Full-graduation concrete fracture expanding test testing machine under action of high water pressure and mobile load

A high water pressure and concrete technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficult to realize the crack growth process and the inability to test the crack growth process, and achieve the effect of avoiding complexity and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

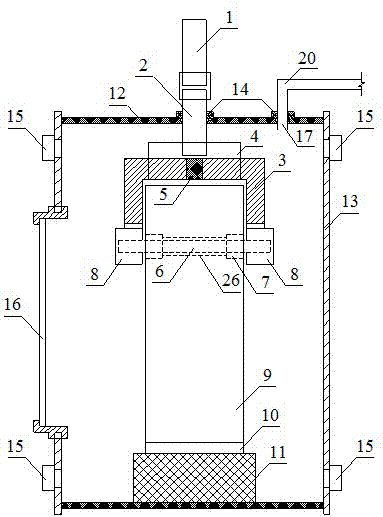

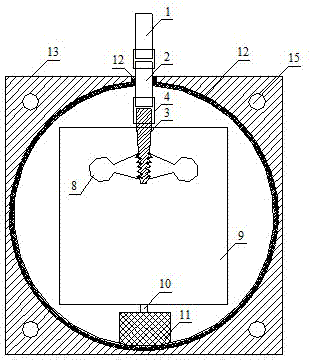

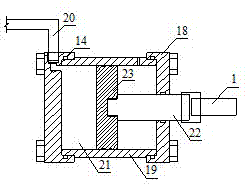

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] like figure 1The full-graded concrete fracture propagation test machine under the action of high water pressure and dynamic load is shown, including the MTS test machine operating head (1), wedge-shaped loading frame (3), loading frame fixing parts (4), NdFeB rare earth Permanent magnet (5), tension and pressure transmission steel shaft (6), embedded bearing (7), tension and compression support (8), sample support steel rod (10), sample support (11), high pressure seal Cylinder (12), sealed cylinder cover plate (13), sealed cylinder connecting rod (15), non-contact optical measurement window (16), high water pressure pump (18) and high water pressure connecting pipe (20), its characteristics In: MTS testing machine actuating head (1), actuating connecting rod (2), wedge-shaped loading frame (3), loading frame fixture (4), NdFeB rare earth permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com