Self-locking bearing groove with self-provided locking buckle of elastic ring on working wing

A technology of self-locking brackets and elastic rings, applied in the direction of brackets, arch wires, etc., can solve the problems of patient discomfort, fracture, cumbersome and inconvenient wire removal operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

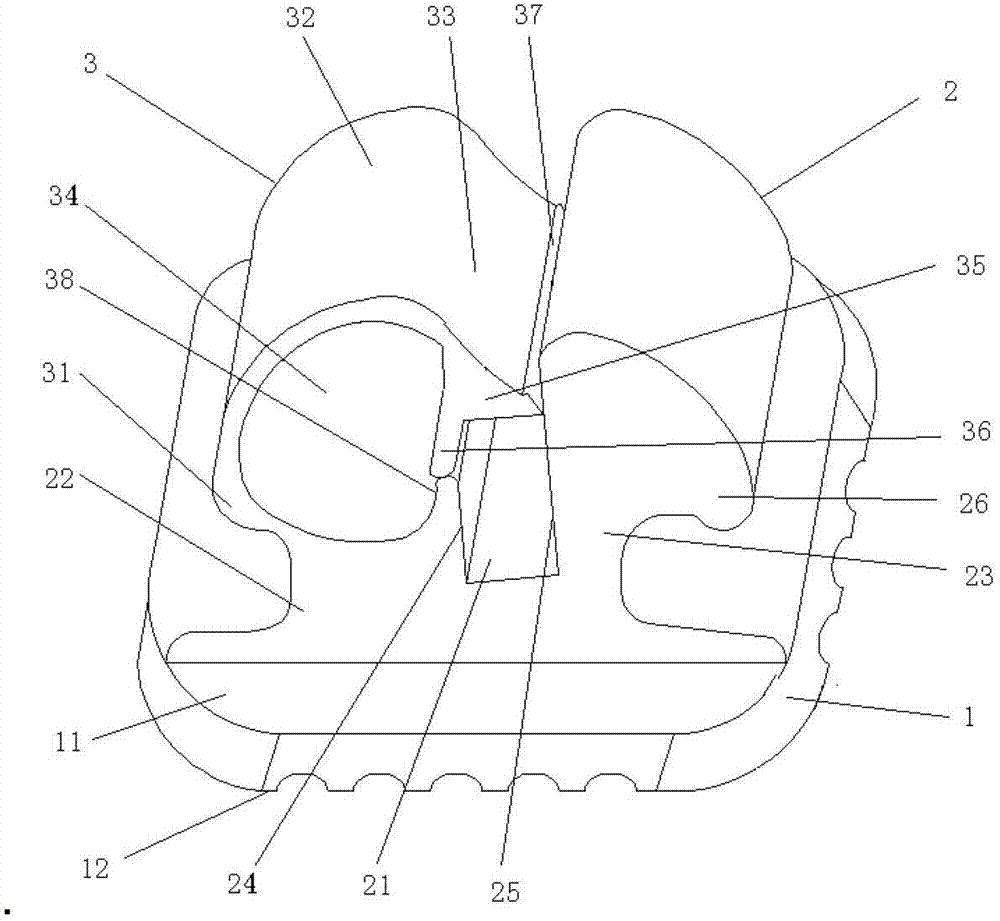

[0040] Such as figure 1 As shown, the self-locking bracket of this embodiment includes a bracket bottom plate 1 , working wings 2 and elastic ring lockers 3 , and each working wing 2 is provided with an elastic ring locker 3 . Among them, the front of the bracket bottom plate 1 is the lip and buccal surface 11, and the back is the adhesive surface 12. The lip and buccal surface 11 is a smooth plane, and the adhesive surface 12 is provided with a gully-like texture, which is conducive to the inflow of adhesive and strengthens the self-locking bracket. Adhesive retention. The working wing 2 includes a base connected to the surface 11, and a groove 21 formed by the top of the base recessed downward for installing an orthodontic archwire. The grooves 21 of all the working wings 2 are on a groove axis. The base is divided into the first base 22 on one side of the groove axis and the second base 23 on the other side of the groove axis by the groove 21, the groove wall on the first ...

