Device for collecting liquid samples from a vat

A technology for collecting liquids and samples, applied in sampling devices, measuring devices, sampling, etc., can solve problems such as inability to collect samples, excess liquid that cannot be completely returned to the vat, and difficulty in joining the vat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

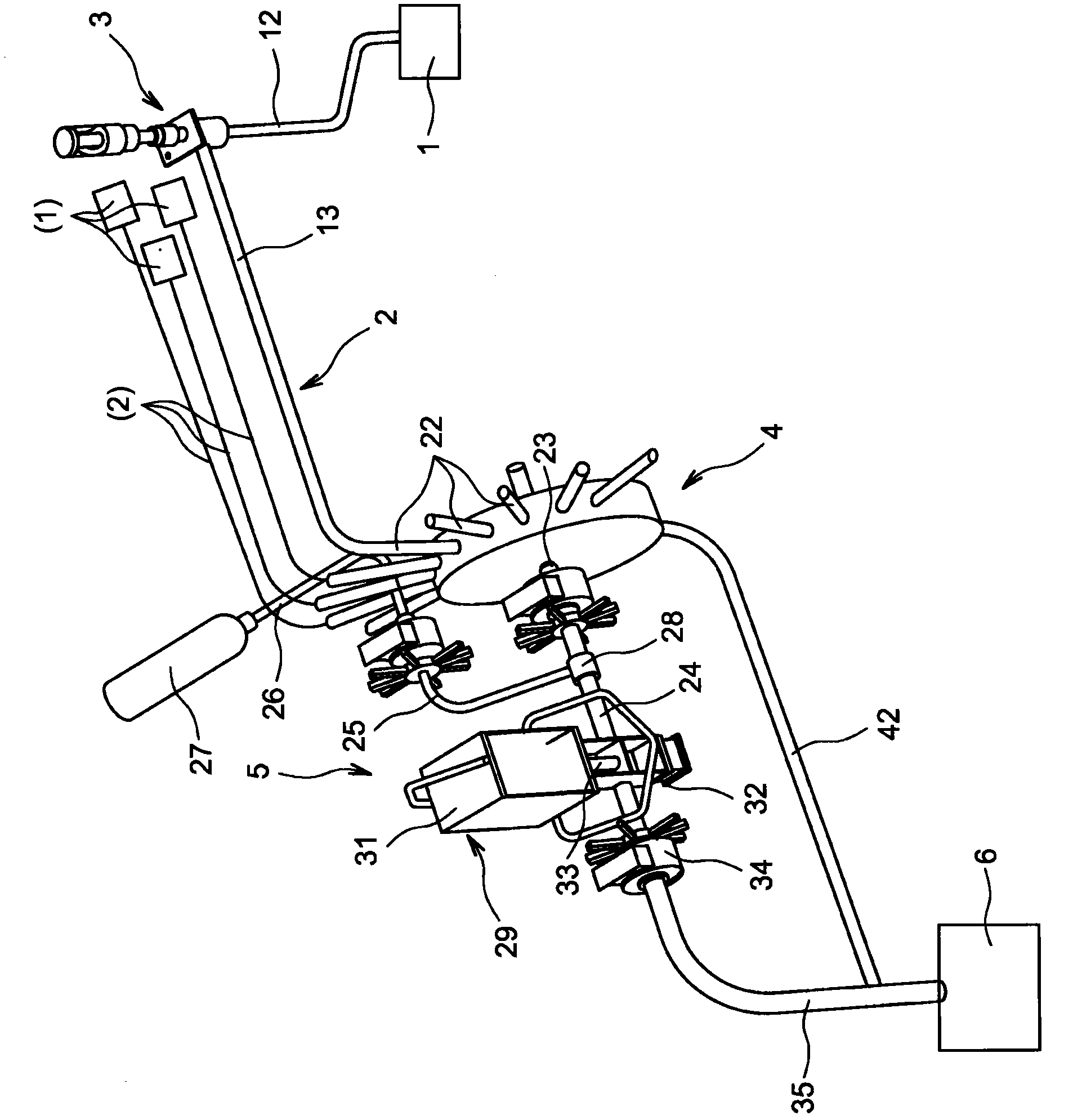

[0014] see first figure 1 . The liquid to be sampled is initially located in storage vat 1 . The conduits 2 for sampling leave the top of the vat 1, pass through the sampling facility 3, are each connected to a joint selector 4, then pass through the suction unit 5, and terminate at the outlet 6, which is used to collect excess Reservoir for suction liquid. The main elements of the device will now be described in turn. The conduit 2 first ascends from the vat 1 to the sampling facility 3 and then gradually descends towards the outlet 6, which is opposite the vat 1 and thus separated therefrom.

