Preparation method of super-amphiphobic paint for wood-plastic composite material surface

A wood-plastic composite material and super-amphiphobic technology, applied in the coating and other directions, can solve the problems of acid-base aging of oil stains, water absorption deformation, etc., and achieve the effects of good acid resistance, low water absorption, and stable oleophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

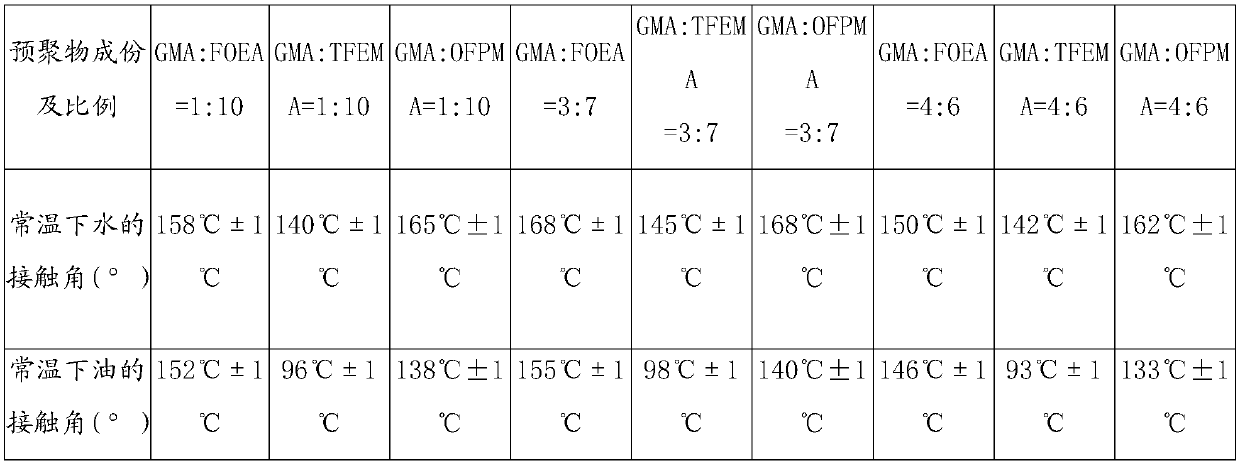

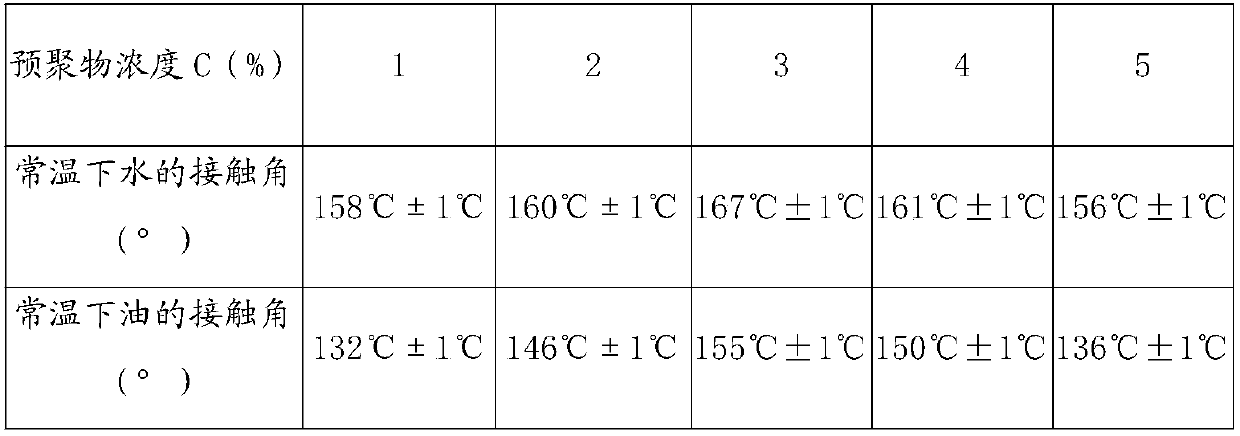

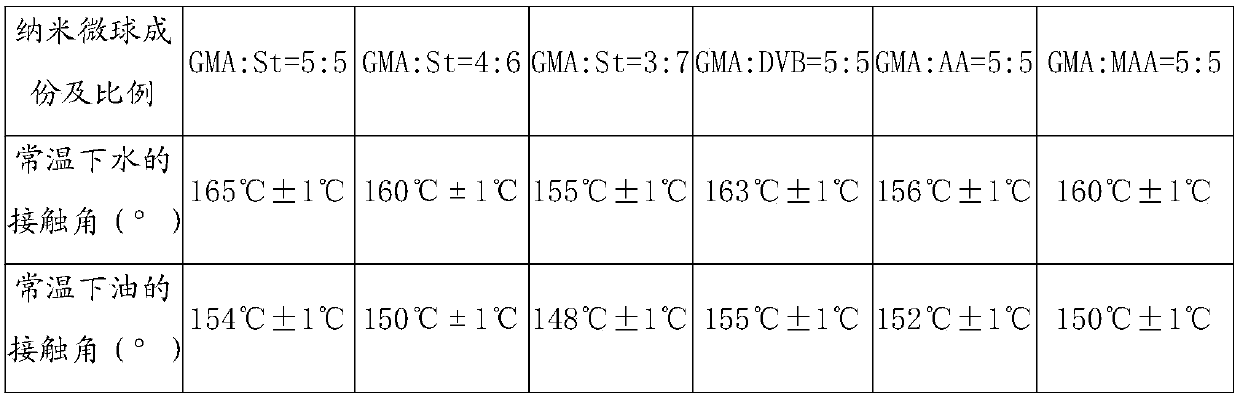

[0020] The mass ratios of glycidyl methacrylate (GMA) and heptadecanyl fluorodecyl methacrylate (FOEA) were weighed respectively to be 3g and 0.3g, azobisisobutyronitrile and sodium bisulfite to be 67mg and 42mg; All the reagents weighed were added to the reaction vessel, and 5ml of trifluorotoluene was added to the vessel. Seal the container and pass nitrogen gas for 30 minutes to remove the oxygen in the container; place the reaction container in a collector type magnetic stirrer and heat it for 60 minutes to make the reaction monomer in the reaction container fully react with the initiator and catalyst to produce a prepolymer After the reaction, the product was taken out; the prepolymer was added dropwise to the n-hexane vortex, and the flocculent precipitate was formed, the n-hexane was filtered, and the solvent was volatilized to obtain a pure prepolymer (PGMA-r-PFOEA).

[0021] Weigh the initiator azobisisobutyronitrile, catalyst NaHSO 3 The amount of each 0.1g, emulsif...

Embodiment 2

