Method for manufacturing work piece by vacuum assisted resin transfer moulding

A resin transfer molding, vacuum-assisted technology for consistent resin distribution in sustainable manufacturing/processing, end product manufacturing, household components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

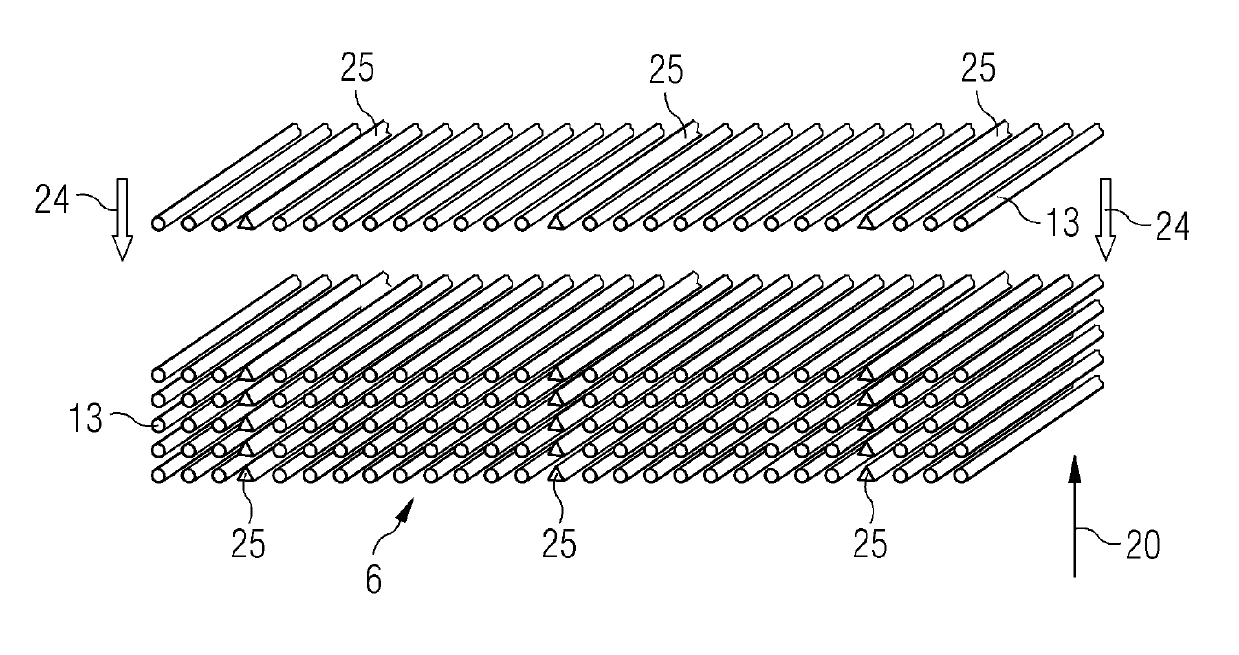

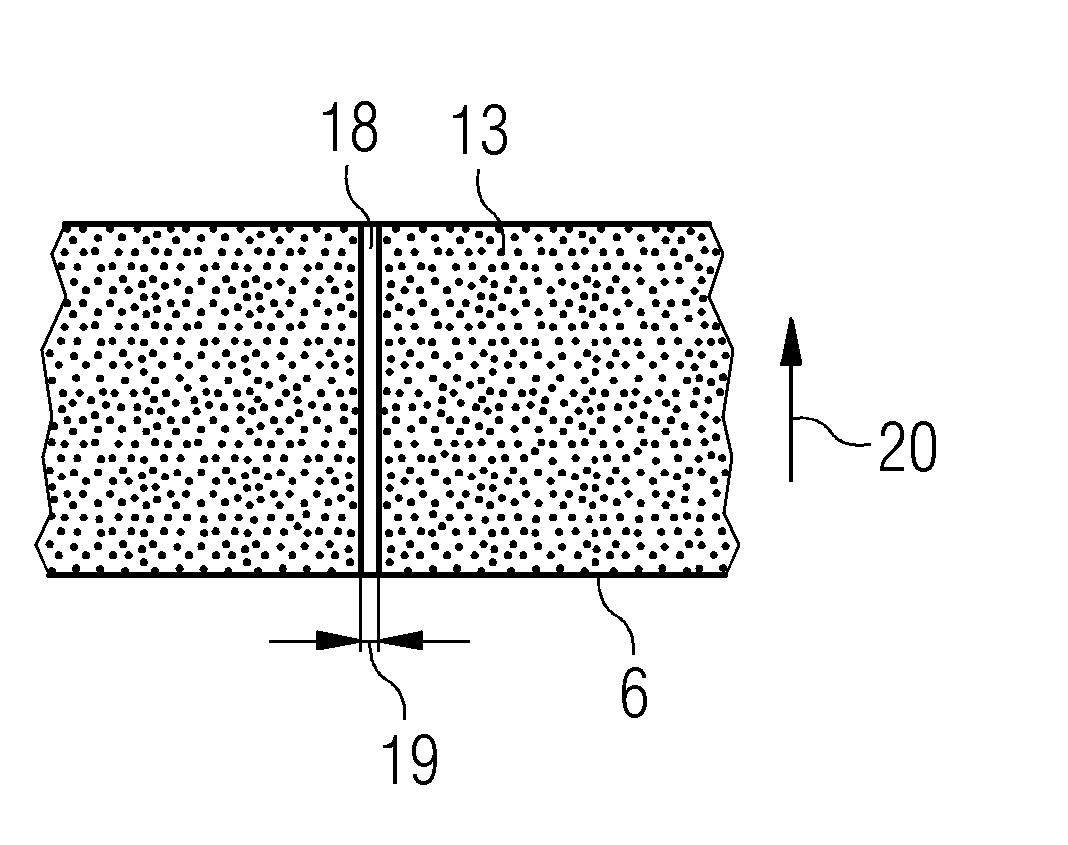

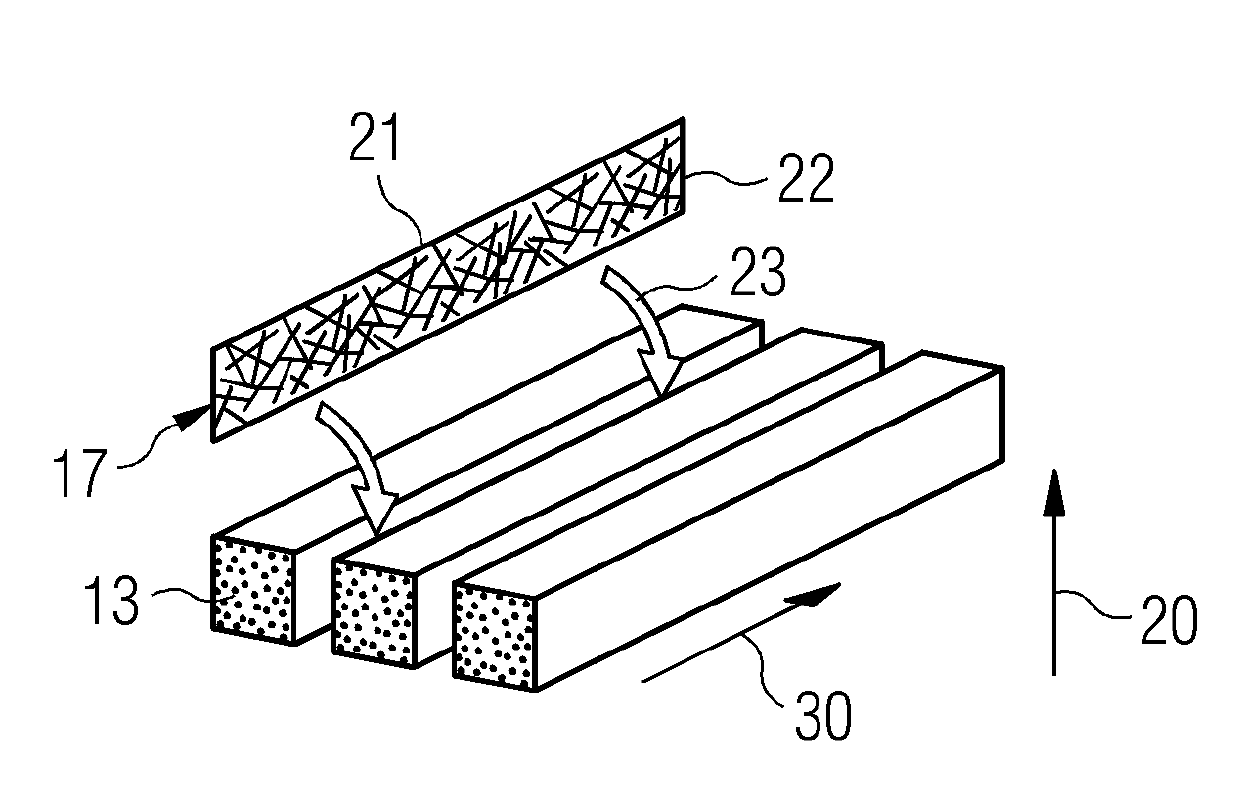

[0033] will now refer to Figure 1 to Figure 9 Embodiments of the present invention are described.

[0034] figure 1 The rotor blade is diagrammatically shown in plan view on the plane defined by the blade span and the blade chord. The spanwise direction is indicated by reference numeral 30 . figure 1 The rotor blade 1 shown in includes a root portion 3 with a cylindrical profile and a tip 2 . The tip forms the outermost part of the blade. The cylindrical profile of the root part 3 is used to fix the blade to the bearing of the rotor hub. The rotor blade 1 also comprises a so-called shoulder 4 defined as the location of its maximum profile depth, ie the maximum chord length of the blade. An airfoil portion 5 extends between the shoulder 4 and the tip 2, which has an aerodynamic profile. A transition section 7 extends between the shoulder 4 and the cylindrical root section 3 , wherein a transition from the aerodynamic profile of the airfoil section 5 to the cylindrical pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap