Thermal insulation expansion joint of reducing adapter tube

An expansion joint and temperature insulation technology, which is applied in the field of expansion joints, can solve the problems of structural discontinuity, decrease in joint strength, stress concentration, etc., and achieve stable and reliable temperature insulation effect, avoid lining falling off, and smooth medium flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

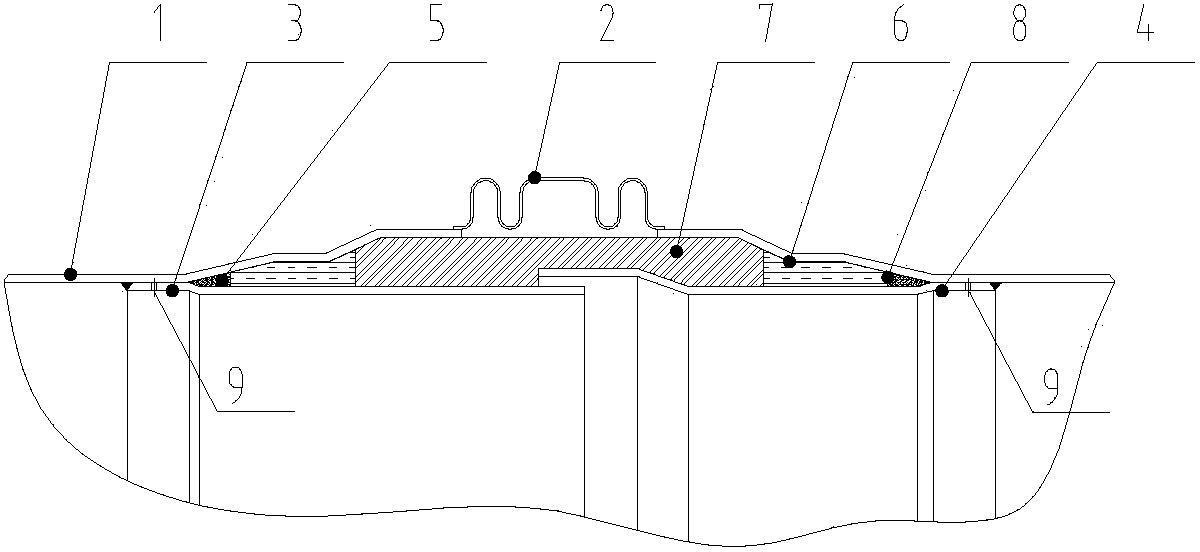

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Such as figure 1 As shown, the two ends of the corrugated pipe 2 of the present invention are connected with the reducing pipe 1; 2. The variable-diameter lining pipe 2 4 holes along the circumference of the variable-diameter fitting part, and the opening part is connected with the variable-diameter connecting pipe 1, and the hole is a round hole or an oval hole plug welded 9; the variable-diameter lining pipe 1 3. The opposite end of the inner liner pipe 24 is as follows figure 1 Cross-combined with each other, together with the reducing pipe 1 and the bellows 2, they form a temperature-insulating cavity. The temperature-insulating cavity is divided into three parts. The temperature-insulating layer 15 is filled with heat-resistant silicon cloth at the position shown in the figure. And at the junction of the temperature insulation layer 5 and the temperature insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com