A Fiber Bragg Grating Pressure Sensor

A pressure sensor, fiber grating technology, applied in the direction of fluid pressure measurement, measurement of fluid pressure, instruments, etc. using optical methods, can solve the problems of temperature interference, electromagnetic interference, affecting measurement accuracy, etc., to eliminate temperature interference and increase temperature measurement. Functions, effects with a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

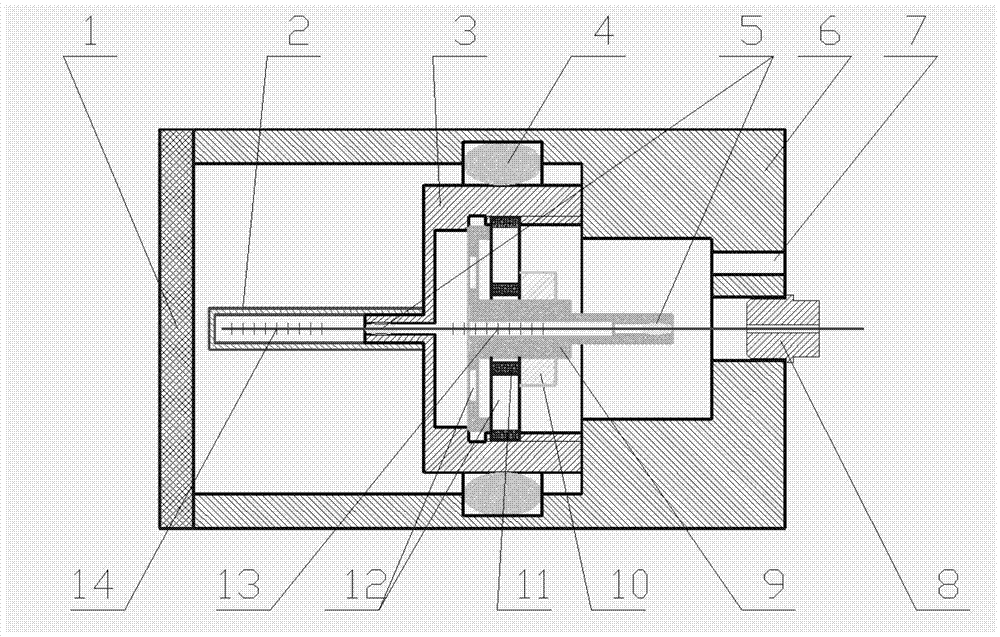

[0029] like figure 1 As shown, a fiber Bragg grating pressure sensor includes an outer protection tube 6 , a pressure measuring fiber Bragg grating 13 , a temperature measuring fiber Bragg grating 14 , a fixed pressure plate 11 , an elastic substrate 9 and an elastic diaphragm 3 . The elastic diaphragm 3 is arranged in the outer protection tube 6, and separates the outer protection tube 6 to form a measured fluid cavity and a reference fluid cavity, the measured fluid cavity communicates with the measured fluid, and the reference fluid cavity communicates with the atmosphere. The outer protection tube 6 is provided with a filter screen 1 on one side of the measured fluid chamber, and a plug 8 and an atmosphere communication hole 7 are provided on the side of the reference fluid chamber, so that the reference fluid chamber and the atmosphere are connected, effectively eliminating the residual gas pressure inside the sensor or The effect of changes in external atmospheric pressu...

