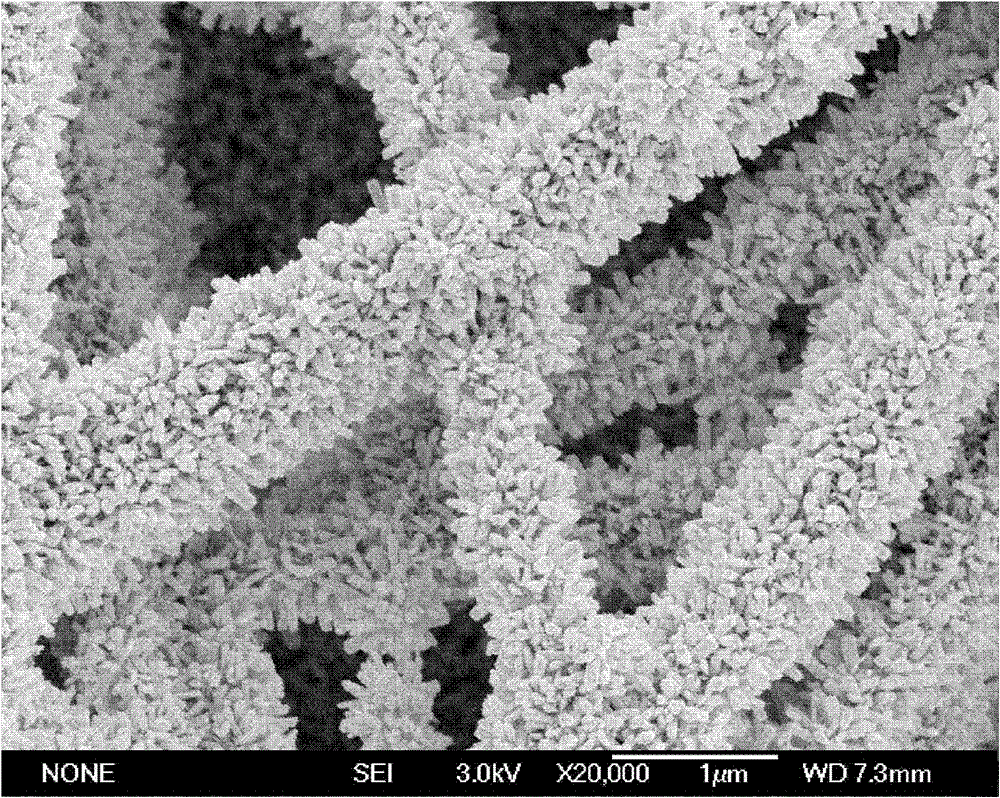

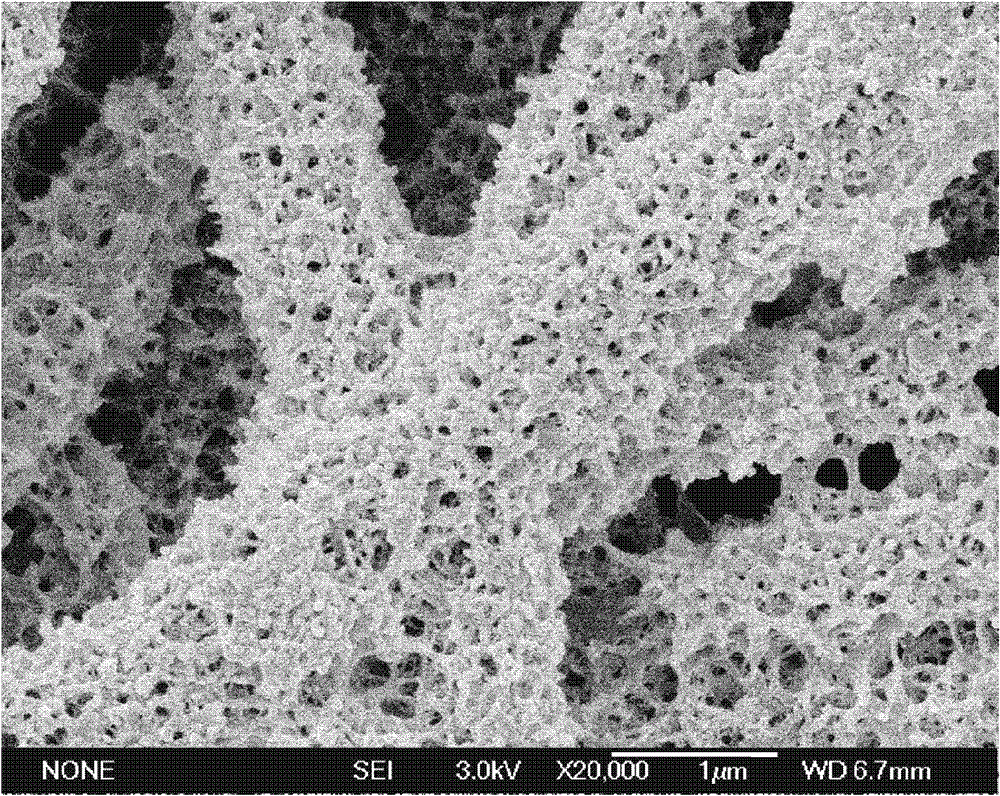

Underwater self-cleaning superoleophobic mineralized fibrous film and preparation method thereof

A fiber membrane and super-oleophobic technology, applied in chemical instruments and methods, fiber treatment, separation methods, etc., to achieve stable oleophobic performance, diverse raw materials, economical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) cellulose acetate is dissolved in a mixed solvent of N, N-dimethylacetamide and acetone to obtain a cellulose acetate solution, wherein the mass fraction of cellulose acetate is 12%, N, N - The volume ratio of dimethylacetamide to acetone is 1:2; add sodium polybenzenesulfonate whose mass is 6% of the mass of cellulose acetate solution as a mineralization regulator, and stir to make it uniformly dispersed in cellulose acetate In the ester solution, a mixed spinning solution is obtained; wherein the mass ratio of sodium polybenzenesulfonate to cellulose acetate is 1:2.

[0051] 2) Put the mixed spinning solution containing cellulose acetate and sodium polybenzenesulfonate obtained in step 1) into a syringe, connect the syringe to a syringe pump, and adjust the flow rate of the mixed spinning solution to 0.5ml / h. A grounded aluminum foil is placed 20cm away from the needle of the syringe, and a 20kV high-voltage electrostatic field is applied between the needle of the ...

Embodiment 2

[0055] 1) cellulose acetate butyrate is dissolved in a mixed solvent of acetic acid and acetone to obtain a cellulose acetate butyrate solution, wherein the mass fraction of cellulose acetate butyrate is 50%, and the volume ratio of acetic acid to acetone is 1 : 1; Adding sodium polybenzenesulfonate