Ultra-thin small-caliber high-resolution endoscopic microscope objective

A microscope objective, high-resolution technology, used in microscopes, telescopes, optics, etc., can solve problems such as narrow working clamps, delayed treatment, patient pain, etc., and achieve high-resolution processing, improved resolution, and good processability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

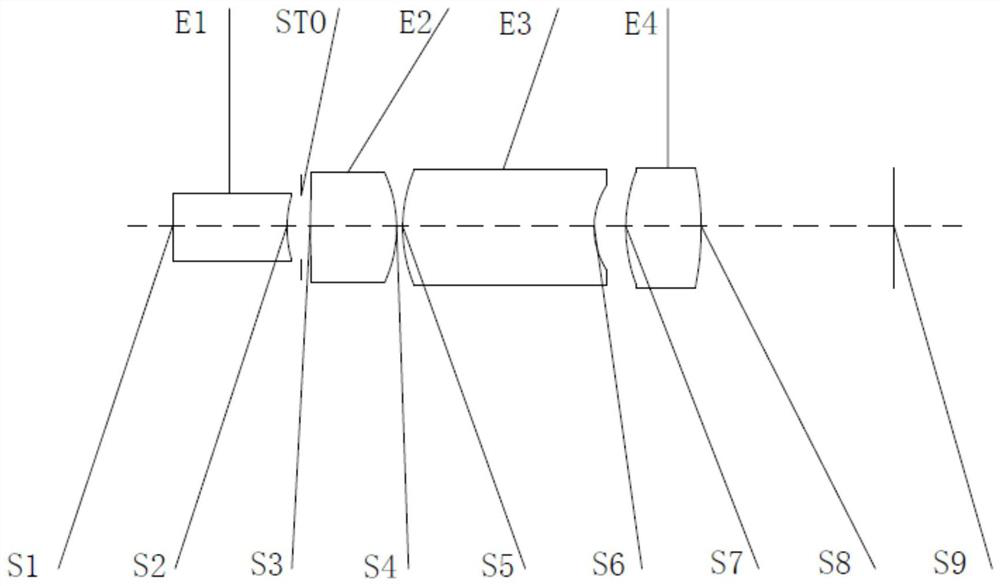

[0101] The surface type, curvature radius, thickness, semi-diameter and material of each lens in this embodiment are shown in Table 1.

[0102] Table 1 Embodiment 1 Endoscopic microscope objective lens parameters

[0103]

[0104]

Embodiment 2

[0106] The surface type, curvature radius, thickness, semi-diameter and material of each lens in this embodiment are shown in Table 2.

[0107] Table 2 Embodiment 2 endoscopic microscope objective lens parameters

[0108] face number surface type Radius of curvature (mm) Thickness (mm) Semi-aperture(mm) Material OBJ sphere endless 0.1511 0.1760 S1 sphere endless 0.5748 0.1707 1.50,66.2 S2 sphere 0.5734 0.0721 0.1565 STO sphere endless 0.0454 0.1620 S3 sphere 3.7036 0.4341 0.1842 1.69,21.2 S4 sphere -0.6595 0.0300 0.2711 S5 sphere 0.7519 0.9625 0.2909 1.75,35.0 S6 sphere 0.3889 0.1592 0.2126 S7 sphere 0.8001 0.3795 0.2782 1.75,35.0 S8 sphere -1.5341 0.9690 0.3000 S9 sphere endless 0.3010

Embodiment 3

[0110] The surface type, curvature radius, thickness, semi-diameter and material of each lens in this embodiment are shown in Table 3.

[0111] Table 3 Embodiment 3 endoscopic microscope objective lens parameters

[0112]

[0113]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com