Process control method for secondary processing of sintered NdFeB in quick-setting furnace

A technology of process control and control method, applied in the field of information, can solve the problems of no research on magnetic materials and cannot be directly applied, and achieve the effects of reducing energy waste, improving remanence, and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

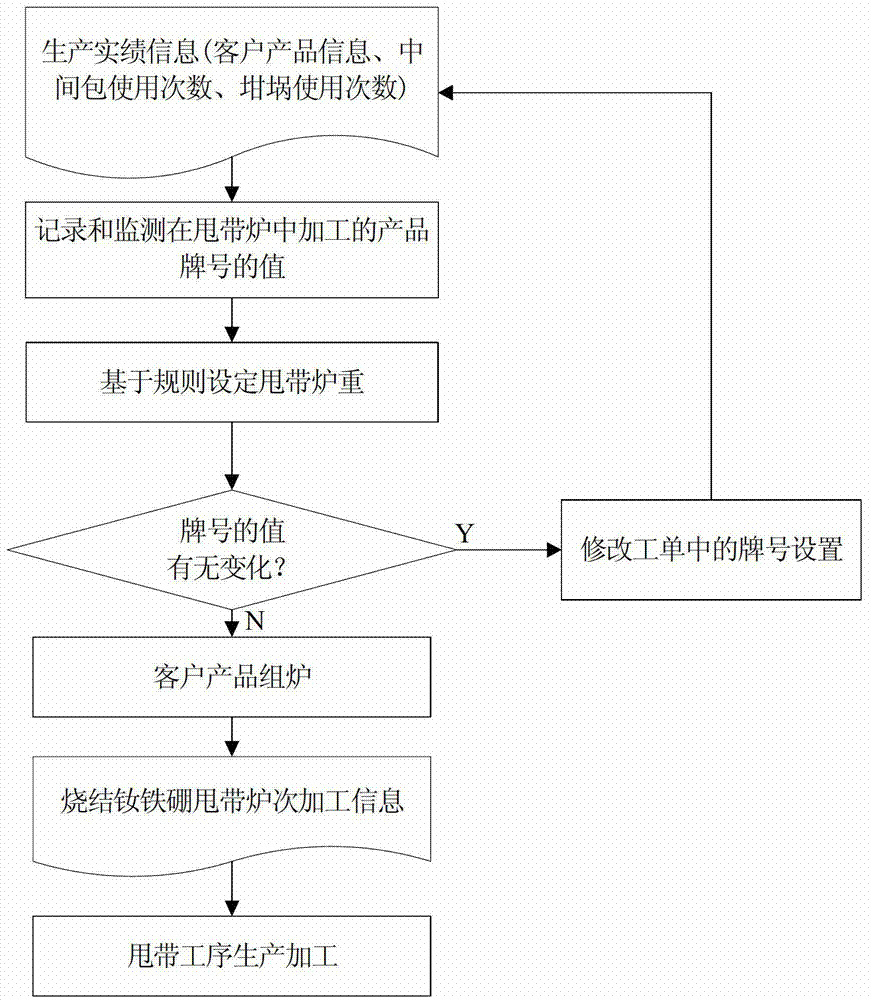

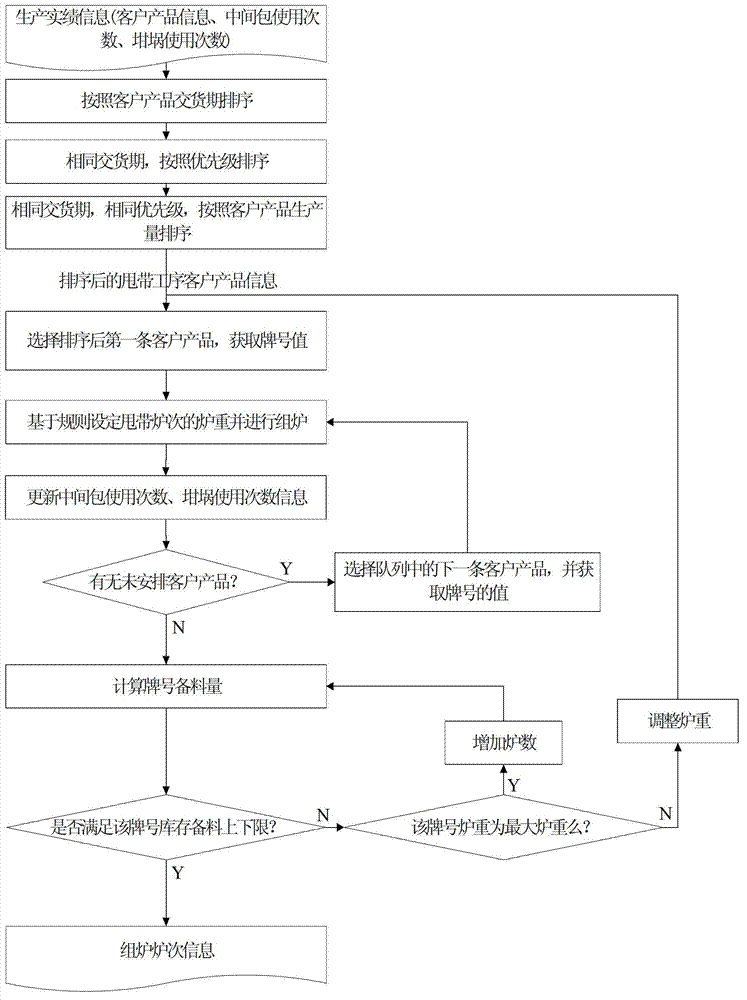

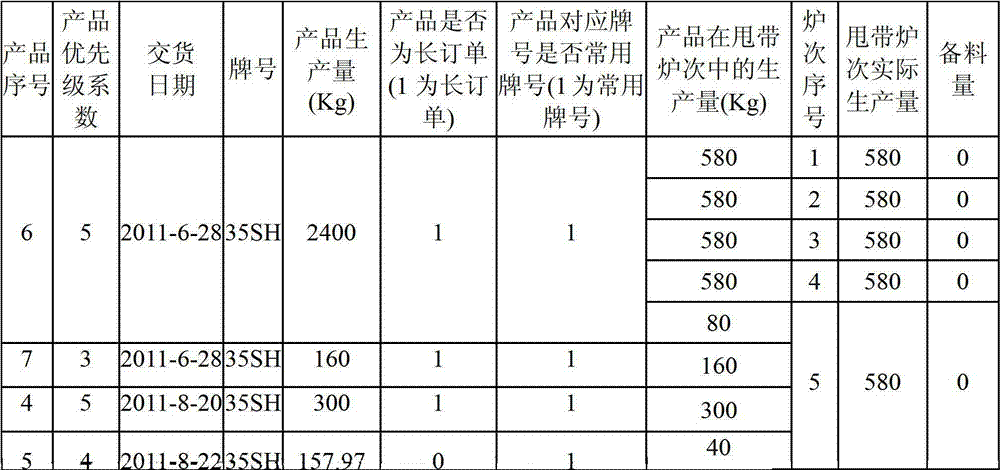

[0025] Take the belt throwing furnace of a certain NdFeB magnetic material enterprise as an example (the project won the National Natural Science Foundation of China (No. 61174187); the Ministry of Education's basic scientific research business fund (No. N110208001); the Northeastern University Startup Fund (No. 29321006) Support), explain the process control method of sintered NdFeB strip furnace processing, the overall process is as follows figure 1 shown. details as follows:

[0026]In this control method, the basic information is set first, involving: the maximum furnace weight of the belt-swing furnace, the minimum furnace weight of the belt-swing furnace, the upper limit of the use times of the crucible in the belt-swing furnace, the upper limit of the use times of the tundish in the belt-swing furnace, and the marking of commonly used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com