Plastic weaving shuttle

A technology of plastic shuttle and shuttle body, which is applied in the field of weaving plastic shuttle, which can solve the problems of large contact friction and fluffing of warp yarns, and achieve the effect of reducing contact friction and uniform weft yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

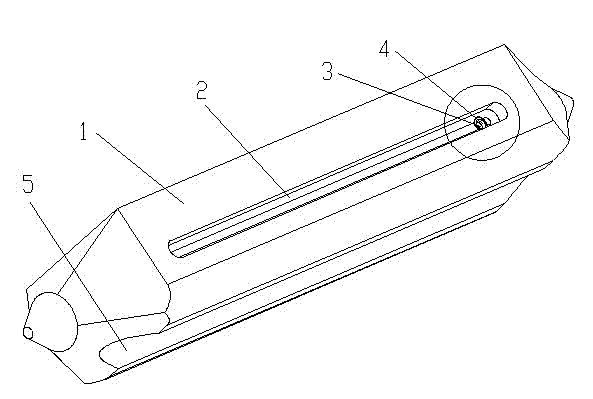

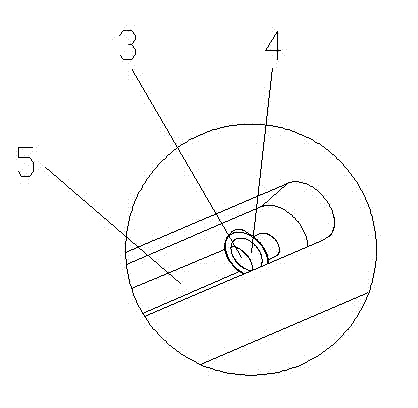

[0013] as attached Figure 1-3 The shown a weaving plastic shuttle of the present invention includes a shuttle body 1, a yarn guard groove 2, and a yarn guide porcelain eye 3; the yarn guard groove 2 is arranged on one side of the shuttle body 1; the yarn guard One end of the groove 2 is provided with a yarn guide porcelain eye 3; the bottom of the shuttle body 1 is provided with a groove 5;

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

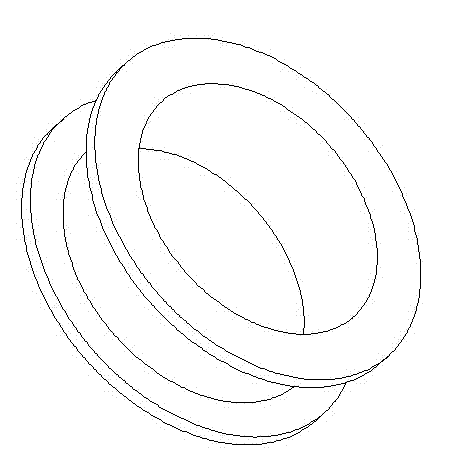

[0015] The plastic weaving shuttle of the present invention has grooves on the bottom of the shuttle body, which reduces the contact friction to the warp yarns of the lower layer, so that the warp yarns will not fluff. And because the nylon ring is put on the yarn-guiding porcelain eye, the weft yarn has the tension required in the process whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com