[0067] The mass ratios of glycidyl methacrylate (GMA) and heptadecanyl fluorodecyl methacrylate (FOEA) were weighed respectively to be 3g and 1.29g, azobisisobutyronitrile and sodium bisulfite to be 67mg and 42mg; All the reagents weighed were added to the reaction vessel, and 5ml of trifluorotoluene was added to the vessel. Seal the container and feed nitrogen gas for 45 minutes to remove the oxygen in the container; place the reaction container in a heat-collecting magnetic stirrer and heat it for 45 minutes to fully react the reaction monomer in the reaction container with the initiator and catalyst to produce a prepolymer After the reaction, the product was taken out; the prepolymer was added dropwise to the n-hexane vortex, and the flocculent precipitate was formed, the n-hexane was filtered, and the solvent was volatilized to obtain a pure prepolymer (PGMA-r-PFOEA).

[0068] Weigh respectively initiator azobisisobutyronitrile, catalyst NaHSO The amount is each 0.1g, emul...

Embodiment 3

[0072] The mass ratios of glycidyl methacrylate (GMA) and heptadecanyl fluorodecyl methacrylate (FOEA) were weighed respectively to be 3g and 0.3g, azobisisobutyronitrile and sodium bisulfite to be 67mg and 42mg; All the reagents weighed were added to the reaction vessel, and 5ml of trifluorotoluene was added to the vessel. Seal the container and feed nitrogen gas for 36 minutes to remove the oxygen in the container; place the reaction container in a heat-collecting magnetic stirrer and heat it for 36 minutes, so that the reaction monomer in the reaction container can fully react with the initiator and catalyst to produce a prepolymer After the reaction, the product was taken out; the prepolymer was added dropwise to the n-hexane vortex, and the flocculent precipitate was formed, the n-hexane was filtered, and the solvent was volatilized to obtain a pure prepolymer (PGMA-r-PFOEA).

[0073] Weigh respectively initiator azobisisobutyronitrile, catalyst NaHSO The amount is each 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com