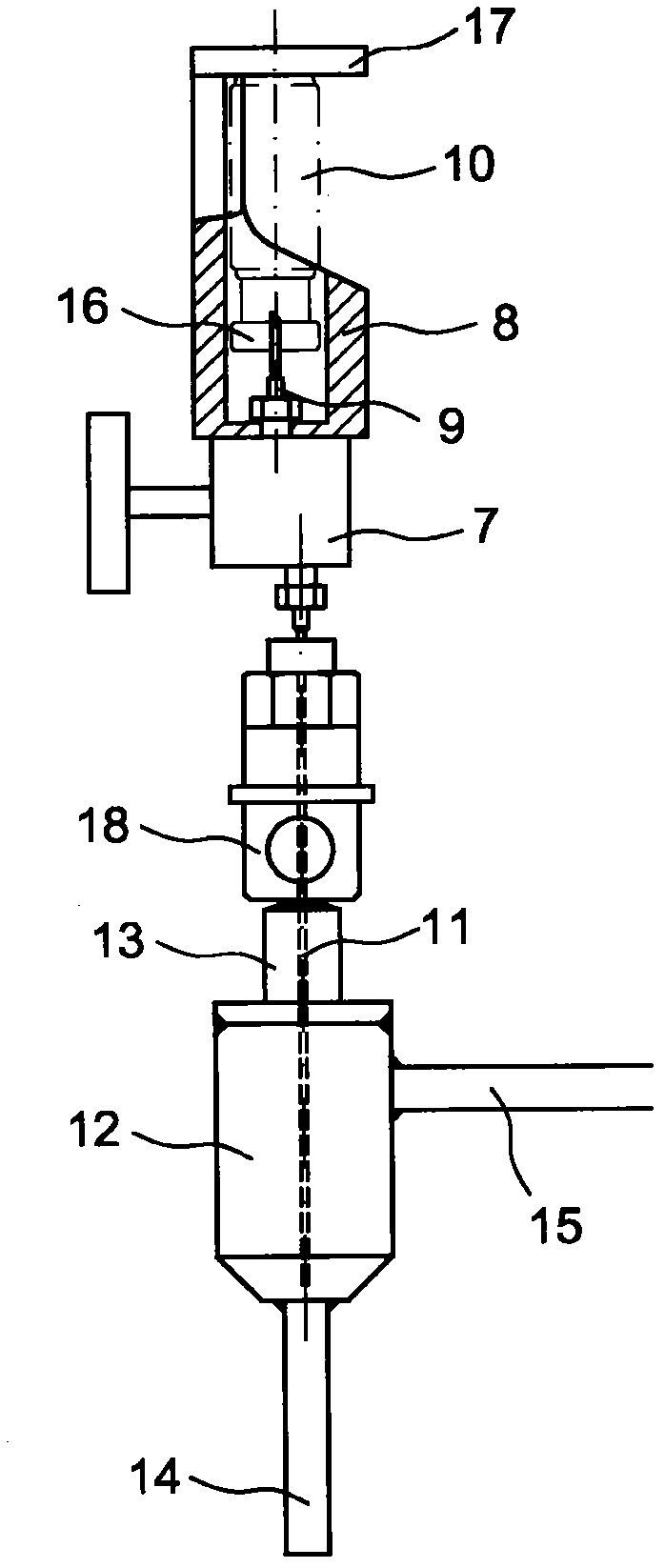

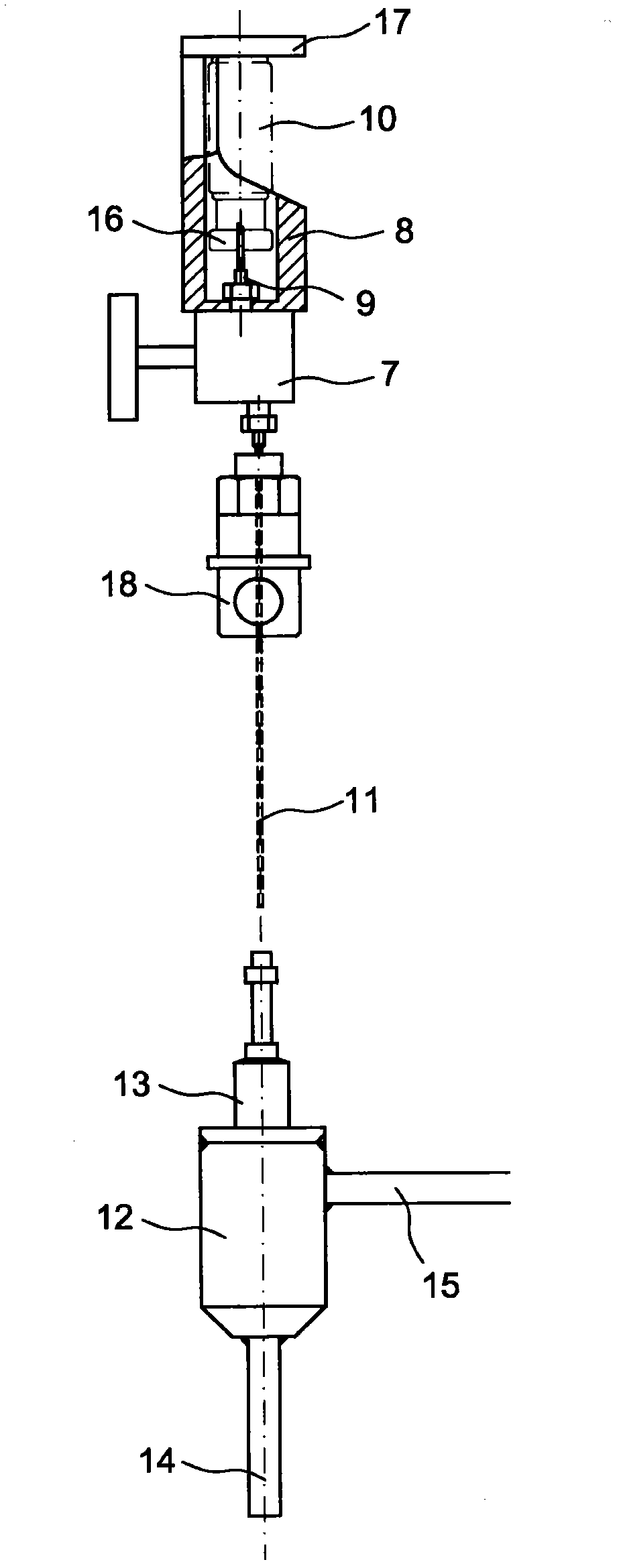

[0015] Figure 2 shows the sampling system 3 in detail. The sampling system 3 firstly comprises a movable part constituted by a manual valve 7 and a base via an injection needle 11, wherein the top of the manual valve 7 is occupied by a cylindrical sleeve 8 open at the top, which contains the upper Install the upper injection needle 9 of the liquid tank 10 and the pivoting part 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com