High-salinity high-chromaticity printing and dyeing wastewater recovery process and equipment thereof

A printing and dyeing wastewater and high salinity technology, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, limited wide application, and high energy consumption in operation. Achieve the effect of low cost, good treatment effect and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

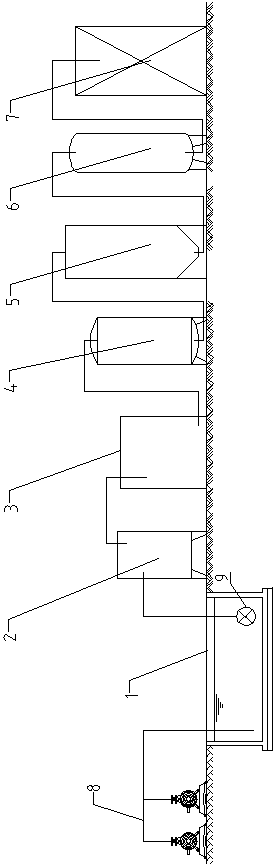

[0039] A recovery process for printing and dyeing wastewater with high salinity and high chroma, comprising the following steps:

[0040] (1) After the high-salinity wastewater generated in the printing and dyeing process is collected, it enters the wastewater regulating tank 1, and the first chemical acid, such as hydrochloric acid, is added to adjust the pH=6, and the wastewater in the regulating tank 1 is aerated and stirred by the blower unit 8 , the air-water ratio is kept at 3:1 to achieve the purpose of homogeneity and quantity;

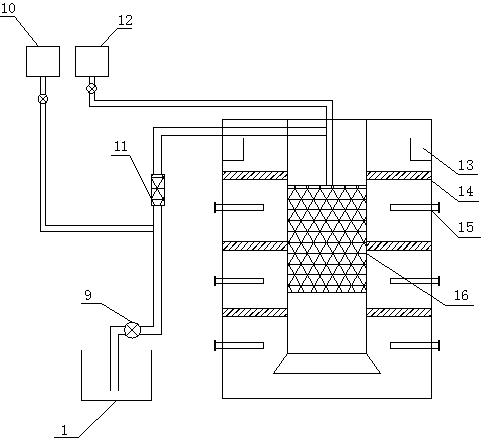

[0041] (2) The wastewater in the regulating tank 1 is lifted to the first advanced oxidation device 2 through the wastewater lifting pump 9 to dissolve the second drug Fe 2+ , the third drug H 2 o 2 Enter the mixing reactor 16 after being mixed with waste water in the pipeline mixer 11, and the dosing amount is: 0.8g / L Fe 2+ , 1.2ml / L H 2 o 2 , reaction time 30min, TiO in the first advanced oxidation device 2 2 Under the catalysis of lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com