Electroconductive endless belt

A conductive, endless belt technology, applied in the direction of electrorecording, electrorecording process applying charge pattern, and equipment applying charge pattern electrorecording process, etc. Cost, uniform effect without local deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0146] (Examples 1-9, Comparative Examples 1-6)

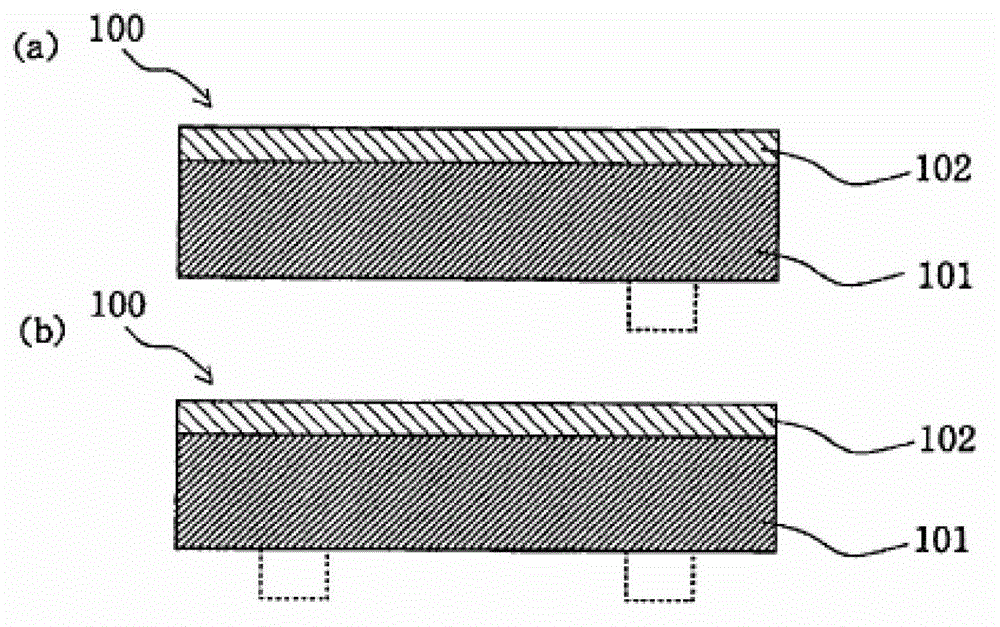

[0147] The conductive endless belts of the respective examples and comparative examples were produced according to the formulations shown in each of the following Tables 6 to 8. Specifically, by using a twin-screw kneader to melt and knead each of the compounding components with a base shown in each table, and extrude the obtained kneaded product using a ring die, a product having an inner diameter of 220 mm was obtained. , the base layer 101 having a thickness of 100 μm and a width of 250 mm. Then, on the base layer 101, a solvent coating solution of a resin layer prepared using the compounding materials shown in the tables and using methyl ethyl ketone as a solvent was spray-coated so that the film thickness after drying was 2 μm. While rotating the coated tape 100, using a UNICURE UVH-0252C device manufactured by Ushio Inc., with an illuminance of 400 mW and a cumulative light intensity of 1000 mJ / cm 2 Under certain condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com