Fillet rolling nodular cast iron crankshaft and machining technology thereof

A technology of filleting and rolling, which is applied in the direction of the crankshaft, can solve the problems of high price, poor reliability and wear resistance, and achieve the effect of improved roughness of finished products, high impact value and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

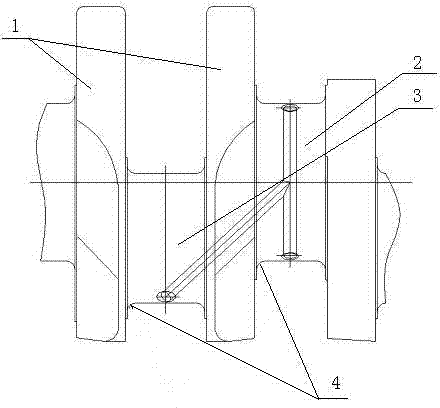

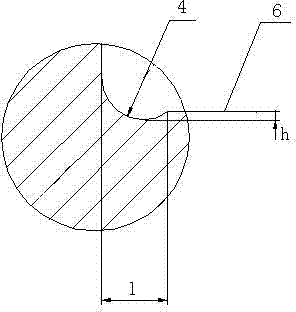

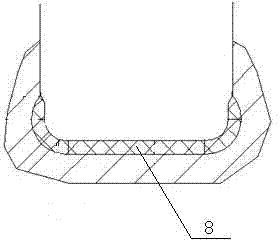

[0016] The structure of the forged steel large fillet quenching crankshaft in the prior art is as follows: figure 1 and image 3 As shown, including the main journal 2 and the connecting rod journal 3, the main journal 2 and the connecting rod journal 3 are installed between the crank arm 1, the fillet 4 of the main journal and the connecting rod journal is R5, and the journal and the fillet are used The overall quenching process, the thickness of the hardened layer 8 is 2.0~5.0mm, the fillet to the push block is not less than 5.5mm, and the rest of the block is not less than 5mm to ensure that the boss is hardened. Due to this large fillet structure, part of the material is higher than the surface of the journal during the rolling process, and the reliability and wear resistance are relatively poor, so the use of forged steel materials is expensive.

[0017] The structure of the rounded rolling nodular iron crankshaft of the present invention is as figure 2 and Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com