Novel dual-frequency patch antenna with resonance ring microstructure array

A technology of microstructure array and patch antenna, which is applied in the direction of antenna, antenna array, radiating element structure, etc., can solve the problems of pattern distortion, unfavorable large-scale production and processing, and cross polarization deterioration, so as to avoid the limitation of antenna size Increase, excellent radiation characteristics, and solve the effect of easy distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

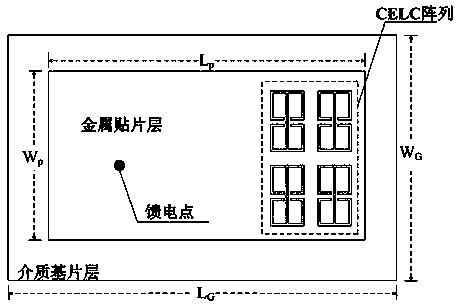

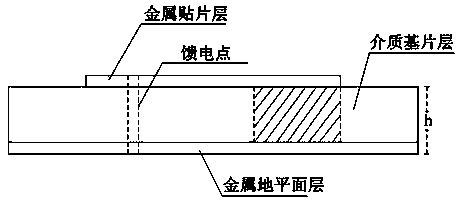

[0043] Such as figure 1 A top view of a double-sided copper-clad PCB is shown, and figure 2 The front view of the double-sided copper-clad PCB board is shown, in which the metal patch layer is located at the top and its area is smaller than the dielectric substrate layer. The number of the metal patch layer is one layer and it is made of copper; the dielectric substrate layer is located on the Below the metal patch layer, its length, width and height are:

[0044] W G =λ / 1.2

[0045] L G =λ / 1.7

[0046] h=λ / 170

[0047] Wherein λ is the vacuum wavelength corresponding to the central operating frequency of the low frequency band of the patch antenna; a metal ground plane layer is also fixed below the dielectric substrate layer, and the length and width of the metal ground plane layer are the same as the dielectric substrate layer, wherein There is also a feed point installed on the metal patch layer, and the feed point is a linear distance from the left side of the metal p...

Embodiment 2

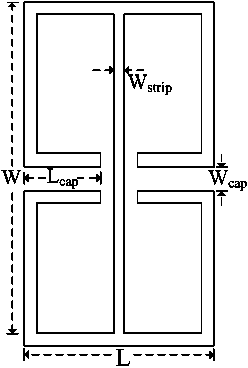

[0065] Such as Figure 9 The difference between the top view of the patch antenna shown in Embodiment 1 is that the radiating unit adopts the following Figure 8 The CSRR single-ring unit shown, the CSRR single-ring unit is a square surrounded by four grooves, one side is broken from the middle to form two fractures, and the two fractures are bent 90 degrees to the inside of the square After that, extend a small section parallel to each other, such as 1cm. The distance between two of the fractures:

[0066] W cap =λ / 1713

[0067] The length of the fracture is:

[0068] L cap =λ / 144.3.

[0069] The resonant ring microstructure array is formed by arranging a total of 3 x 3 CSRR single-ring units etched on the metal patch layer.

[0070] Since the entire array has 9 CSRR single-ring units, the area where the dielectric constant of the dielectric substrate can be affected by CSRR is larger than that of the CELC in Example 1, which can further increase the high-to-low freque...

Embodiment 3

[0073] The difference from Embodiment 1 is that in this embodiment, the resonant ring microstructure array consists of Figure 11 The four CSRR bicyclic units shown are arranged in an arrangement.

[0074] Such as Figure 10 The CSRR double-ring unit shown has two inner rectangles surrounded by bar-shaped grooves

[0075] and the outer rectangle. The inner rectangle is located inside the outer rectangle, and there is an opening in the middle of one long side of the outer rectangle. The width of the opening is: W cap =λ / 1754; At the same time, an opening is also provided in the middle of a side that is parallel to the long side of the outer rectangle and away from the long side of the inner rectangle, and the length of the opening is also W cap .

[0076] The remaining implementation methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com