Steel pipe column concrete casting construction method employing cavern-pile method

A construction method and technology for steel pipe columns, applied in construction, infrastructure engineering and other directions, can solve the problems of high viscosity, deviation of the steel pipe column from the center line, affecting the pouring quality of the steel pipe column, etc., so as to reduce the material cost and improve the pouring construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

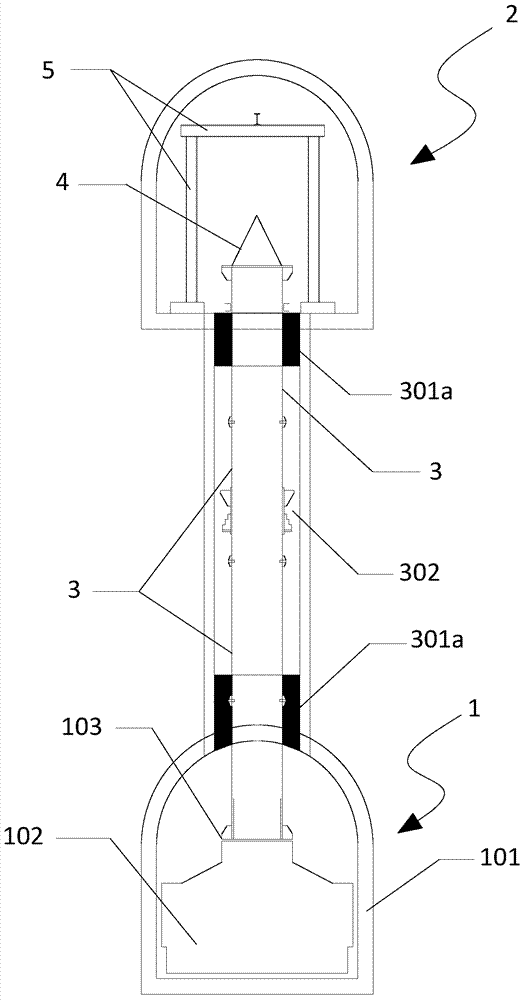

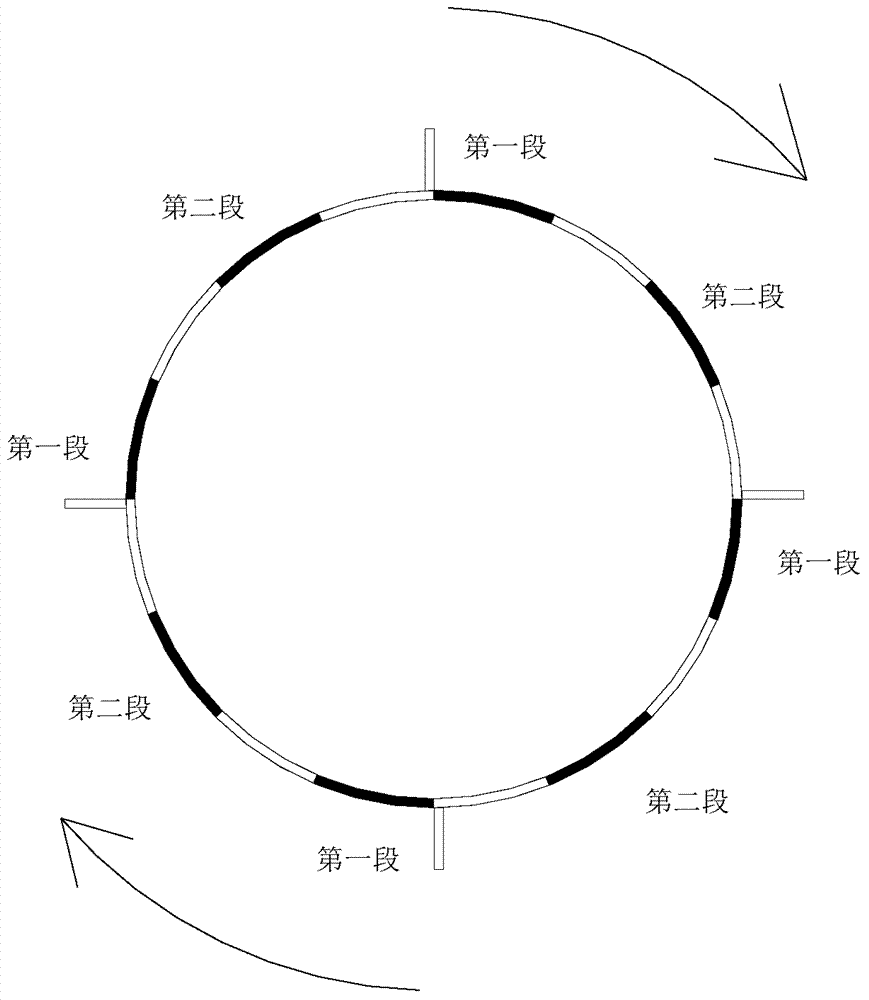

[0026] In the excavation construction of a certain subway, after the steel pipe columns are hoisted in place, the construction method of the present invention is adopted. The steel pipe column is welded by a symmetrical welding method, and the welding process is divided into several steps, such as figure 2 As shown, first set the figure 2 The first section directly above and directly below (note: the black part) shown in , are symmetrical to each other, and the welding arc length is about 1 / 4πR (note: R is the radius of the steel pipe column, and the corresponding error range is 10%). Then turn clockwise 90°, weld the same length again, about 1 / 4πR, figure 2 The first paragraph on the left and right of the center (note: the black part). Finally, the figure 2 The part marked in the second paragraph is divided into symmetrical welding again. According to the actual situation, it can also be welded from the counterclockwise direction. The key is to weld symmetrically to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com