Wavelength conversion apparatus and luminous apparatus

A wavelength conversion device and wavelength conversion layer technology, applied in the optical field, can solve the problems of insufficient LED brightness, high cost of blue laser, and low service life, and achieve the effect of reducing etendue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

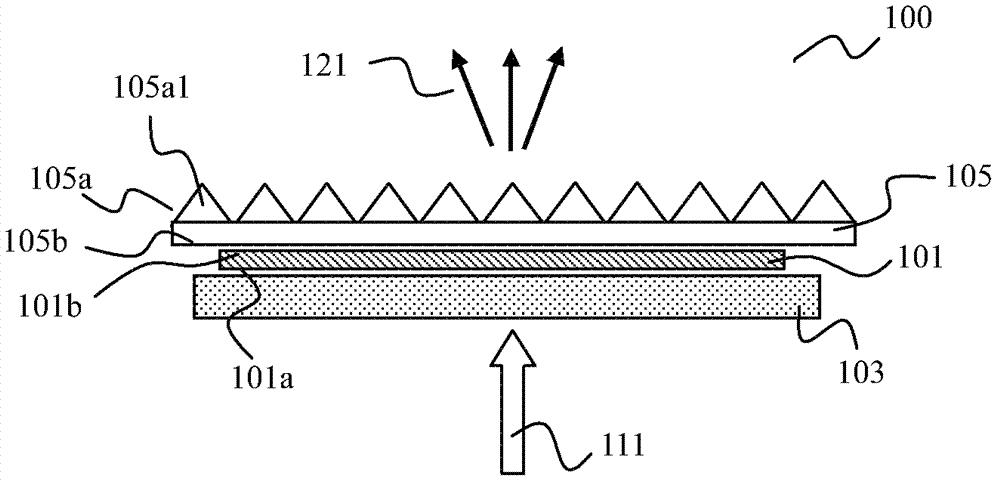

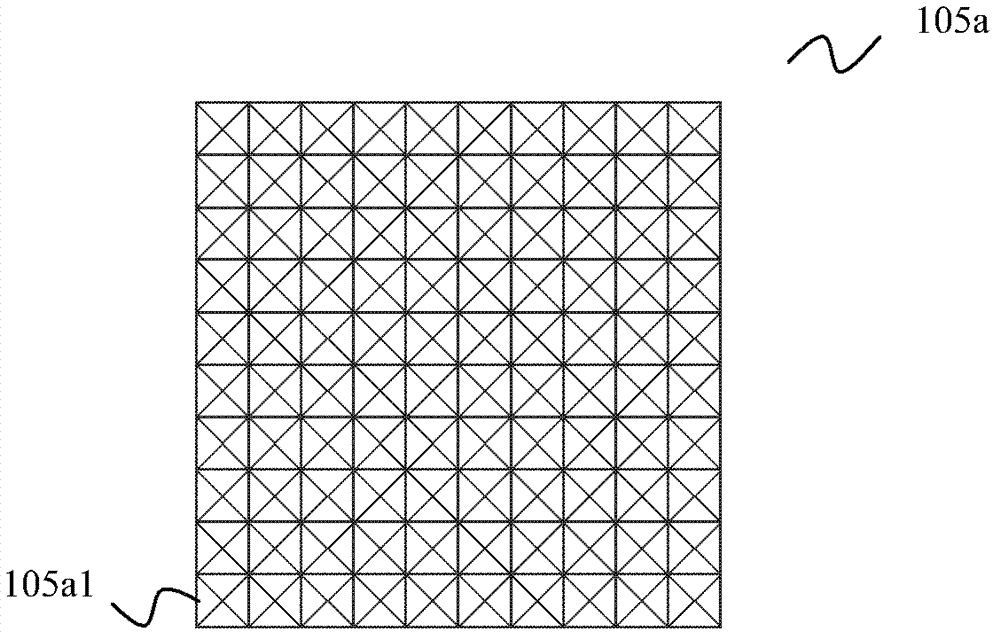

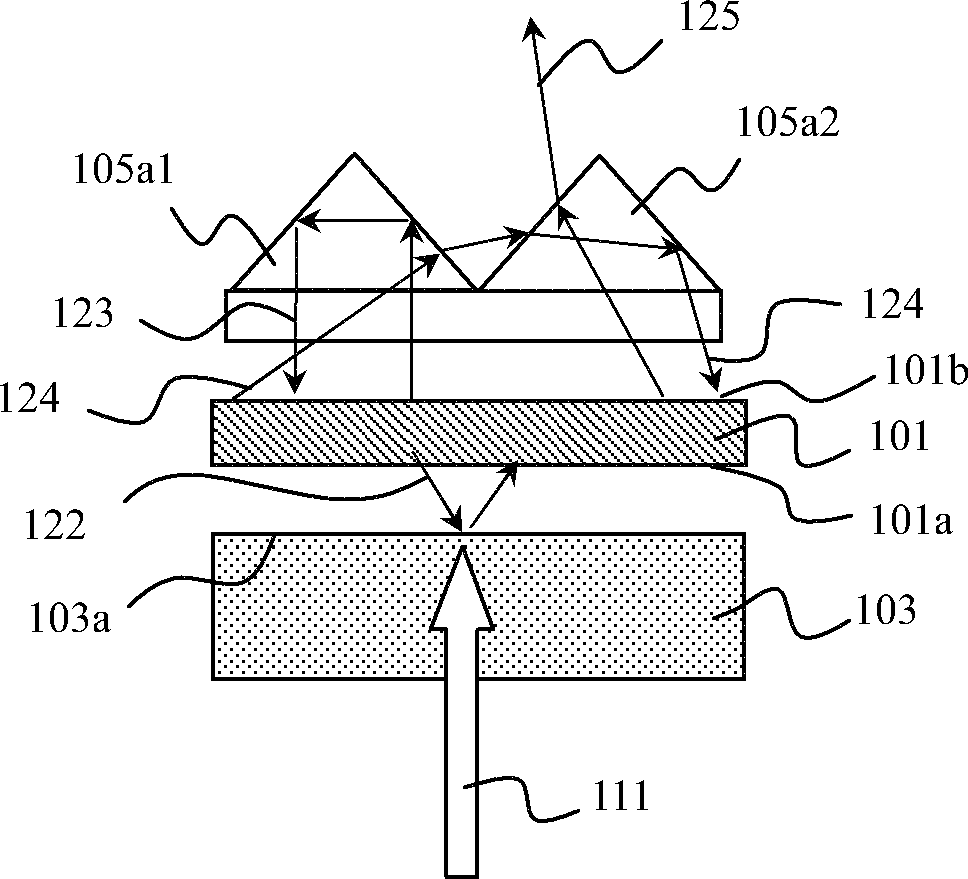

[0018] The structure of the first embodiment of the present invention is as Figure 1a shown. The wavelength conversion device 100 includes a wavelength conversion layer 101 for absorbing the excitation light 111 and emitting the received light 121. The wavelength conversion layer 101 includes opposite first surfaces 101a and second surfaces 101b; A reflective layer 103 on one side, the reflective layer 103 reflects the received light; it also includes a light distribution transformation layer 105 located on the second surface 101b side of the wavelength conversion layer, and the light distribution transformation layer 105 includes an opposite plane 105b and a microstructure surface 105a , the plane 105b faces the second surface 101b of the wavelength conversion layer, and the microstructure surface 105a includes a plurality of microstructure units 105a1.

[0019] The light distribution conversion layer is made of transparent materials, such as glass or transparent organic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com