with a quality of 10% of the cellulose acetate butyrate solution quality as a mineralization regulator, making it evenly dispersed in the cellulose acetate butyrate solution through stirring, to obtain a mixed spinning solution; Wherein the mass ratio of sodium polybenzenesulfonate to cellulose acetate butyrate is 1:5.

[0056] 2) Put the mixed spinning solution containing cellulose acetate butyrate and sodium polybenzenesulfonate obtained in step 1) into a syringe, connect the syringe to a syringe pump, and adjust the flow rate of the mixed spinning solution to 0.5ml / h. A grounded aluminum foil is placed 20cm away from the needle of the syringe, and a 20kV high-voltage electrostat...

Embodiment 3

[0060]1) dissolving cellulose phthalate in a mixed solvent of ethanol and dichloromethane to obtain a cellulose phthalate solution, wherein the mass fraction of cellulose phthalate is 6%, The volume ratio of ethanol to methylene chloride is 1:1; sodium dodecylbenzenesulfonate with a mass of 0.1% of the mass of cellulose phthalate solution is added as a mineralization regulator, and it is uniformly dispersed in the In the cellulose phthalate solution, a mixed spinning solution is obtained; wherein the mass ratio of sodium dodecylbenzenesulfonate to cellulose phthalate is 1:60.

[0061] 2) the mixed spinning solution containing cellulose phthalate and sodium dodecylbenzenesulfonate obtained in step 1) is placed in the syringe, and the syringe is connected to the syringe pump, and the flow velocity of the mixed spinning solution is adjusted to 0.5ml / h. A grounded aluminum foil is placed 20cm away from the needle of the syringe, and a 20kV high-voltage electrostatic field is appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com