Bicycle wheel rim structure

A technology for bicycles and rims, applied in the direction of wheels, spoked wheels, rims, etc., can solve the problems of uneven spoke tension, shortened service life, fatigue effect, etc., to eliminate fatigue effect, prolong service life, and reduce fatigue effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

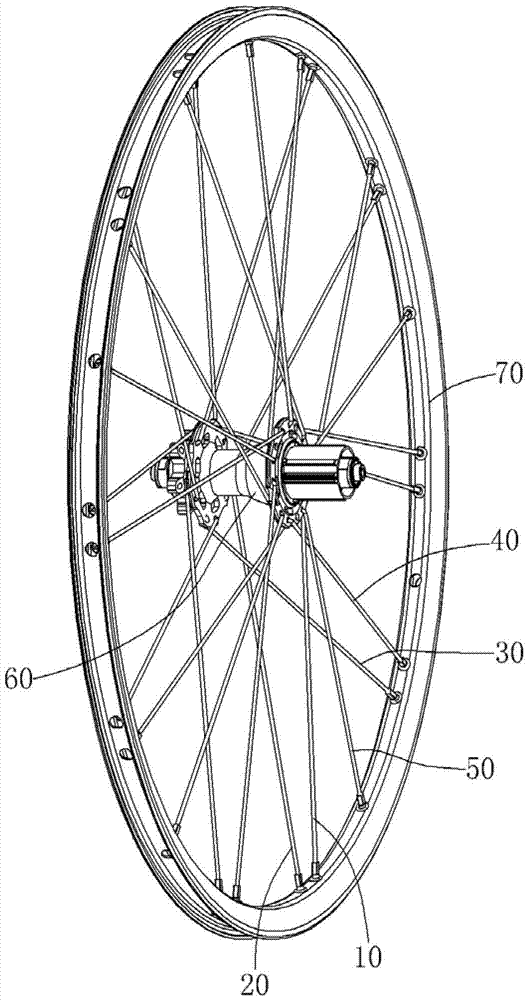

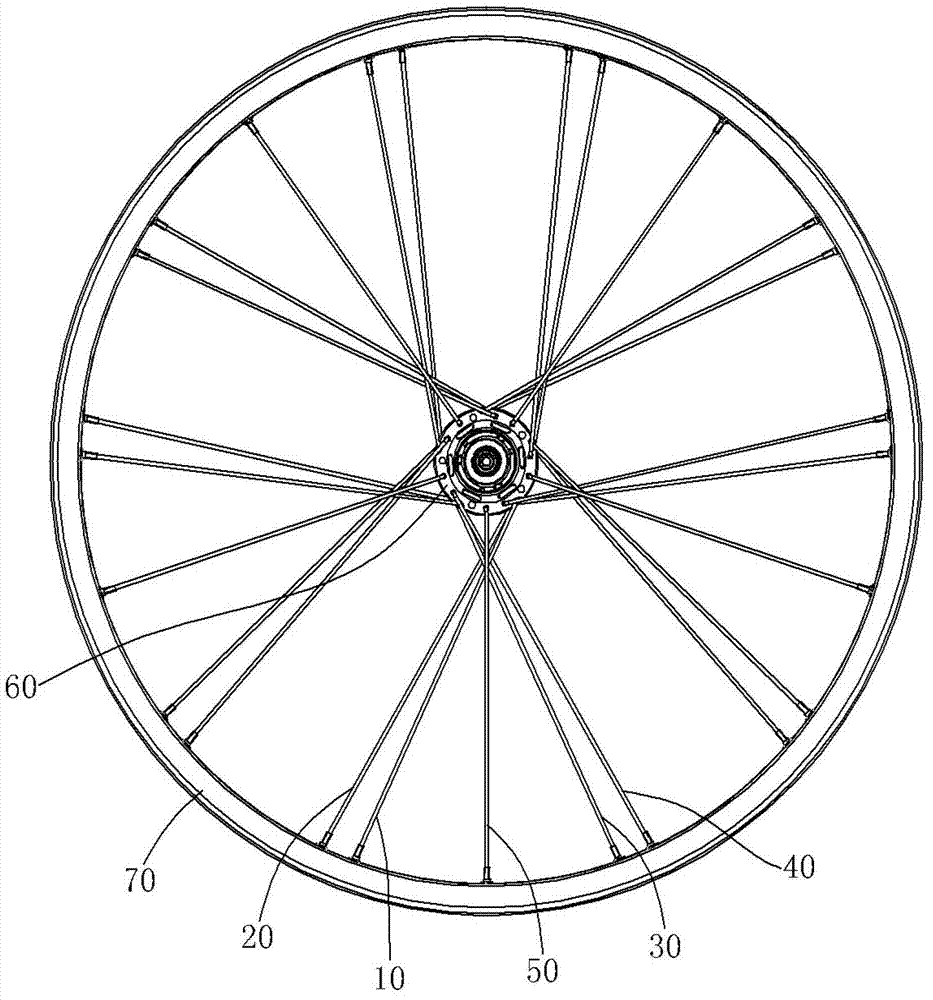

[0027] A bicycle rim structure, see Figure 1 to Figure 3 As shown, it includes a hub 60, a spoke and a rim 70. The driving end of the hub 60 is provided with a drive mechanism, the drive mechanism is a sprocket mechanism, and the two ends of the spoke are respectively connected to the hub 60 and the rim 70. A group of spokes is arranged into a group of spokes, and the spokes in each group of spokes are arranged and woven in a ratio of 2:3. The hub 60 and the rim 70 are connected with at least three groups of spokes, and each group of spokes is arranged along the wheel. Circle 70 round uniform ring display.

