Unidirectional-transparent printing material used in LED display screen

An LED display, one-way perspective technology, applied in printing, copying/marking methods, layered products, etc., can solve problems such as unrealizable, single advertising, and different, saving space, high screen accuracy, and ink absorption. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

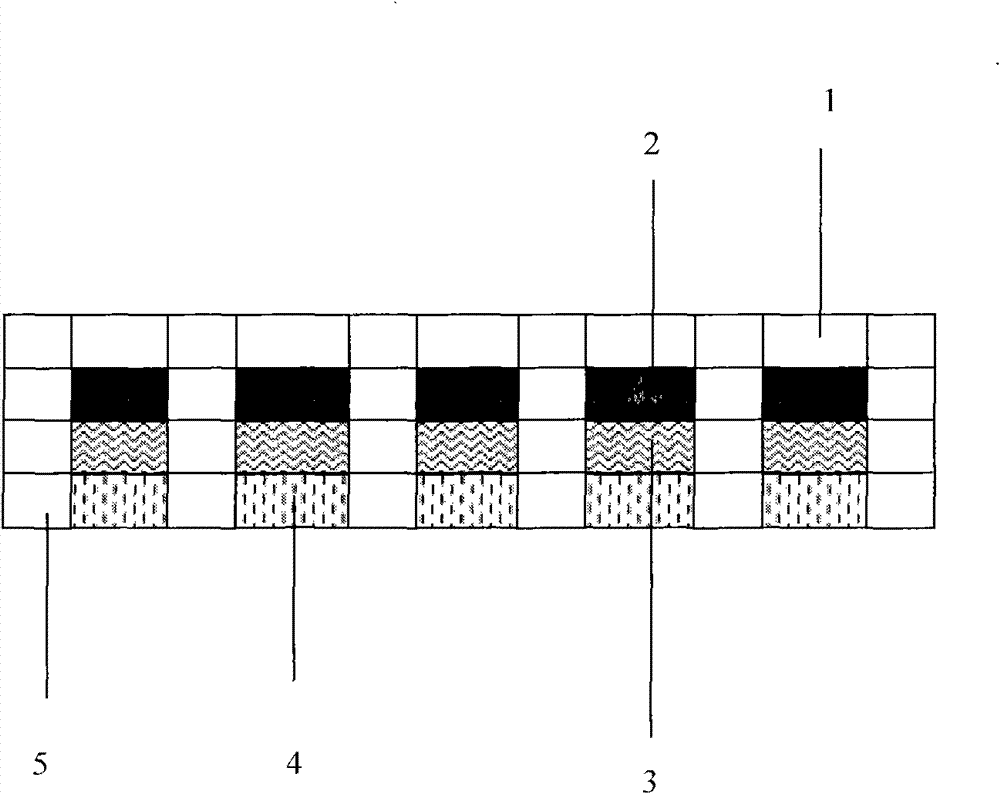

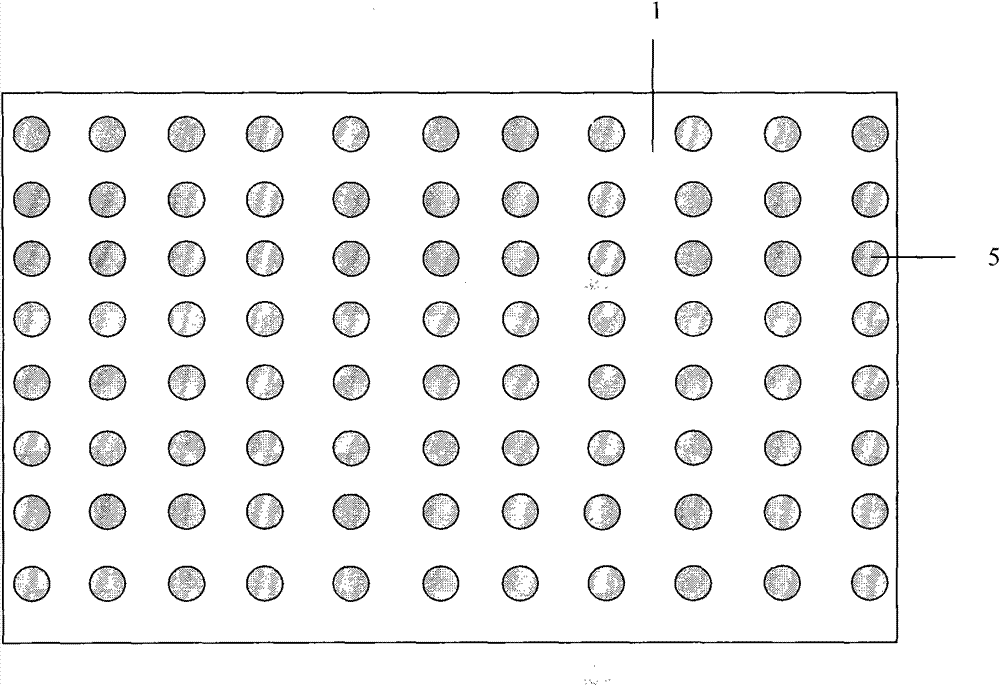

[0017] See attached figure 1 , 2 , the one-way see-through printing material for LED display consists of the upper printing substrate layer 1 using white PVC film and the lower layer using black PVC film as the bottom layer 2, which is laminated by heating. The white PVC film is used as the printing substrate layer 1, and the black PVC film The film is used as the bottom layer 2, and a layer of transparent acrylic pressure-sensitive adhesive is coated on the surface of the bottom layer 2 as the glue layer 3, so that the bottom layer 2 and the opaque paper layer 4 are bonded by the glue layer 3, and the entire surface Through-holes 5 are perforated in a square arrangement in the vertical direction. The diameter of the through-holes 5 is Φ4.5mm, and the hole spacing is 15mm. The paper layer 4 sticks the one-way transparent film on the LED display screen, and the through hole 5 exposes the LED light-emitting diode, which is used for advertising and marking day and night.

Embodiment 2

[0019] See attached figure 1 , 2 , use white PVC film as the printing substrate layer 1, and coat a layer of black pressure-sensitive adhesive layer on the surface of the printing substrate layer 1 as the bottom layer 2 to form a one-way perspective film, and then use the black pressure-sensitive adhesive layer as the glue on the bottom layer 2 Layer 3 is pasted with a layer of opaque paper layer 4, and through-holes 5 are perforated in the vertical direction of the entire sheet in a square arrangement. The diameter of the through-holes 5 is Φ4.5mm, and the hole distance is 30mm. The film printing substrate layer 1 sprays graphics and text, removes the opaque paper layer 4, and sticks the one-way see-through film on the LED display screen. The through hole 5 reveals the LED light-emitting diode, which is used for advertising and marking day and night.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com