Hanging-type irrigation shower nozzle

A hanging and sprinkler technology, applied in the field of hanging irrigation sprinklers, can solve the problems of irrigation blind spots, increase facility input and irrigation costs, affect the scope and area of irrigation, and achieve uniform spraying, reduce investment and irrigation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

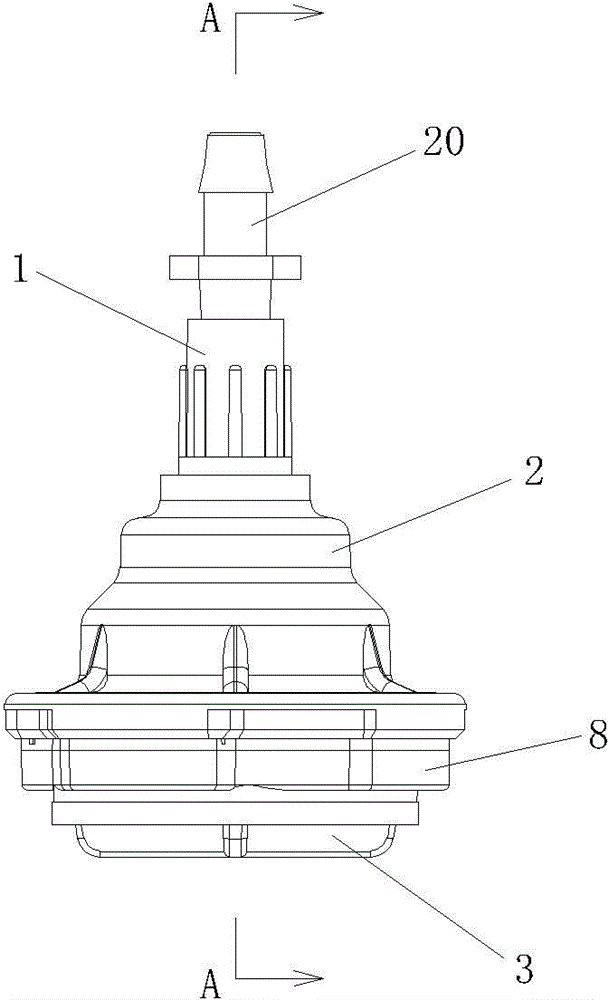

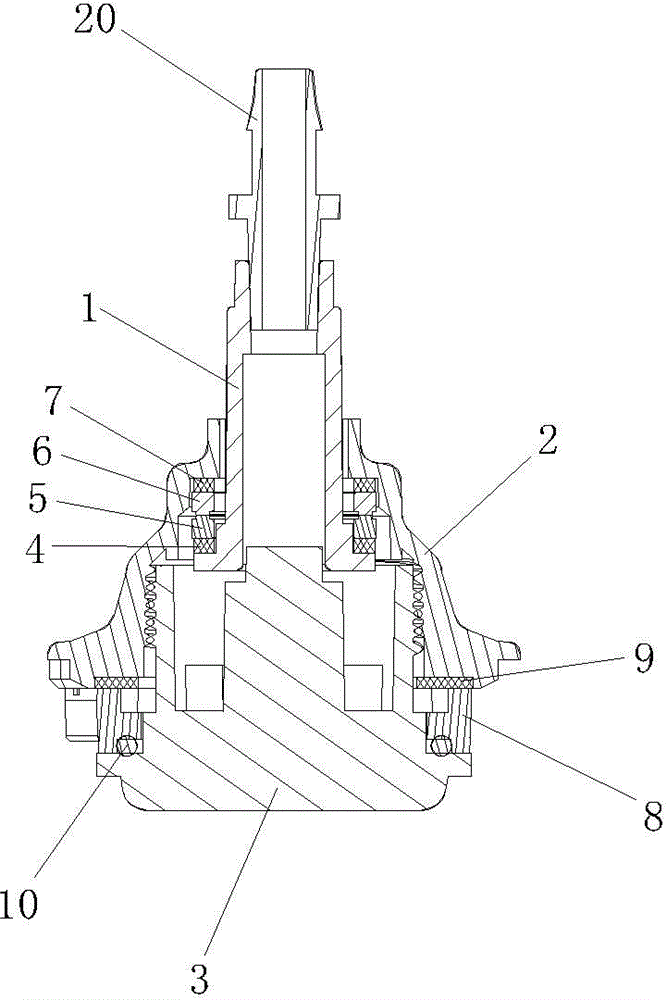

[0025] Embodiment one, Figure 1 to Figure 9 As shown, a hanging irrigation nozzle includes a vertically suspended water inlet pipe 1, an upper housing 2, and a lower housing 3. The lower part of the upper housing 2 is provided with an internal thread 21, and the upper part of the lower housing 3 is provided with External thread 31, the lower part of the upper casing 2 and the upper part of the lower casing 3 are locked by the internal thread 21 and the external thread 31, the lower end of the water inlet pipe 1 is provided with an annular flange 11, and the middle of the upper casing 2 There is a stepped installation hole 22 with a small top and a large bottom. The lower part of the water inlet pipe 1 passes through the stepped installation hole 22 of the upper casing 2. The first rubber gasket 4, the first ceramic rotating ring 5, the second ceramic rotating ring 6, and the second rubber sealing gasket 7 are sequentially installed between the lower end surfaces 221 of the la...