[0028] In a preferred embodiment, 3-10 groups of spokes are connected to the hub 60 and the rim 70 . The bicycle rim 70 illustrated in this embodiment has 5 groups of spokes, see Figure 1 to Figure 3 shown.

[0029] Among the 50 spokes of the spoke group, 3 spokes are connected to the driving end of the hub 60 , and 2 are connected to the non-driving end of the hub 60...

Embodiment 2

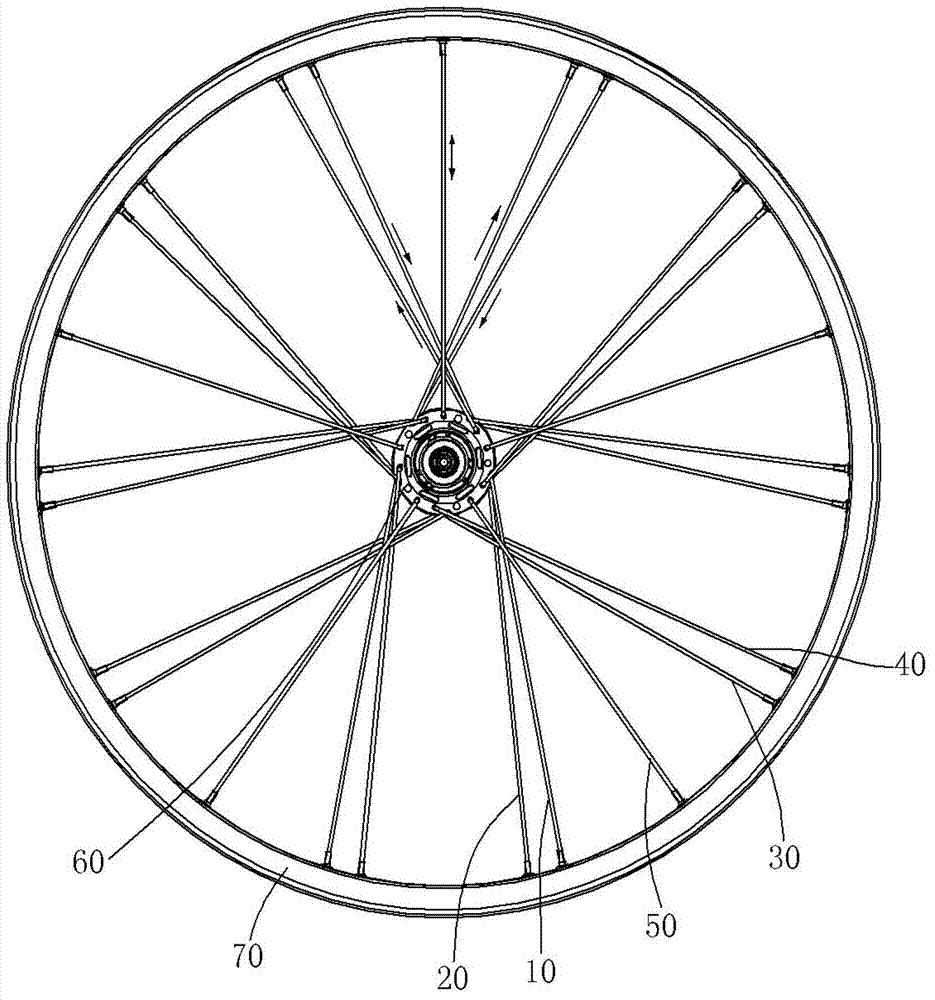

[0040] The main structure and advantages of this embodiment are the same as those of Embodiment 1, Figure 4-5As shown, no further description here, the difference is that: the driving end of the hub 60 is provided with a disc brake device, the rim 70 is provided with 5 groups of spokes, and the driving end of the hub 60 is connected with 5 fifth spokes 50 , the non-driving end is not connected to the fifth radial wire 50 .

[0041] Wheel rim 70, hub 60, spokes, sprocket mechanism and disc brake device have been widely used at present, and other structures and principles are the same as the prior art, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com