Multifunctional double tank drug feeding system

A dosing system and multi-functional technology, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of slow dosing, restricting petroleum purification and its industrial use, and difficult to control. It is convenient for the current assembly work, convenient for long-distance transportation, and the effect of solving the inconvenience of water and electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

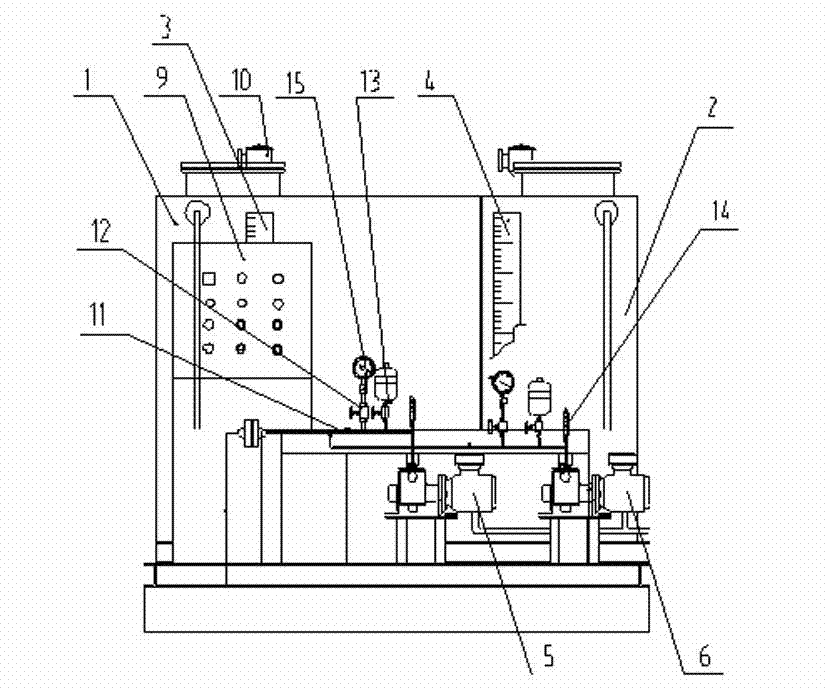

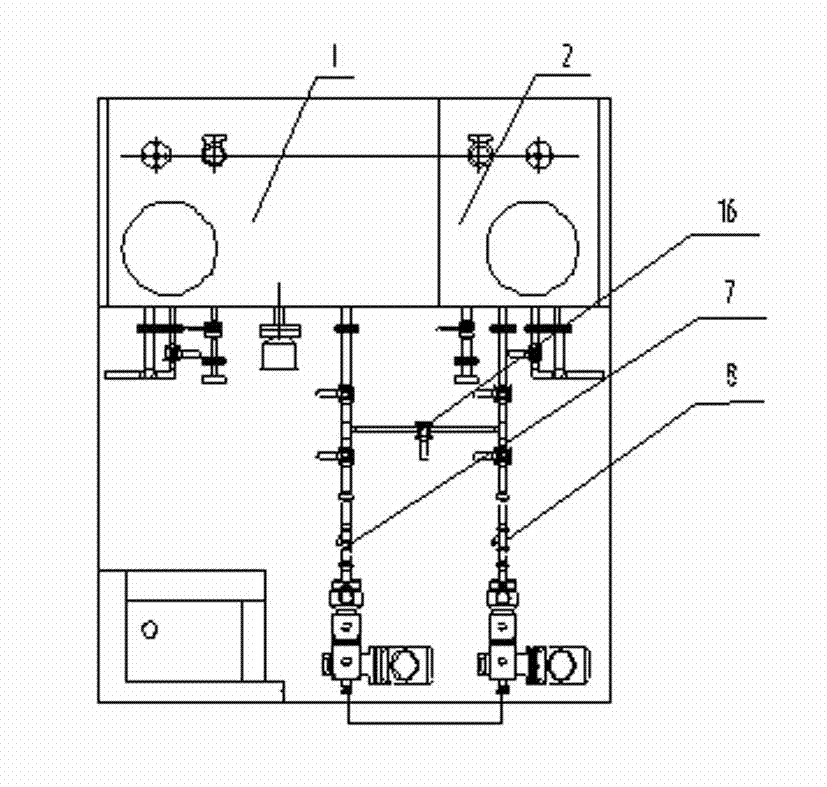

[0019] Such as figure 1 with figure 2 As shown, a multifunctional double-tank dosing system includes a material tank 1, a material tank 2 2, a liquid level gauge 3, a liquid level gauge 4, a metering pump 5, a metering pump 2 6, and a filter 7. Filter two 8 and dosing control device 9; material tank one 1 and material tank two 2 are divided into different liquid medicines; material tank one 1 and metering pump one 5 are connected through pipelines, and filters are arranged on the pipelines One 7; the material tank two 2 and the metering pump two 6 are connected through a pipeline, and the pipeline is provided with a filter two 8; the material tank one 1 is provided with a liquid level gauge one 3, and the material tank two 2 is provided with a liquid level gauge Two 4; dosing control device 9 is respectively connected with liquid level gauge one 3, liquid level gauge two 4, metering pump one 5 and metering pump two 6, and is controlled by the high and low levels of liquid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com