Connection method and structure for inner battery box and outer battery box

A connection method and connection structure technology, which is applied in the field of battery box replacement, can solve the problems of connection components burning, unfavorable standardization and installation, and connector detachment, so as to improve production and installation efficiency, wide versatility and interchangeability, Ease of production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

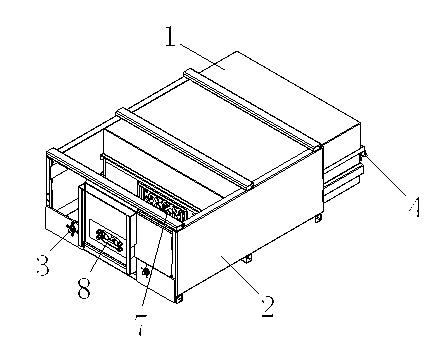

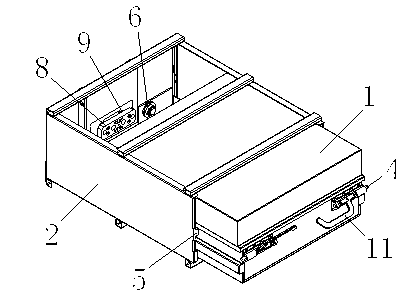

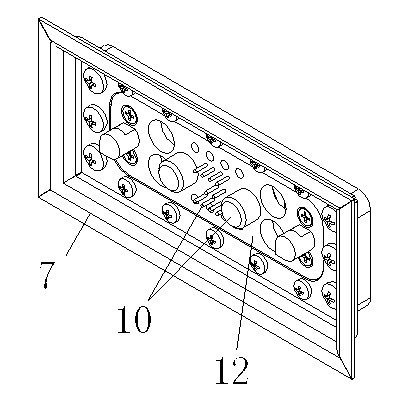

[0026] Embodiments of the present invention: the principle of the connection method of a battery inner and outer box of the present invention is as follows, as figure 1 and figure 2 As shown, the battery inner box 1 and the battery outer box 2 are connected in a drawer type; the front end of the battery inner box 1 and the battery outer box 2 generate pre-pressure on the battery inner box 1 through the elastic limit seat 3; the battery inner box 1 The locking tongue 4 on the battery outer box 2 is inserted into the lock hole 5; to ensure that the relative position between the battery inner box 1 and the battery outer box 2 does not shift; the bottom of the elastic limit seat 3 is processed with a rigid limit bit station 6 (see figure 2 and Figure 7 ), to prevent excessive extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com