Embodiment 2

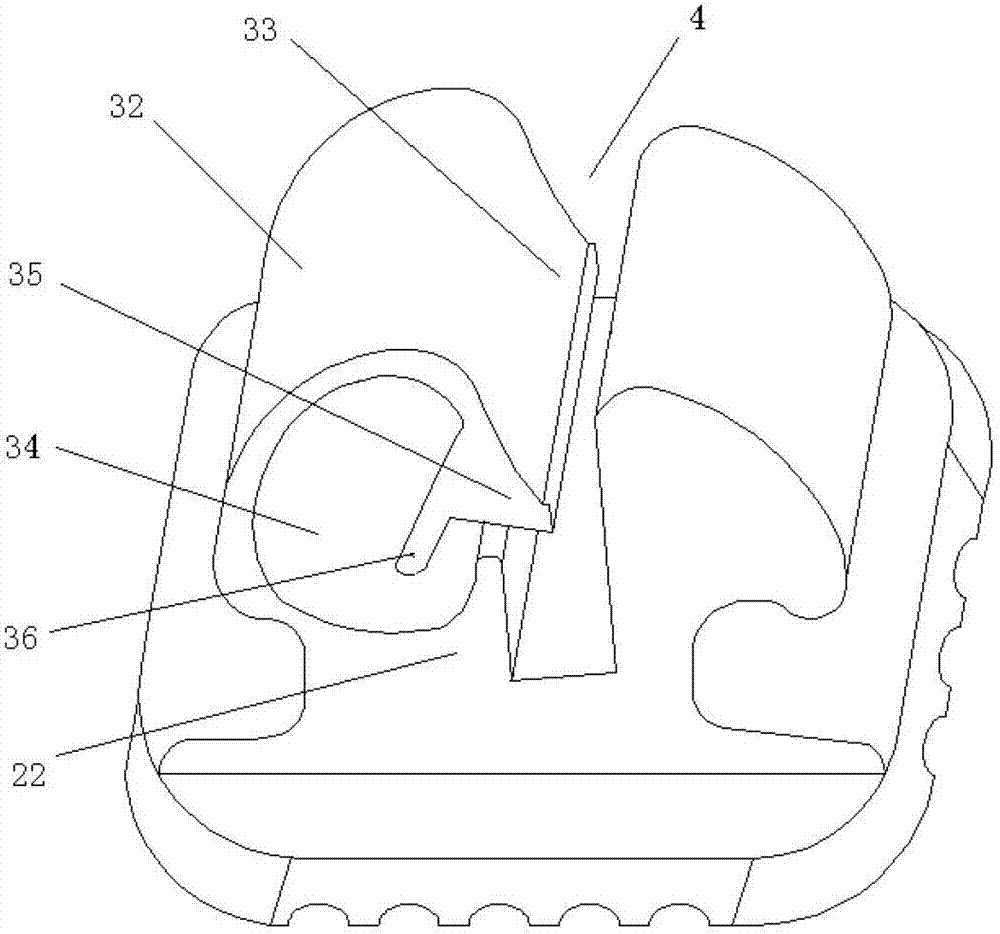

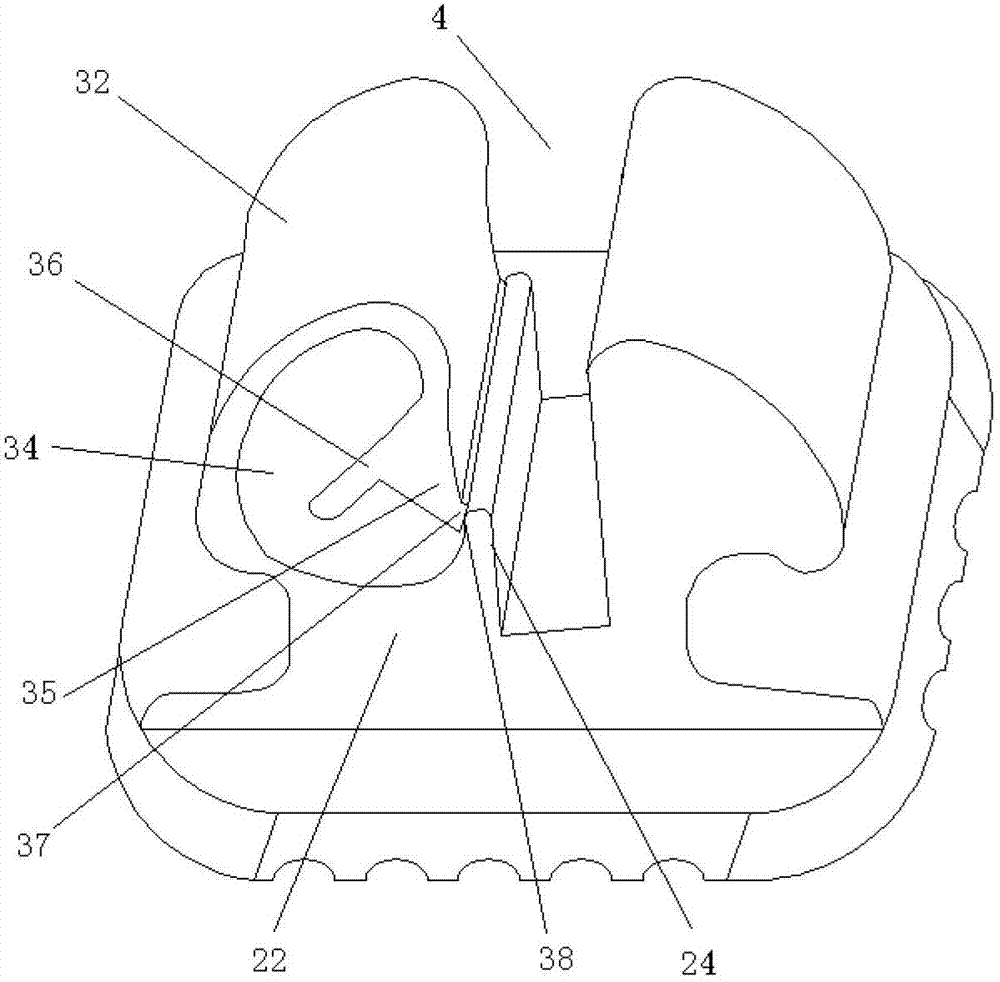

[0046] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that a piece 39 protrudes from the end of the free end 33 toward the inner side of the elastic piece 32 . Such as Figure 6 , Figure 7 As shown, when the elastic piece 32 is deformed, the end of the supporting piece 39 is closer to the inner surface of the elastic piece, until the deformation of the elastic piece 32 reaches a certain degree, the end of the supporting piece 39 is against the inner surface of the elastic piece 32, limiting the continued deformation of the elastic piece 32 . Such as Figure 8 As shown, when the free end 33 is subjected to an external force and the shrapnel 32 is deformed, the card 35, the blocking piece 36, and the support piece 39 move synchronously, so that the entrance 4 of the archwire groove is formed, the archwire is restricted in the archwire groove and the shrapnel is restricted. 32 The function of excessive deformation is completed in one s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com