Steam cleaning machine

A washing machine and steam technology, used in cleaning machinery, carpet cleaning, floor cleaning, etc., can solve problems such as dry burning or overflowing, inability to accurately control the heating body, and cumbersome use, to prevent dry burning or overflowing, Achieve the effect of automating design, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

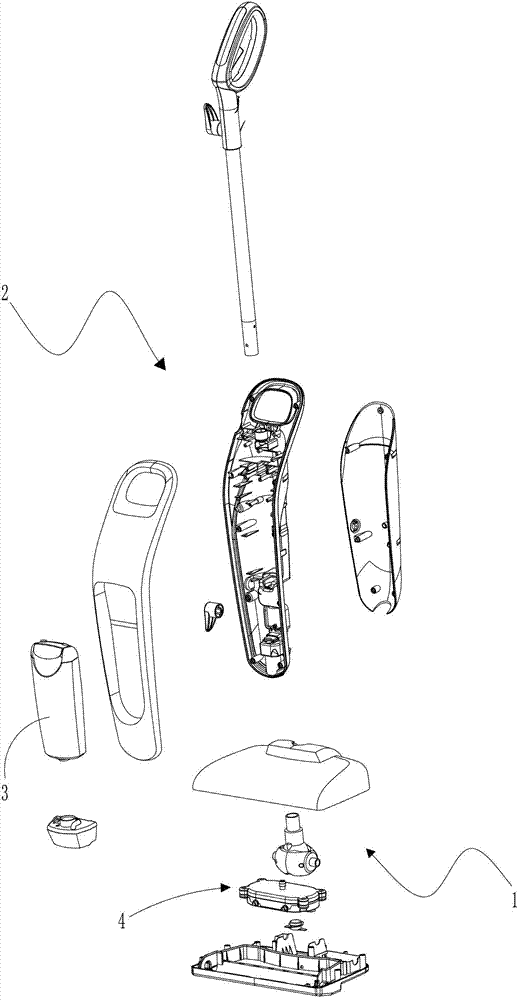

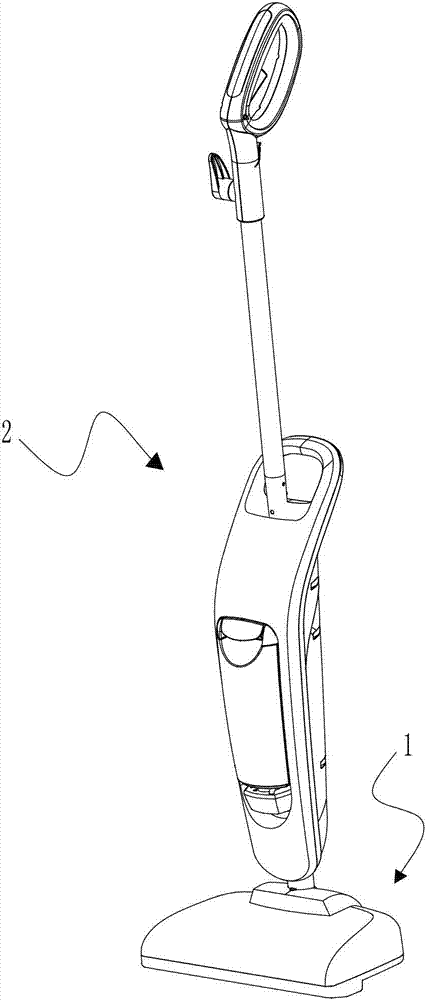

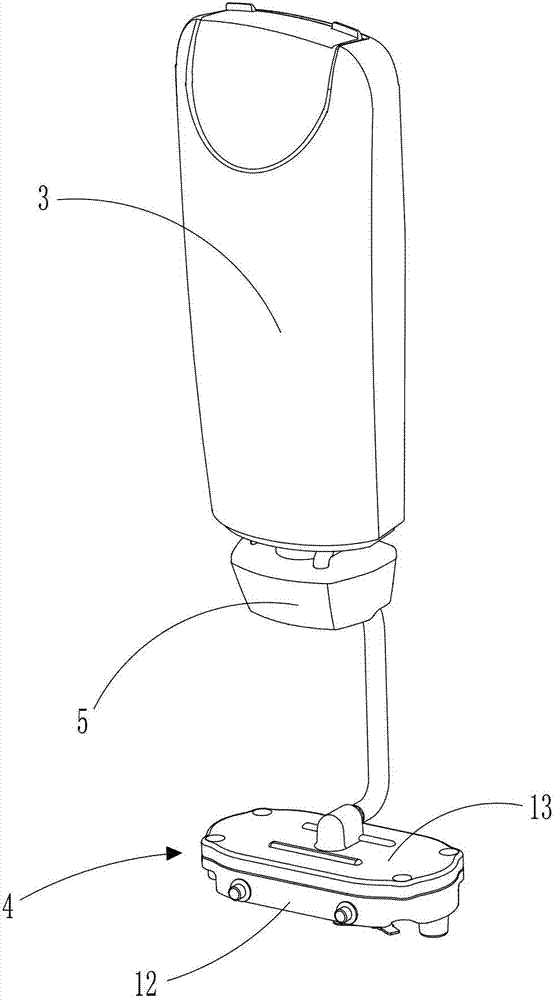

[0017] as attached figure 1 to attach Figure 4 As shown, the steam cleaning machine of the present invention includes a cleaning brush head 1 for cleaning the surface to be cleaned, a handle assembly 2 arranged on the top of the cleaning brush head 1, a steam supply mechanism that provides steam to the cleaning brush head 1, and the steam supply mechanism Including the water tank 3 arranged in the handle assembly 2, the heater 4 arranged in the cleaning brush head 1, the water supply controller 5 connected between the water outlet of the water tank 3 and the water inlet of the heater 4, the water supply controller 5 has The water injection port 6 and the water collection chamber connected with the inside of the water tank 3, the water injection port 6 is formed by extending downward from the water tank 3, the water collection ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com