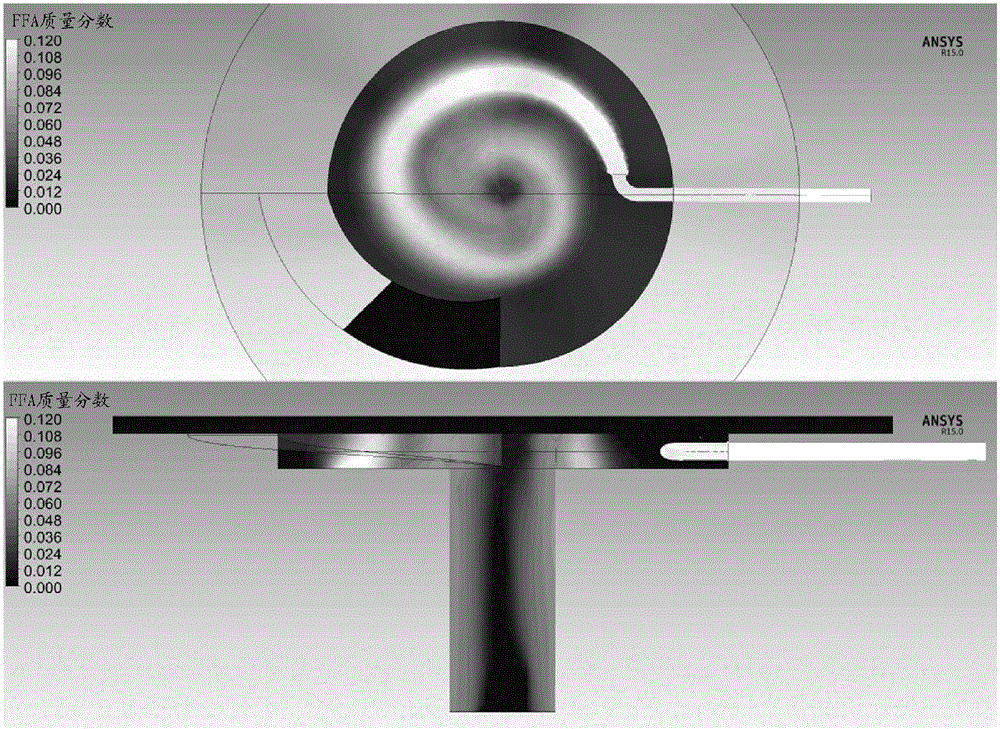

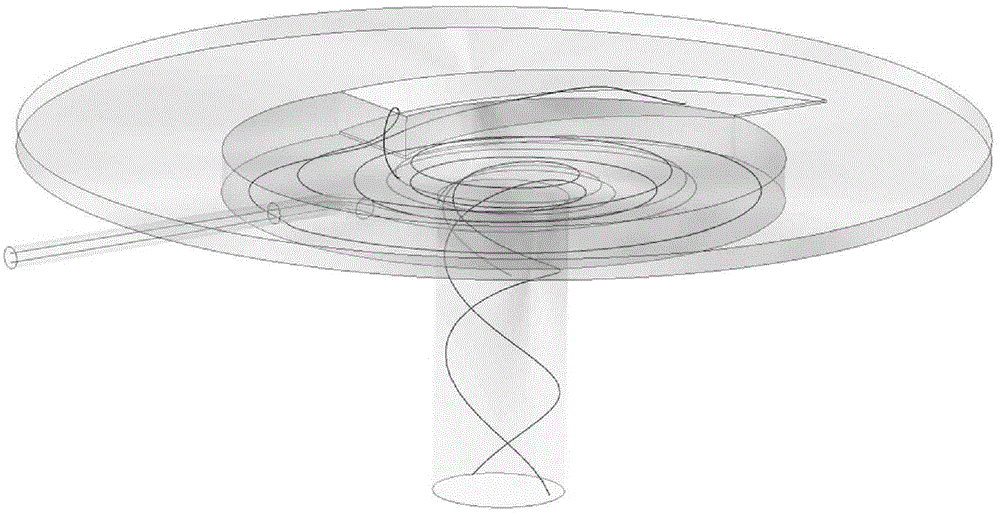

[0085] Assuming that the entire fluid mixer material can withstand 100% FFA, investigate the maximum FFA content of the feed. The material of the reactor wall is not changed and no additional protective layer is used in the reactor. Therefore, the fluid mixer was designed so that the FFA content close to the reactor wall did not exceed 12% by weight. One embodiment of the fluid mixer of the present invention is shown in figure 1 middle.

