Concrete belt warehousing and transferring device and method

A technology of concrete and roller compacted concrete, applied in construction, infrastructure engineering and other directions, can solve the problems that the material flow cannot be transferred out in time, affecting the speed of entering the warehouse of the roller compacted concrete conveying system, etc., and achieve the effect of improving the construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

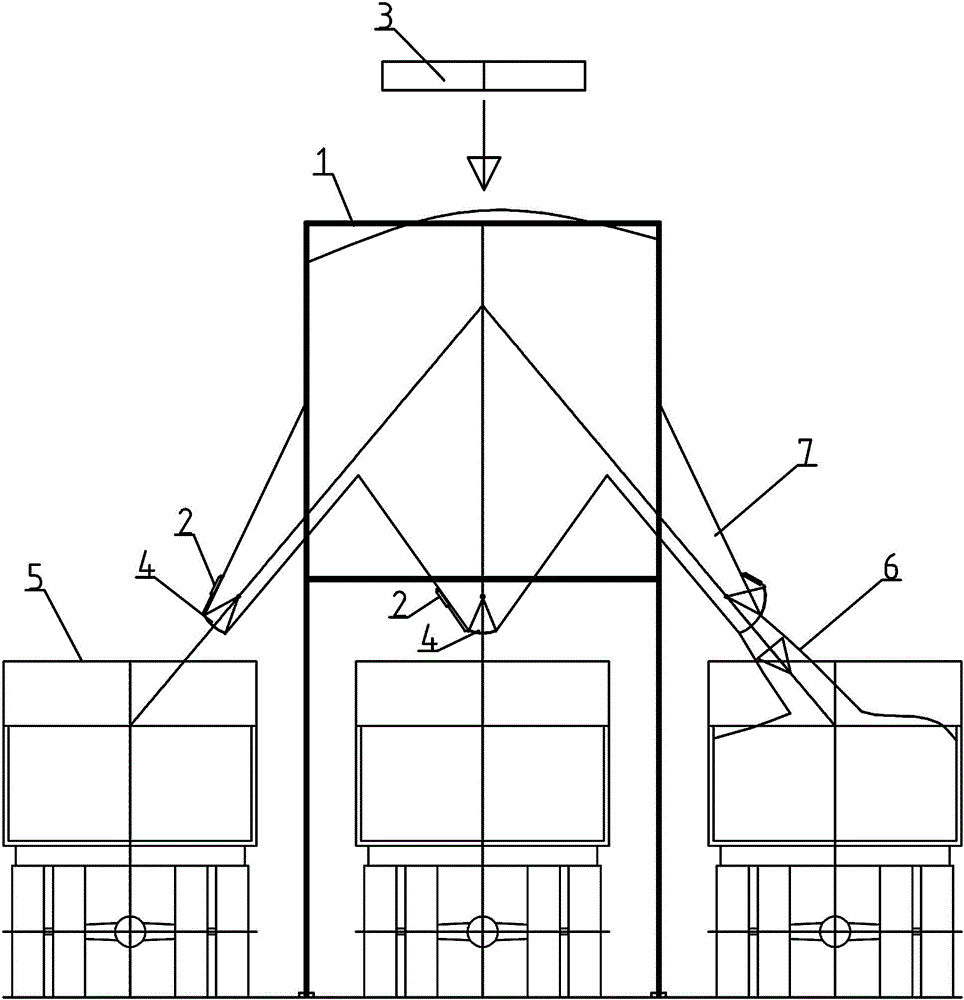

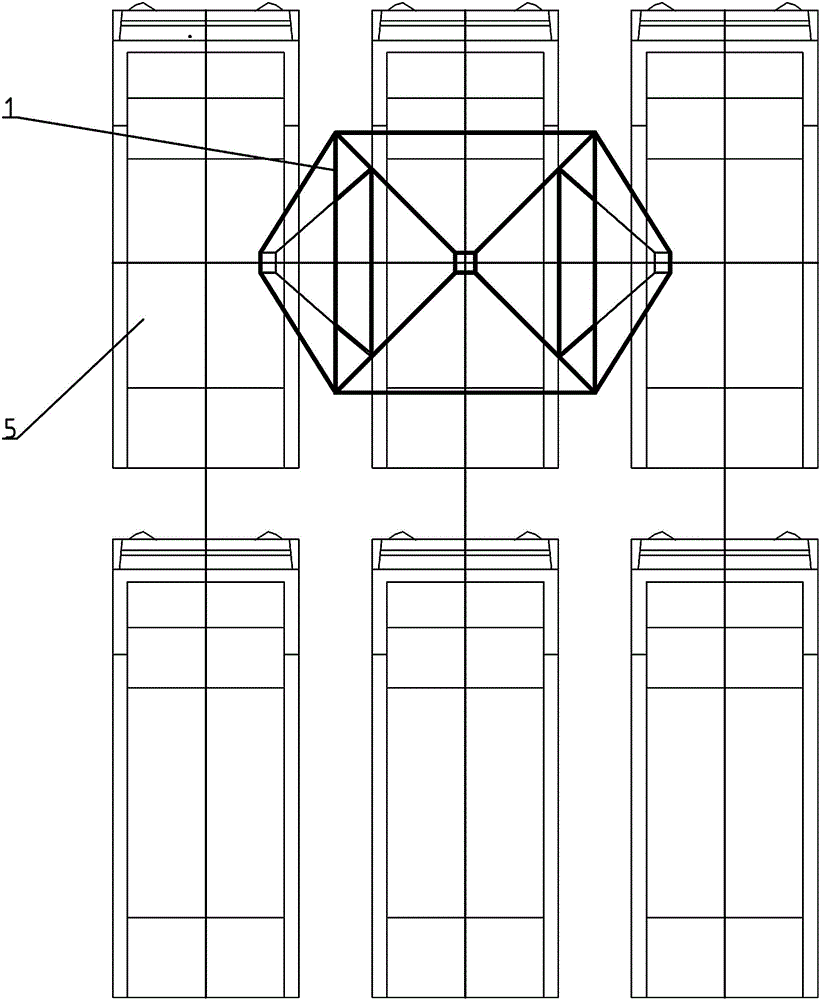

[0022] Such as figure 1 , figure 2 Among them, a concrete belt feeding and transferring device includes a belt feeding line 3, a hopper 1 is arranged under the belt feeding line 3, a plurality of discharge ports 7 are arranged under the hopper 1, and a plurality of discharge ports The port 7 is provided with a discharge door 4 .

[0023] The discharge door 4 is usually a hydraulic cylinder arc door.

[0024] According to the parameters such as the production capacity of the mixing plant, the conveying capacity of the feeding line, the construction strength, and the performance parameters of the dump truck, combined with the parameters such as the angle of repose of the RCC, the structure of the dump truck, and the discharge capacity, the opening and closing speed of the material door, and the material opening Due to the influence of arch plugs, it is designed and manufactured with 3 outlets on the left, middle and right, and a certain storage volume, the opening and closing...

Embodiment 2

[0027] A method for transferring concrete belts into warehouses, comprising the following steps:

[0028] A hopper 1 is set on the surface of the roller compacted concrete silo, and the hopper 1 is fed by the belt supply line 3, and three discharge ports 7 are set under the hopper 1, arranged according to the left, middle and right positions, and the three discharge ports Below the port 7, there are at most three rows of dump trucks 5 to supply the surface of the roller compacted concrete silo, and the concrete belt can be quickly transferred into the silo by the above-mentioned method.

[0029] In the optimized scheme, the inclination angle of the discharge port 7 located on the left and right sides is greater than the angle of repose of the concrete stream 6 . The distance between each discharge port 7 is greater than the width of the dump truck 5 . The distance between each discharge port 7 and the ground is greater than the height of the dump truck 5 .

[0030] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com