Embodiment 2

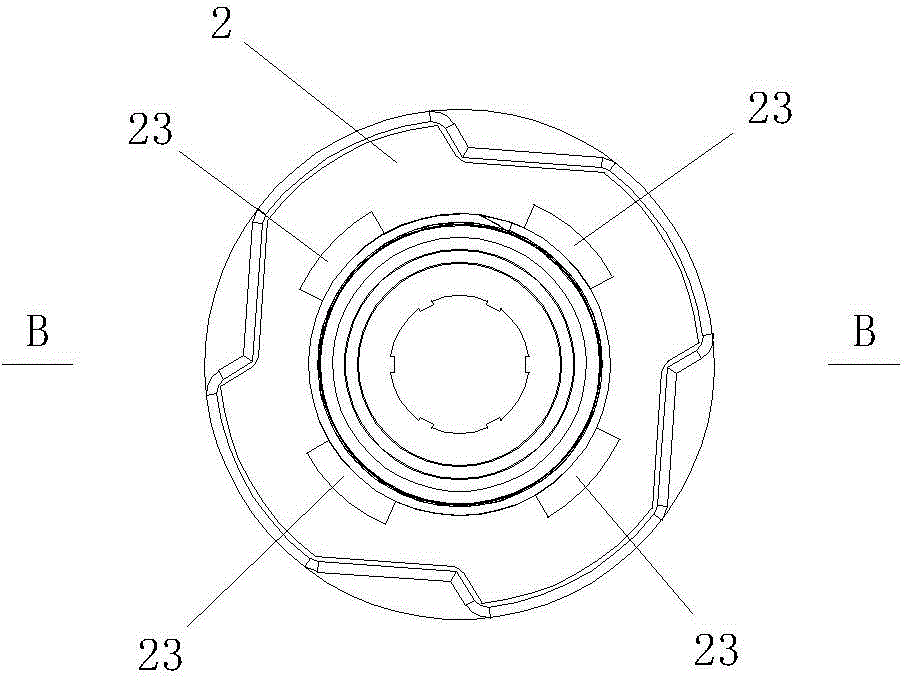

[0031] Embodiment two, combine Figure 10 As shown, it differs from the first embodiment in that the structure of the water outlet groove and the water outlet hole of the water outlet ring 8 is different, and each water outlet end surface 81 on the water outlet ring 8 is provided with three tangential water outlet holes 814, and three tangential water outlet holes 814 are provided. The water outlet hole 814 is connected to the water outlet channel 33 on the outer peripheral surface of the lower casing 3 through a water outlet groove 815 provided on the water outlet ring 8 .

[0032] The working principle of the second embodiment is basically the same as that of the first embodiment. The difference is that the water flows through the water outlet channel 33 on the outer peripheral surface of the lower casing 3, passes through a water outlet groove 815 on the water outlet ring 8, and sprays from three tangential water outlet holes 811 at the same time. out, forming three thin li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com