Embodiment 2

[0087] In this example, the fluid flow inside a fluid mixer is simulated. The first fluid enters the mixer from the top at 140t / h, and the second fluid is injected into the stream inside the mixer (see figure 1 ).

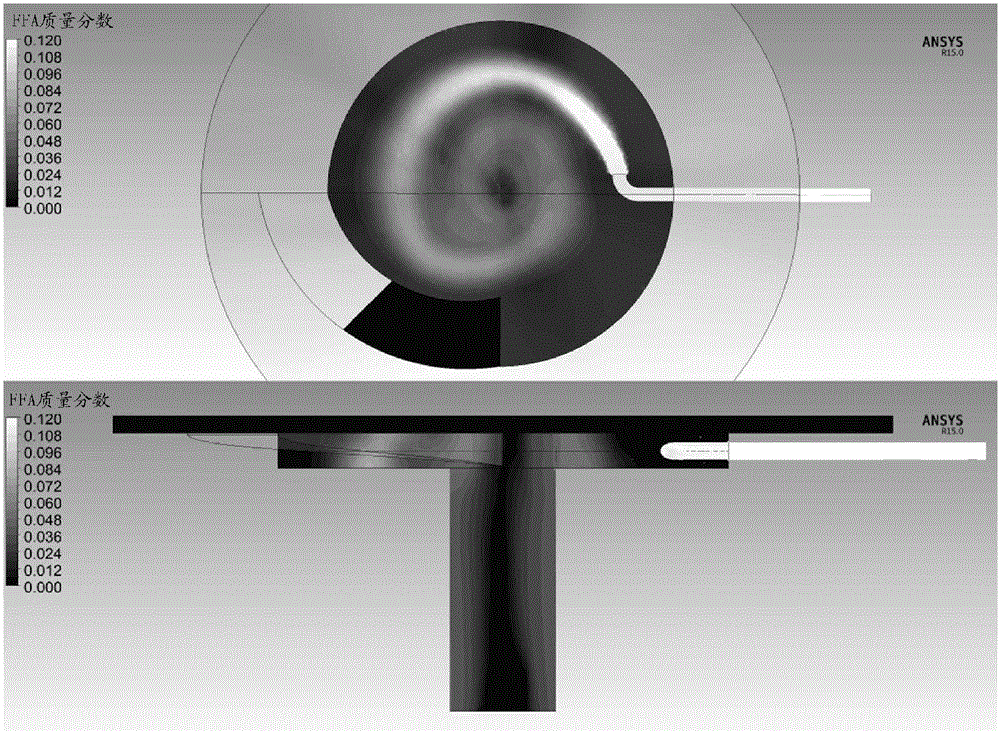

[0088] In order to increase the FFA concentration in the quench inlet (i.e., the second inlet), the simulated figure 1 The design shown in . FFA feed concentrations of 50, 80 and 100% by weight were used. Figure 2-4 FFA mass fractions are shown for specifications ranging from 0-12% by weight. Considering the 12 wt% FFA limit, 100 wt% FFA in the second fluid is acceptable if the wall can withstand up to 8 wt% or 12 wt%, depending on the quench tank material.

[0089] A CFD simulation of the FFA distribution inside the fluid mixer in the HDO reactor was performed. The simulations confirmed that the proposed fluid mixer is capable of effectively mixing the first fluid and the corrosive second fluid. Based on corrosion tests, the walls can withstand a maximum of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com