A kind of NdFeB magnet material, raw material composition, preparation method and application

A technology of NdFeB and magnets, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve problems such as high cost, and achieve the effects of improving remanence Br, high density, and reducing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

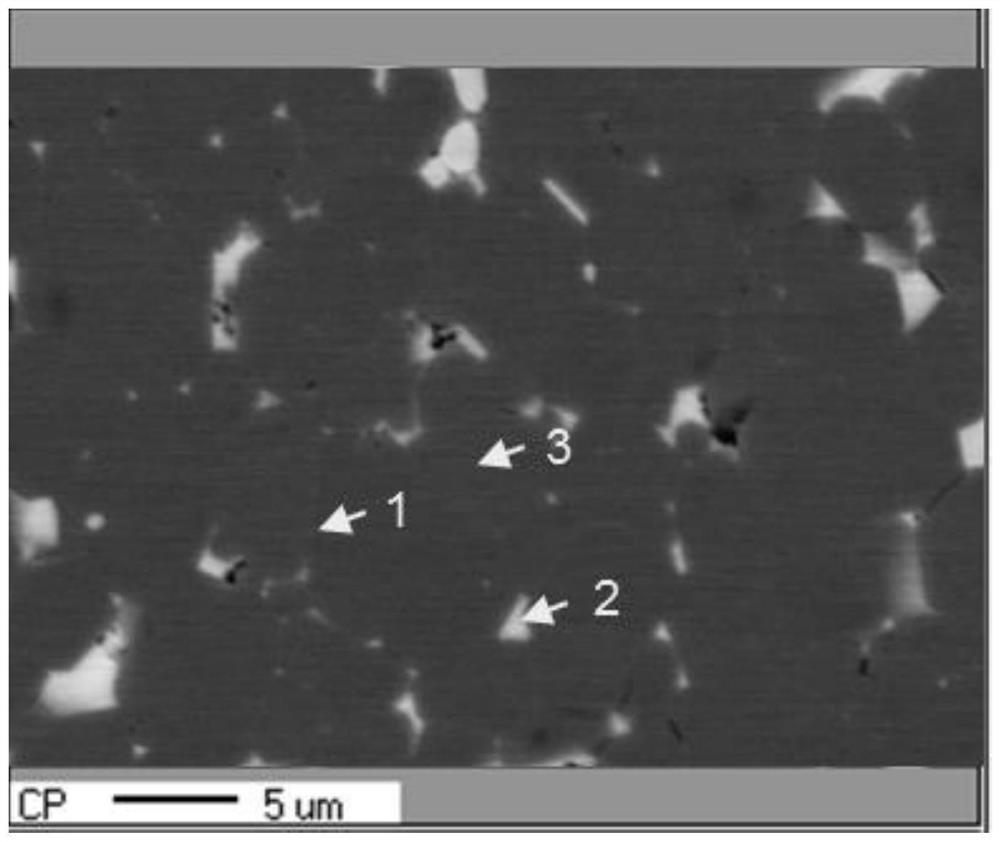

Image

Examples

preparation example Construction

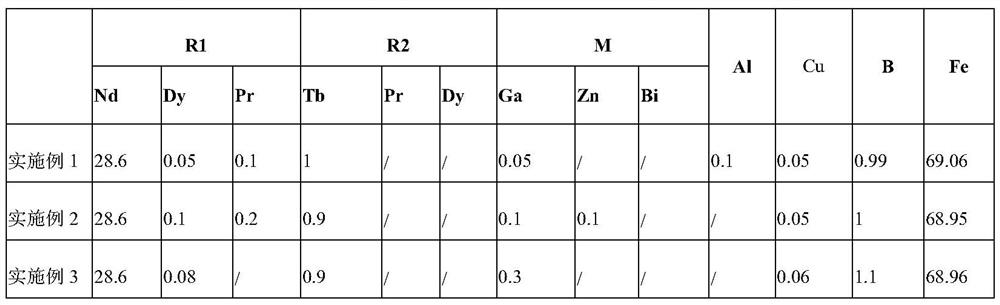

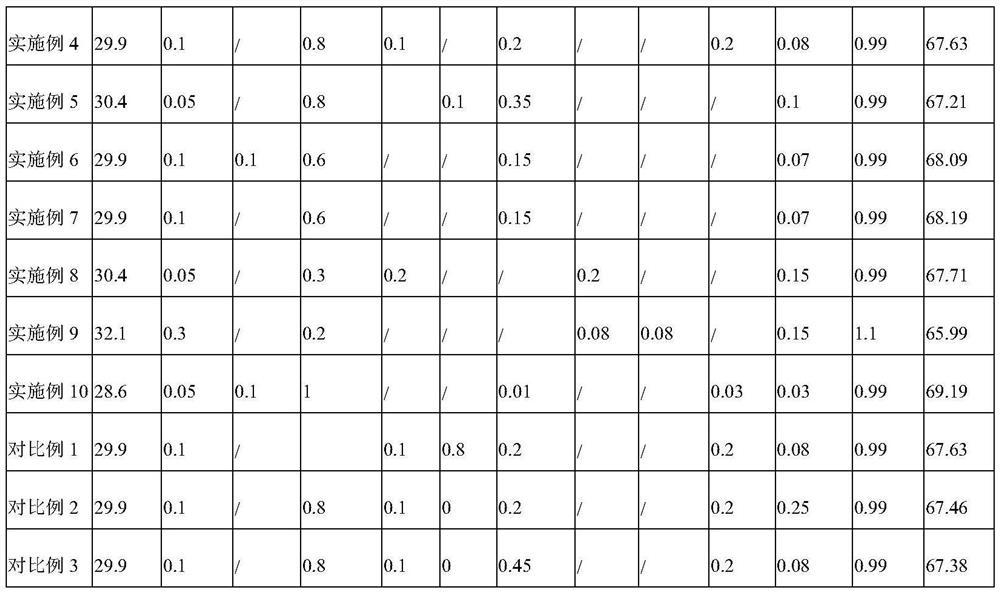

[0150] 2, the preparation method of NdFeB magnet material in embodiment 1

[0151] (1) Smelting and casting process: according to the formula in table 1, the prepared addition R2 (R2 in the embodiment 4 and 8 is added in the form of PrCu, the content of Cu added in the grain boundary diffusion step in the embodiment 4 and 8 Respectively 0.05wt% and 0.03wt%, Cu is in the smelting step, the content that adds is respectively 0.03wt% and 0.12wt%) Raw materials other than put into the crucible of alumina, in the high-frequency vacuum smelting furnace with 0.05Pa Vacuum melting is carried out under the conditions of vacuum and 1500°C. Argon gas is introduced into the intermediate frequency vacuum induction quick-setting belt furnace for casting, and then the alloy is quenched to obtain alloy sheets.

[0152] (2) Hydrogen crushing process: Vacuumize the hydrogen crushing furnace where the quenched alloy is placed at room temperature, and then pass hydrogen gas with a purity of 99.9%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com