Mold rotation type injection molding machine and rotary table rotation method

An injection molding machine and rotary technology, applied in the field of mold rotary injection molding machine and its turntable rotation, to achieve the effect of reducing costs and ensuring design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

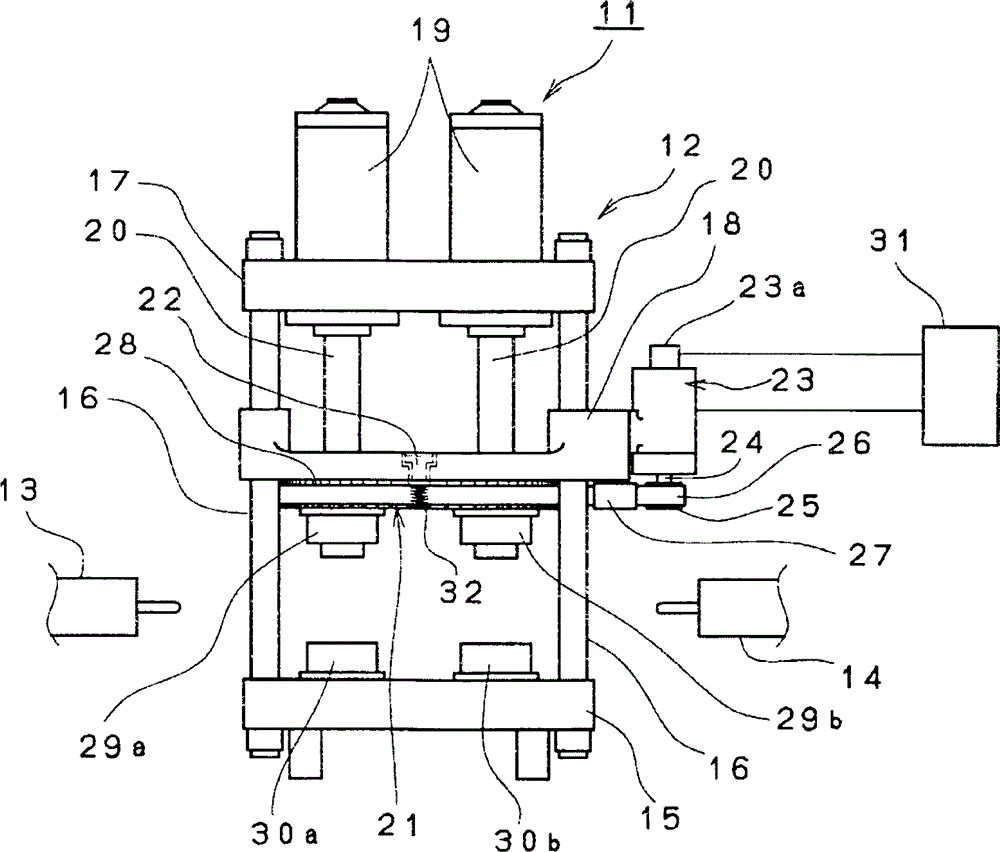

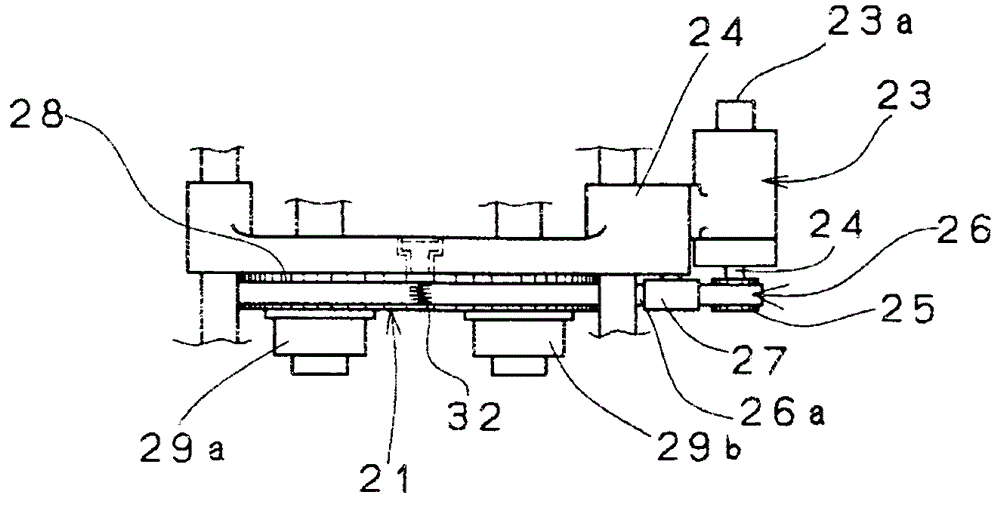

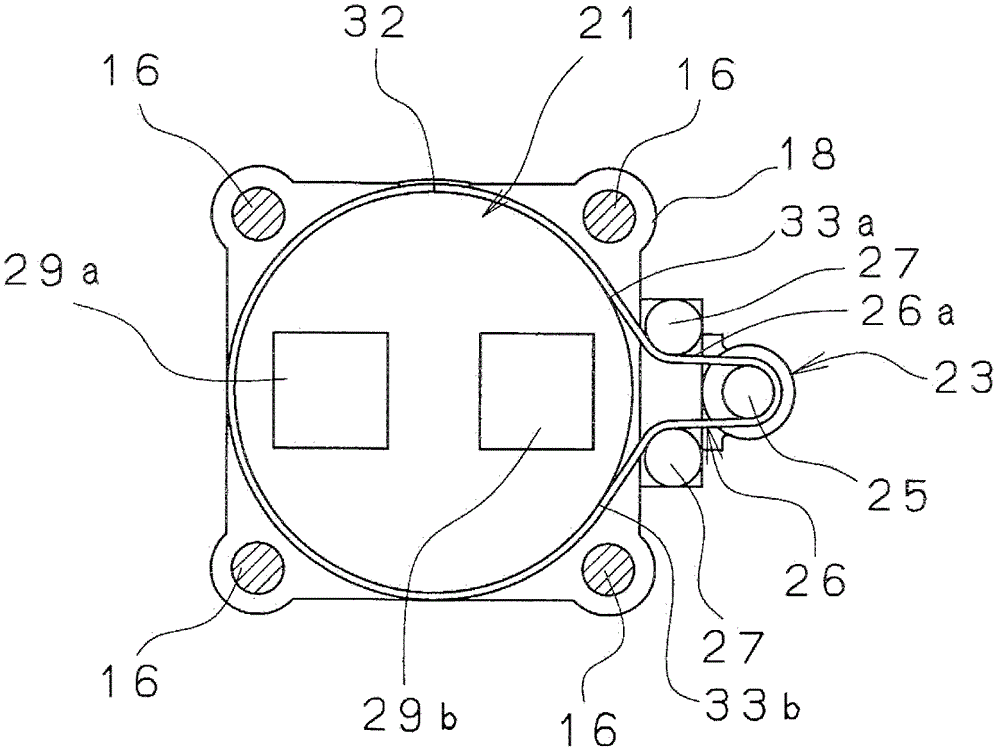

[0020] refer to Figure 1 ~ Figure 3 A mold rotary injection molding machine 11 according to an embodiment of the present invention will be described. A mold rotary injection molding machine 11 , which is a type of injection molding machine, basically includes a mold clamping device 12 , and a first injection device 13 and a second injection device 14 provided on both sides thereof. The clamping device 12 fixes four connecting rods 16 in the upright direction on the fixed disk 15 arranged below, and an upper disk 17 is fixed above the connecting rods 16 . In addition, the connecting rods 16 are inserted around the four corners of the movable platen 18 , and the movable platen 18 can move in the vertical direction between the fixed platen 15 and the upper plate 17 . In addition, a mold clamping cylinder 19 is provided on the upper plate 17 , and the piston 20 of the mold clamping cylinder 19 is fixed on the back surface of the movable plate 18 . In addition, an unillustrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com