Central spindle for grinding outer edge of shell

A technology of the mandrel and shell, which is applied in the direction of grinding the workpiece support, etc., can solve the problems of inconvenience, shaking of the shell, and insufficient precision in processing the outer edge of the shell, and achieve the effects of saving costs, improving accuracy, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

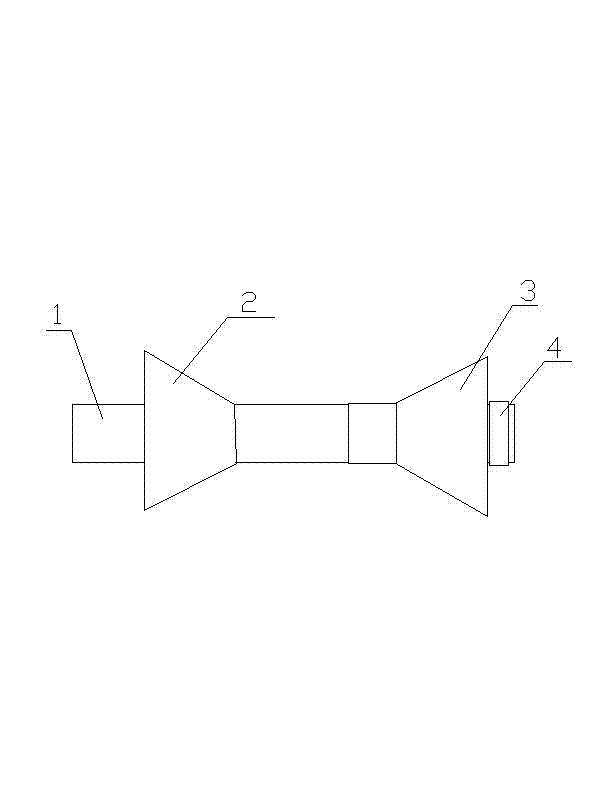

[0014] figure 1 It shows an embodiment of a mandrel for grinding the outer edge of the shell of the present invention, including a mandrel 1, a first positioning cone 2, a second positioning cone 3 and a lock nut 4, the first positioning cone 2 Integral molding is fixed on one end of the mandrel 1, the second positioning cone 3 is sleeved on the other end of the mandrel 1, the lock nut 4 is sleeved on the mandrel 1, the second positioning cone 3 and the small gap between the mandrel 1, when processing the shell, first remove the lock nut 4, then remove the second positioning cone 3, set the shell on the mandrel, and then set the second positionin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap