Chain guide

A guide and chain technology, applied in belts/chains/gears, engine components, valve devices, etc., can solve the problems of loose installation state of chain guides, screw penetration holes and loose mounting screws, etc. Ease of use and the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, the chain guide 10 which concerns on 1st Embodiment of this invention is demonstrated based on drawing.

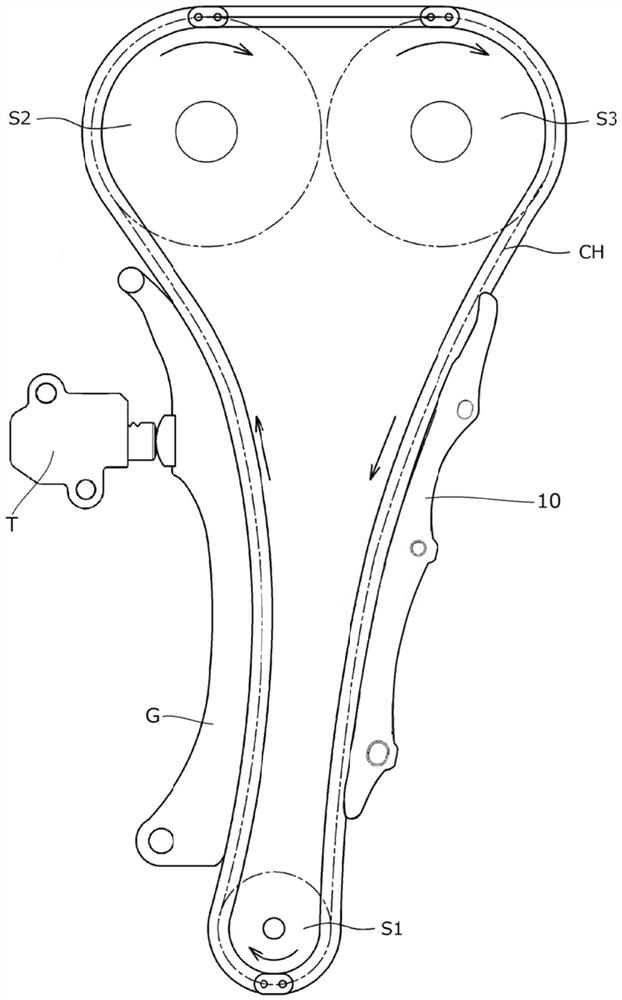

[0040] like figure 1 and Figure 8 As shown, the chain guide 10 according to the first embodiment of the present invention is used by being incorporated into a timing system installed in an engine room, and is fixed to an engine block E as an installation object by an installation screw B, so that the The chain CH is slidably guided, and the chain CH is wound between the sprockets S1 to 3 respectively provided on the crankshaft and the camshaft. In addition, in figure 1 In the timing system shown, in addition to the chain guide 10, as a guide for slidingly guiding the moving chain CH, a rocking guide G is provided, and the rocking guide G is pivotally supported in the engine compartment so as to be rockable, And it is pressed toward the chain CH side by the tensioner T.

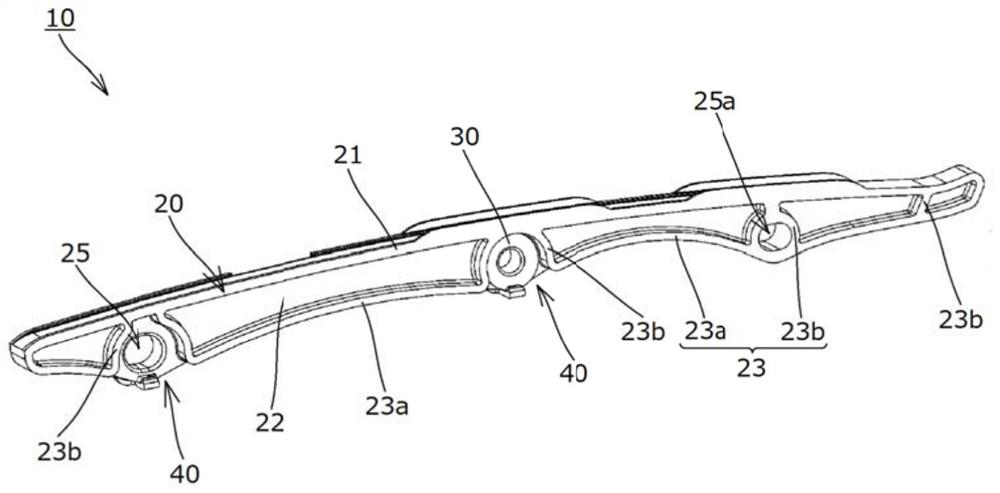

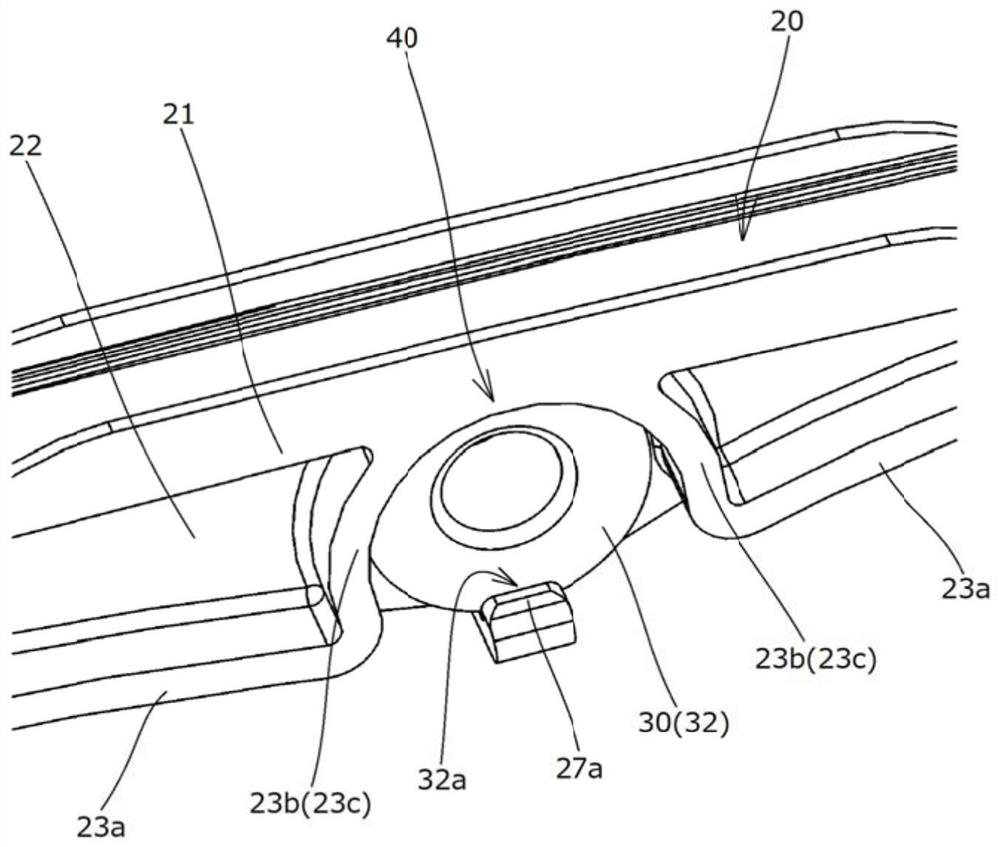

[0041] like figure 2 and image 3 As shown, the chain guide 10 includes a guide body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com