High-strength impeller

A high-strength, impeller technology, applied to the components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as blade breakage and shorten the service life of impellers, and achieve not easy to break, The effect of increasing the service life and reducing the transmission pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

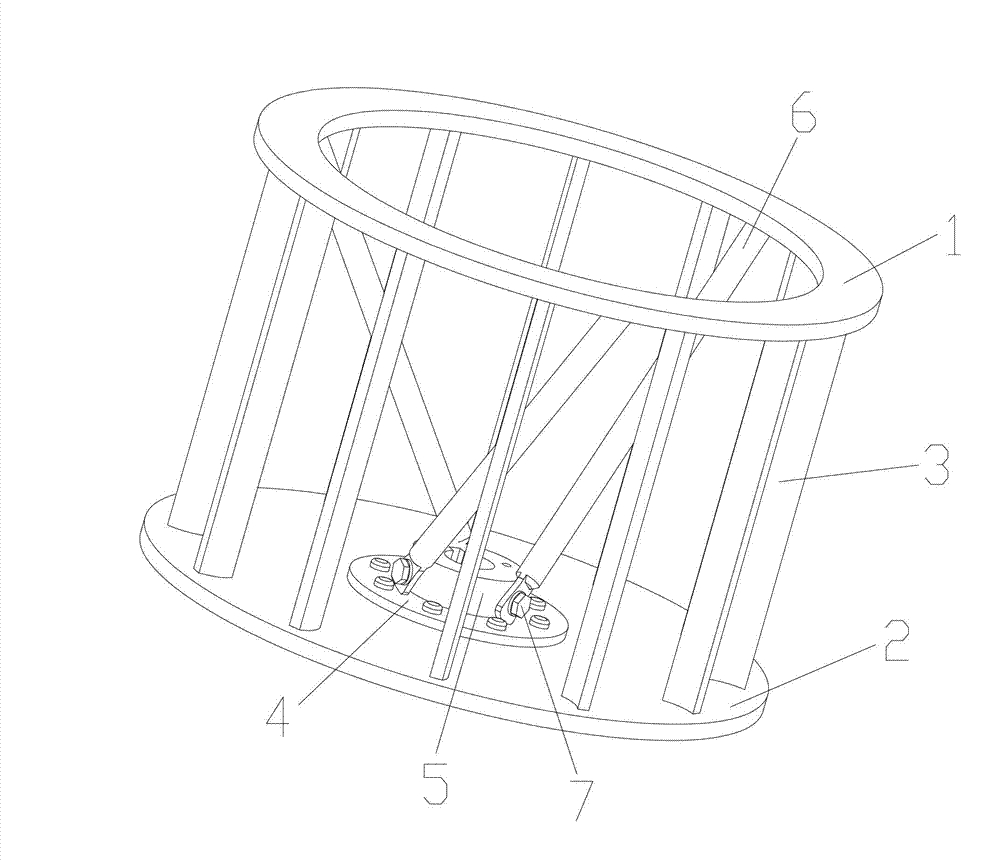

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 The shown high-strength impeller of the present invention includes a front cover 1, a rear cover 2 and blades 3, and there are multiple blades 3 in an annular array between the front cover 1 and the rear cover 2, so The inner surface of the rear cover 2 is provided with a connection plate 4; the center of the connection plate 4 is provided with a pivot 5, and at least two reinforcing ribs 6 are connected between the front cover 1 and the rear cover 2; One end of the reinforcing rib 6 is welded to the front cover 1 , and the other end is fixed on the side surface of the pivot 7 through the pin 7 .

[0014] During the rotation process of a high-strength impeller according to the present invention, the blade 3 and the pivot 5 are driven by the back cover 2 to rotate, so that the blade 3 and the rib 6 fixed on the side surface of the pivot 7 drive the front Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com