A current sampling circuit for intelligent power module

An intelligent power module and current sampling technology, which is applied in the direction of output power conversion device, AC power input conversion to DC power output, emergency protection circuit device, etc., can solve the problem of intelligent power module damage, failure of intelligent power module overcurrent protection, Explosion and other problems to achieve the effect of reducing the probability of explosion, eliminating fire hazards, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

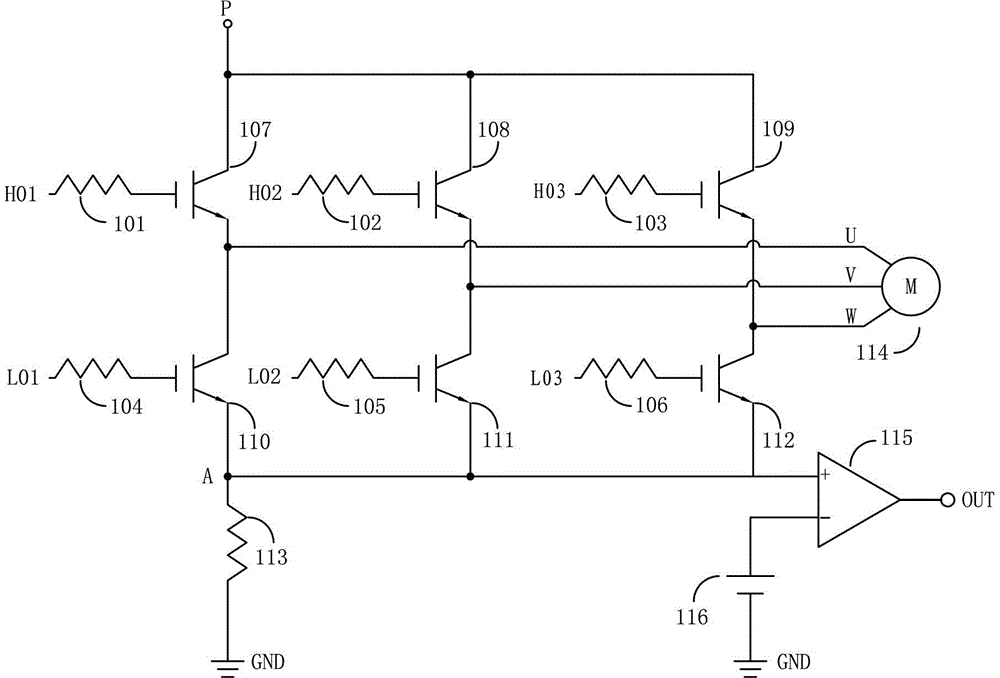

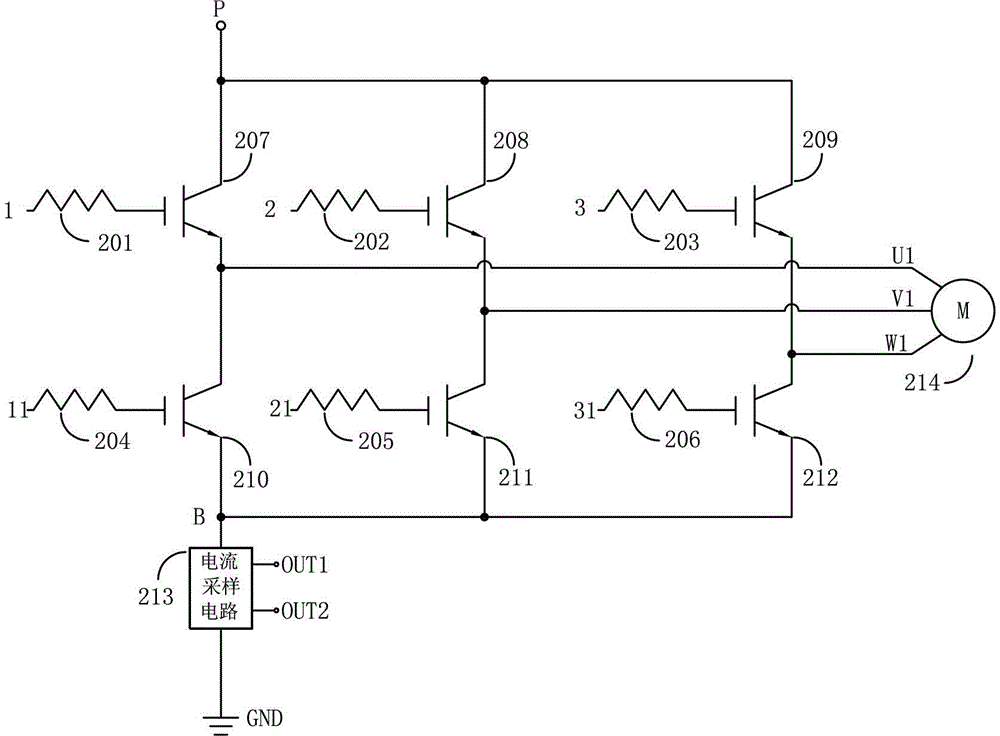

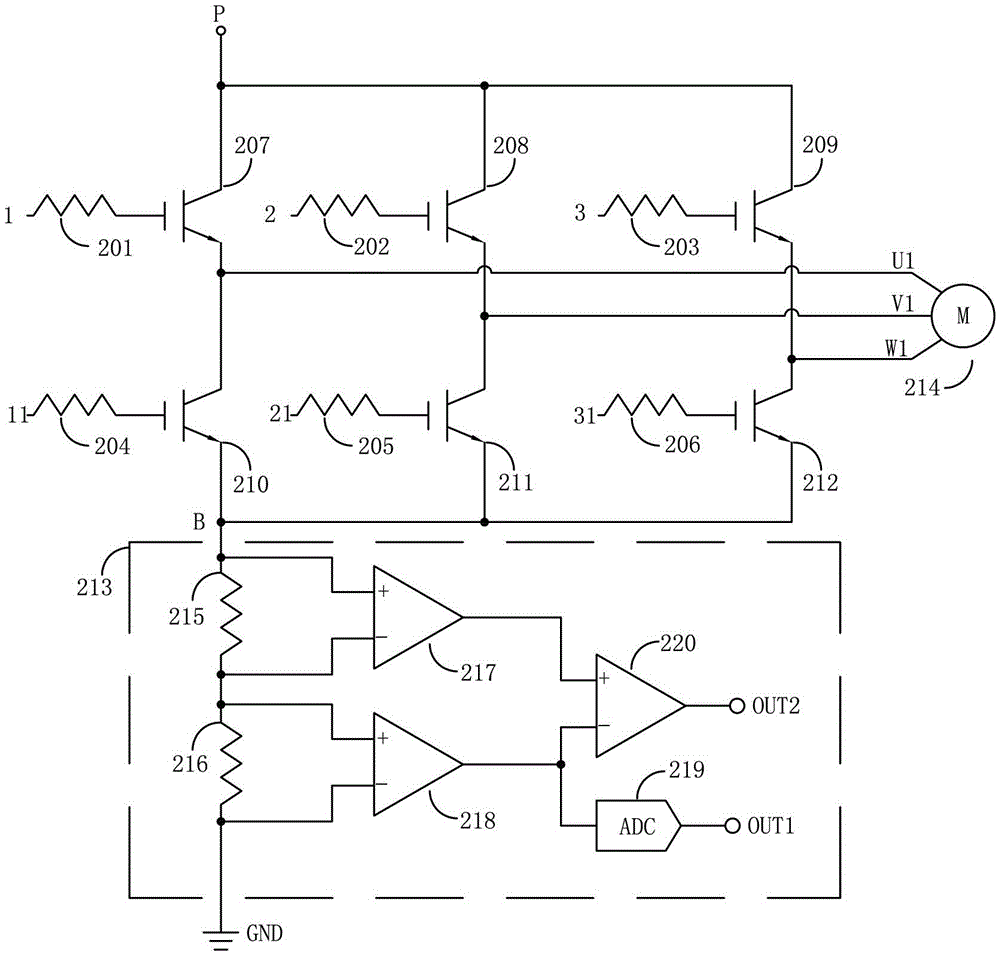

[0020] see Figure 2-Figure 3 , a current sampling circuit for an intelligent power module, including a first upper bridge arm 1, a second upper bridge arm 2, and a third upper bridge arm 3, and a first lower bridge arm 11 set corresponding to each upper bridge arm, The second lower bridge arm 21 and the third lower bridge arm 31, the upper and lower bridge arms are respectively connected to the gate of the corresponding IGBT tube through resistors, corresponding to the first upper resistor 201, the second upper resistor 202, and the third upper resistor 203 , the first lower resistor 204, the second lower resistor 205 and the third lower resistor 206; the collector phases of the IGBT tubes on each upper bridge arm are connected to the high voltage point P, and the collector phases of the IGBT tubes on each lower bridge arm are connected to the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com