Electrically-assisted magnetic core power machine

A power machine and magnetic core technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of unbalanced driving speed, insufficient driving force, and instability, and achieve the effect of balanced and stable rotation, controllable speed, and sufficient power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

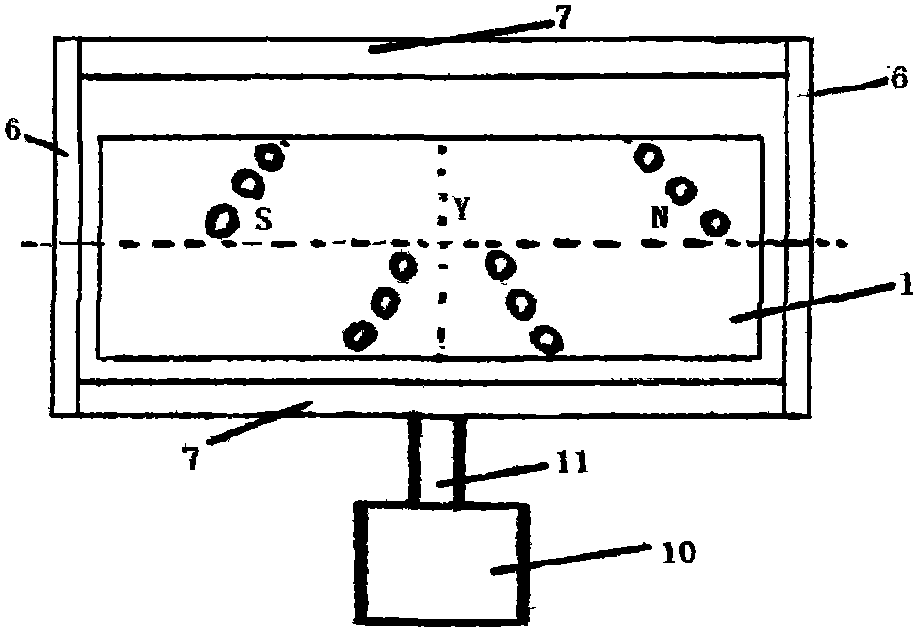

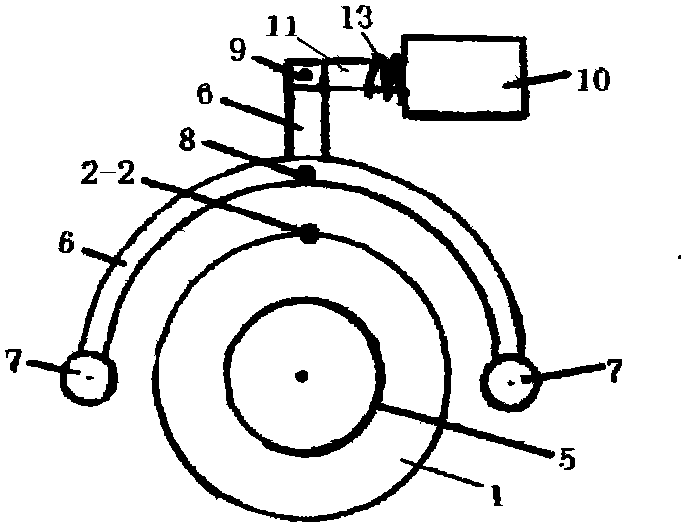

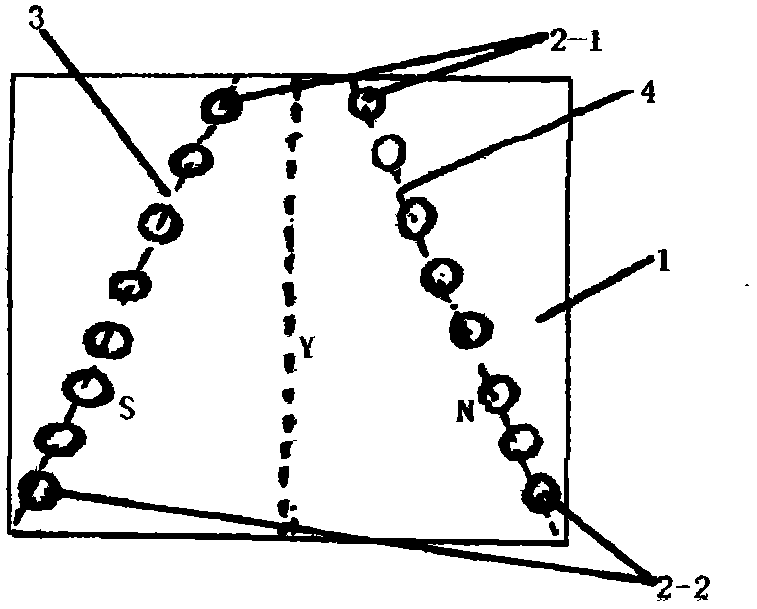

[0009] The present invention will be further described through embodiment now in conjunction with accompanying drawing. Such as Figure 1-6 As shown, a set of magnet groups composed of several magnetic blocks 2 is provided on the peripheral wall of the rotor 1, and the magnet group is formed by a plurality of magnet blocks 2 in two rows along the circumferential direction of the rotor 1 and distributed at equal intervals on the radial direction line on the peripheral surface of the rotor 1. On the y side, along the circumferential direction of the rotor 1, it is formed on the oblique lines 3 and 4 of the two Swiss directions of the rotor 1. The slopes of the two oblique lines 3 and 4 are equal and symmetrical to the radial direction line y. The two magnetic blocks 2 on the opposite left and right sides on the same axial direction line on the peripheral wall of the rotor 1 have opposite polarities (respectively N and S poles) and form a pair with each other. The magnetic bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com