Automotive engine gas nozzle mounting bracket

A technology for automobile engines and gas nozzles, which is applied in the direction of engine components, machines/engines, fuel injection devices, etc., and can solve the problems of small contact area between bracket and cylinder head cover, fracture of back plate and lower vertical plate, poor stability of nozzle support, etc. , to achieve the effect of being conducive to mass production, reliable connection and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

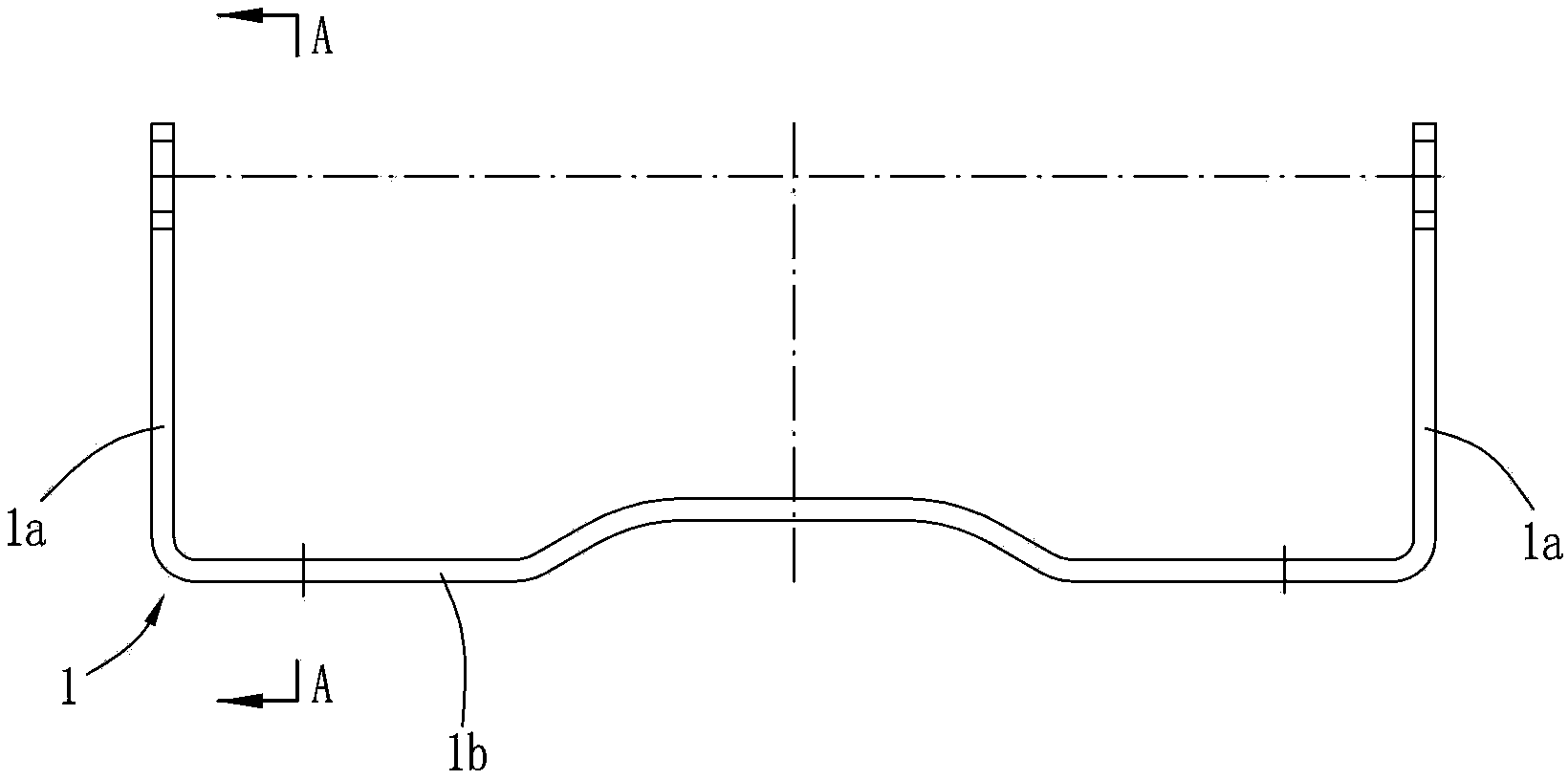

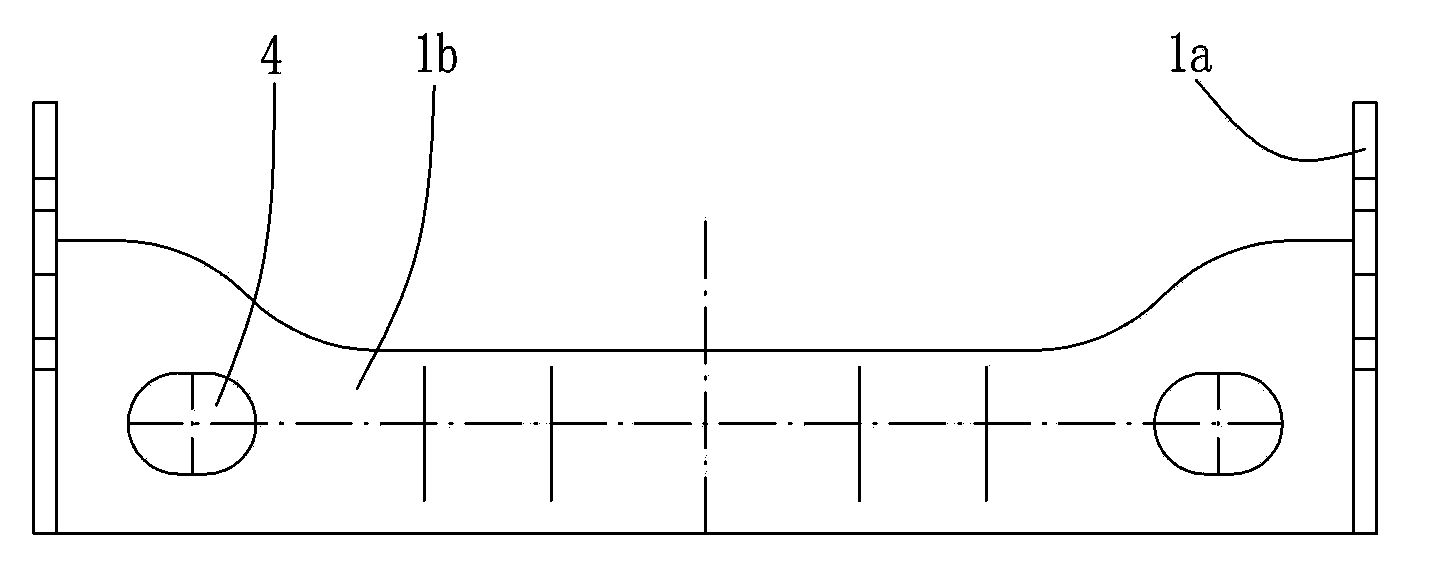

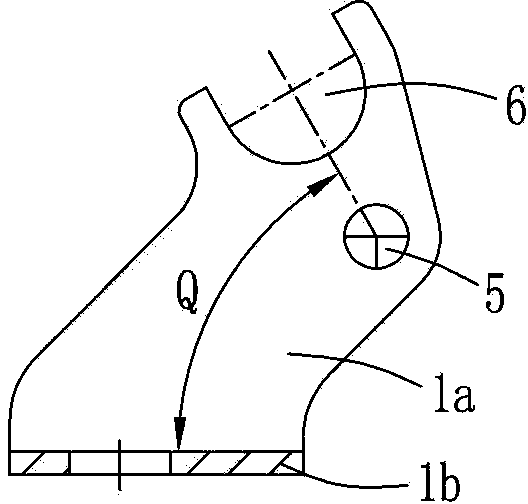

[0022] like figure 1 , figure 2 and image 3 As shown, the nozzle bracket of an automobile engine has a frame body 1, which is formed by stamping a plate, and is composed of side plates 1a symmetrically arranged on the left and right sides and a bottom plate 1b at the bottom. The side plate 1a is perpendicular to the bottom plate 1b, and the side plate 1a The bottom of the bottom is connected with the end of the bottom plate 1b. The middle part of the bottom plate 1b is deformed and arched upwards to increase the structural strength of the bottom plate 1b and prevent the bottom plate 1b from being deformed. There are two left-right symmetrical bracket installation holes 4 on the base plate 1b. These two bracket installation holes 4 are separated on both sides of the arched part in the middle of the base plate 1b, and each bracket installation hole 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com