Embodiment 2

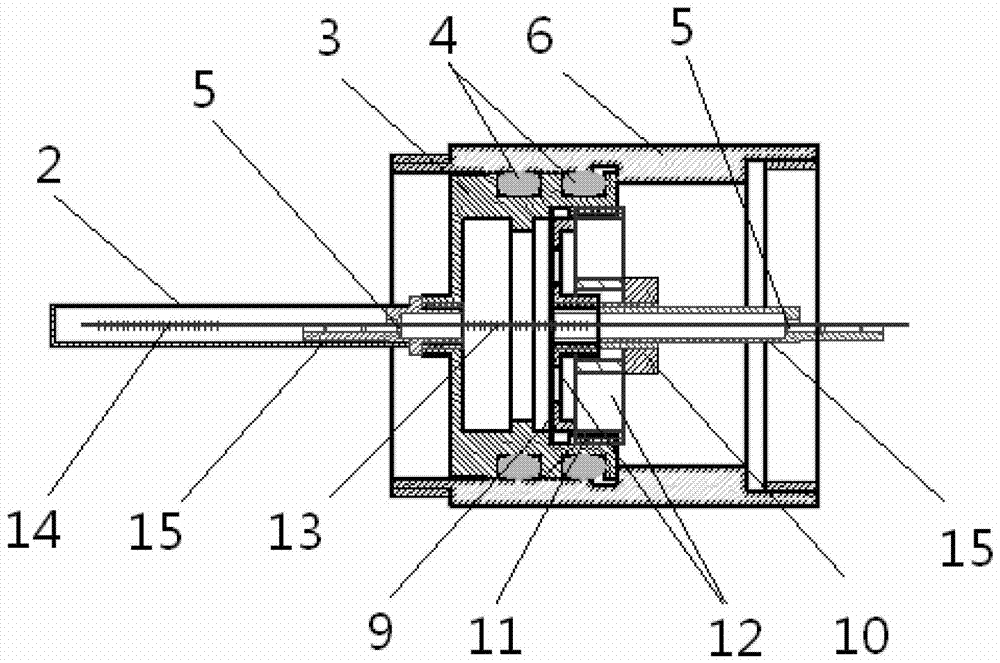

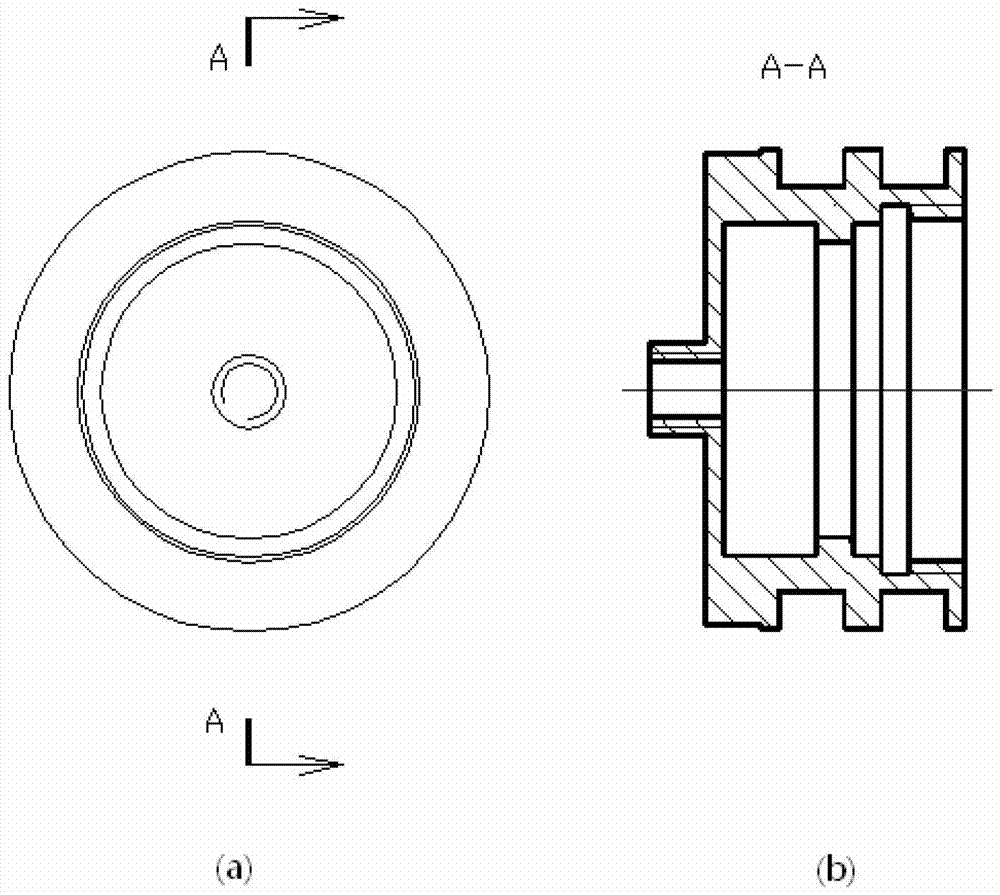

[0034] like Figure 2~4 As shown, there are two "O"-shaped sealing rings 4 of the fiber grating pressure sensor in this example, and the installation grooves are opened on the elastic diaphragm. Each of the elastic substrate 9 and the fixed platen 11 has a set of vent holes 12, wherein the number of vent holes 12 on the elastic substrate 9 is four, and the number of vent holes 12 on the fixed platen 11 is six. The welding point 5 of optical fiber can be located on a base 15, and this base 15 can directly be made into an integral body with elastic diaphragm 3, elastic substrate 9, also can be used as separate parts with elastic diaphragm 3, elastic substrate 9 connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com