Concrete double-bracing large-scale mold plate and form stripping and form erecting methods

A concrete and double support technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problem of difficult to achieve mold area, and achieve the effect of shortening the construction period and improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

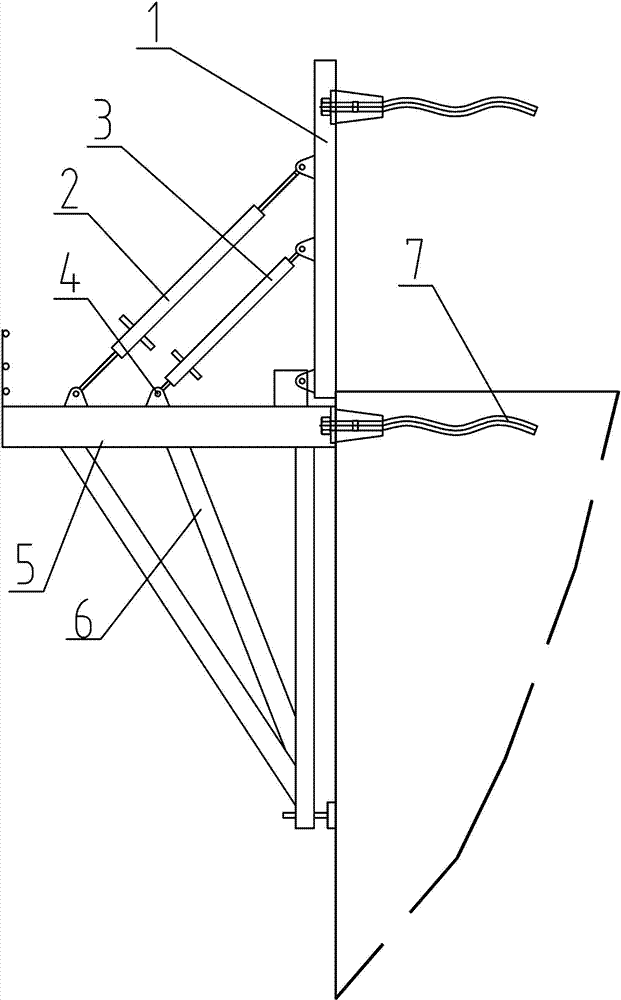

[0018] Such as figure 1 Among them, a concrete double-supported large-scale formwork, the lower end of the formwork 1 is hinged to the upper end of the triangular bracket 5, and the triangular bracket 5 is connected to the anchor bar 7 embedded in the concrete body;

[0019] The upper end surface of the tripod bracket 5 is connected to the back of the formwork 1 through at least two rows of first support adjustment screw rods 2 and second support adjustment screw rods 3 . The template 1 is over 4.5m in height. This results in a larger molding area.

[0020] In a further optimized solution, the second support adjustment screw 3 is located below the first support adjustment screw 2 .

[0021] The lower part of the triangular bracket 5 is provided with a plurality of diagonal braces 6, and each diagonal brace 6 corresponds to the force-bearing position of the first support adjustment screw 2 and the second support adjustment screw 3 respectively.

[0022] The formwork 1 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com