Cotton carding dust filtration air return device

A filtering device and dust filtering technology, which is applied in ventilation systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of high power consumption of heating facilities, which is not conducive to energy saving and consumption reduction, and achieve energy saving for air conditioning , simple structure, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

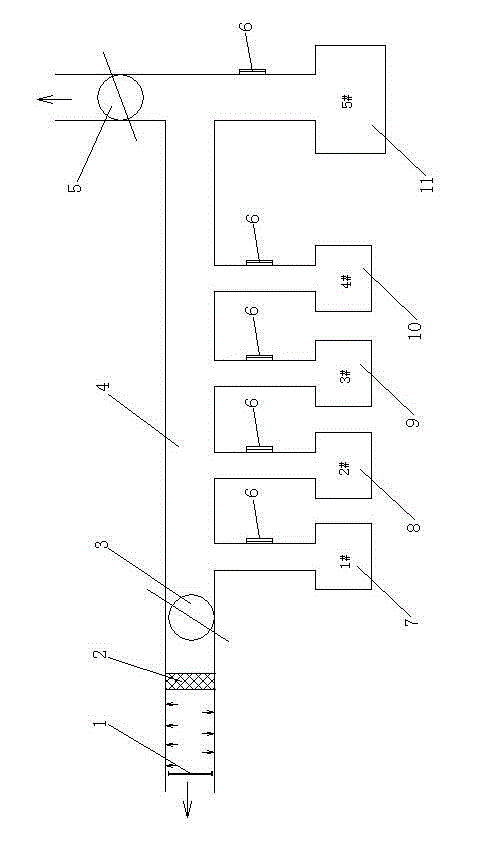

[0014] as attached figure 1 As shown, a carding dust filter return air device includes five sets of 1#-5# dust filter return air ducts, and each set of dust filter return air ducts is respectively communicated with a main duct 4 through an air duct, and one end of the main duct 4 is connected to the Inside the workshop, the other end is connected to the outside of the workshop. An exhaust window A3 and a filter device 2 are provided at the end of the main pipeline 4 communicating with the workshop, and an exhaust window B5 is provided at the end of the main pipeline 4 communicating with the outside of the workshop.

[0015] In this embodiment, in order to ensure that the return air sent to the workshop maintains a certain humidity, the end of the main pipe 4 communicating with the workshop is also provided with a spray device 1, which is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com