Connection lamp holder

A technology for connectors and lamp holders, which is applied in the direction of connection, parts of connection devices, discharge lamps, etc., can solve the problem that the convenience of one-time connection cannot be realized, the process of installation and wiring cannot be simplified, and it consumes a lot of manpower and material resources. and other problems to achieve the effect of simplifying the wiring steps and operability, not easy to pull out or disengage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

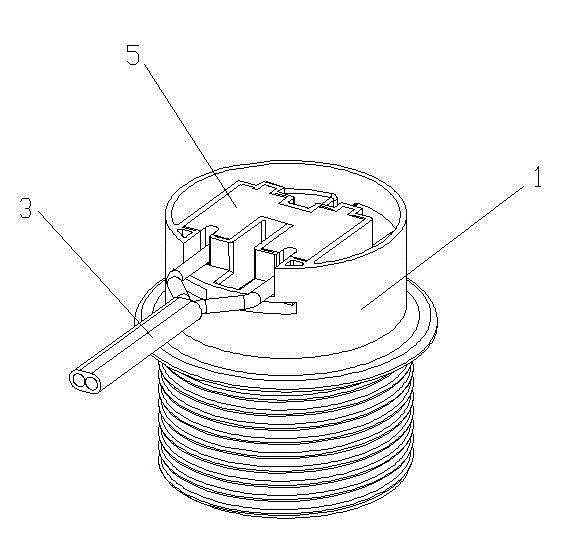

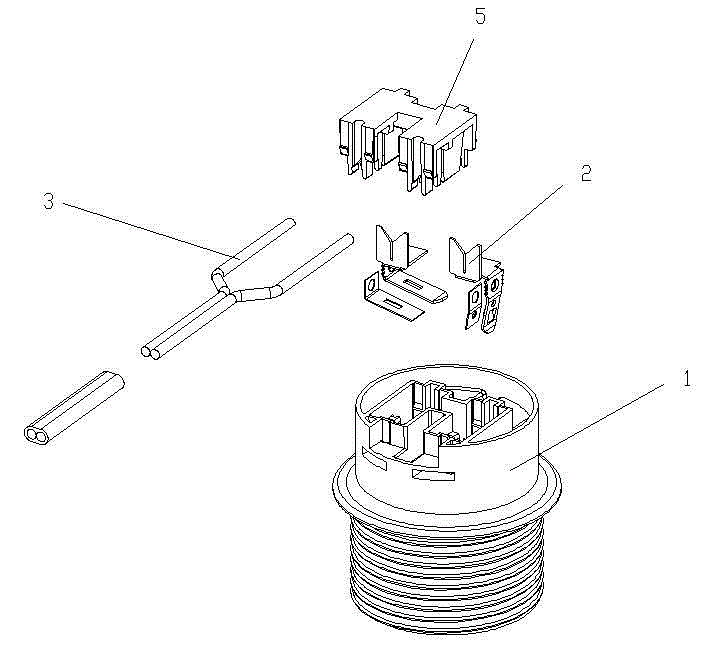

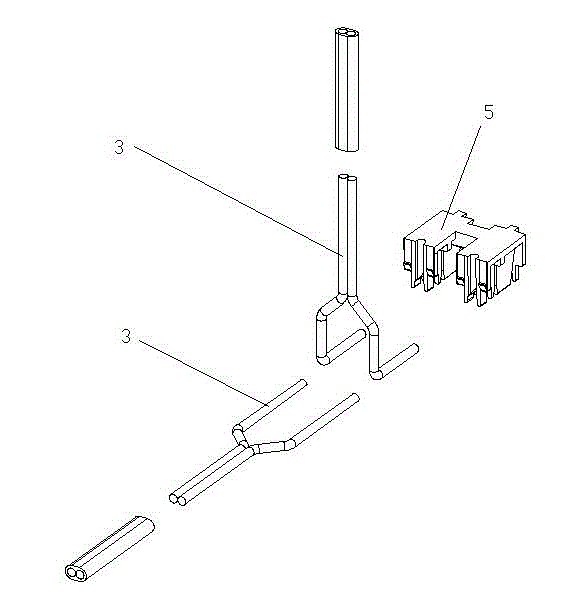

[0019] A connected lamp holder described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the connection lamp cap includes an insulated connector 1, a pair of conductive metal sheets 2 that can be connected to external wires are arranged inside the insulated connector, and a socket 4 that allows the wire 3 to pass through is provided on the outside of the insulated connector. There is an insulated connection terminal 5, the bottom of the connection terminal is provided with a slot 6 corresponding to the socket, and one end of the conductive metal sheet is provided with a connection structure 7 that can cut the insulation layer of the wire and contact the core wire of the wire when the wire is inserted into the connection terminal. The wiring structure is as follows: a V-shaped opening 11 is provided at one end of the conductive metal sheet corresponding to the through slot, and a strip-shaped op...

Embodiment 2

[0023] This embodiment 2 is changed on the basis of embodiment 1, specifically the structural changes to the wiring structure, specifically: the structure of the wiring structure in this embodiment 2 is as follows: Figure 7 As shown, one end of the conductive metal sheet 5 corresponding to the notch is provided with a V-shaped opening, the root of the V-shaped opening extends with a strip-shaped opening with a width greater than the diameter of the wire core wire, and a sharp needle 8 is provided at the root of the strip-shaped opening. The plane of the V-shaped opening is at an oblique or perpendicular angle to the wire insertion angle. In this way, the aforementioned sharp puncture needle can also simply and smoothly pierce the wire insulation layer and directly contact with the wire core wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com