Lactic acid-fermented egg having reduced egg protein antigenicity through addition of sodium citrate, heating treatment, and lactic acid fermentation, and method for preparing same

A technology of lactic acid fermentation and manufacturing method, which is applied in the field of lactic acid fermented eggs, can solve problems such as difficulty in ensuring sensory properties, unsmooth proliferation of lactic acid bacteria, poor sensory properties, etc., and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Beat 20 eggs (specification: special eggs) and achieve homogenization in a way that does not cause serious foaming, and filter through a 70 mesh (mesh) sieve to obtain 1000g of whole egg liquid after removing the egg band. Add 1700g of purified water, 60g of glucose, 180g of fructose, 55.2g of fructooligosaccharides, and 4.5g of sodium citrate to make an egg mixture. After heat treatment at 75°C for 15 minutes, immediately cool to 40°C. The weight of the egg mixture is 0.01% by weight, that is, 0.3g, which is inoculated with 25% of Lactobacillus acidophilus, 25% of Lactobacillus bulgaricus, 25% of Bifidobacterium longum, 25% of Streptococcus thermophilus (Streptococcus thermophilus) 25% mixed lactic acid bacteria starter cultured in a thermostat at 40°C for 6 hours and then cooled to below 4°C immediately after lactic acid fermentation to produce 3000g of lactic acid fermented eggs with significantly reduced antigenicity of egg protein.

[0041] For reference, as a resu...

Embodiment 2

[0043] Beat 20 eggs (specification: special eggs) and achieve homogenization in a way that does not cause serious foaming, and filter through a 70 mesh (mesh) mesh sieve to obtain 1000g of whole egg liquid after removing the egg band. Add 1700g of purified water, 60g of glucose, 180g of fructose, 55.2g of fructo-oligosaccharide, and 4.5g of sodium citrate to make egg mixture. After heat treatment at 80°C for 15 minutes, immediately cool to 40°C. The weight of the egg mixture is 0.01% by weight, that is, 0.3g, which is inoculated with 25% of Lactobacillus acidophilus, 25% of Lactobacillus bulgaricus, 25% of Bifidobacterium longum, 25% of Streptococcus thermophilus (Streptococcus thermophilus) 25% mixed lactic acid bacteria starter cultured in a thermostat at 40°C for 6 hours and then cooled to below 4°C immediately after lactic acid fermentation to produce 3000g of lactic acid fermented eggs with significantly reduced antigenicity of egg protein.

[0044] For reference, as a re...

experiment example

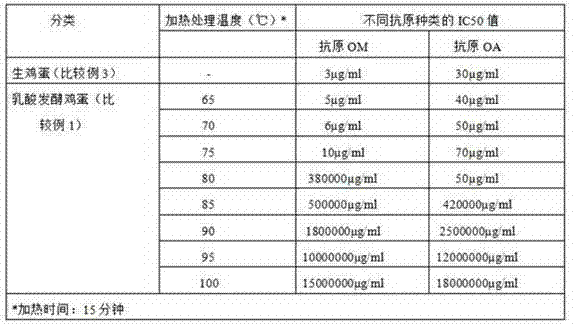

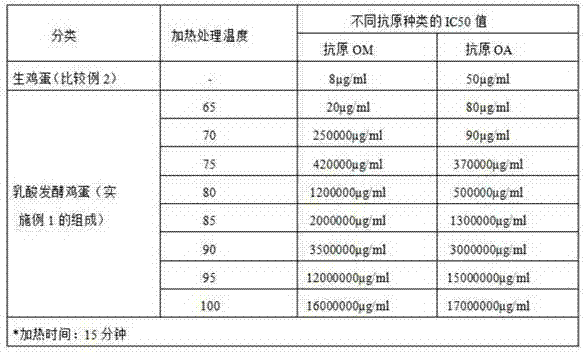

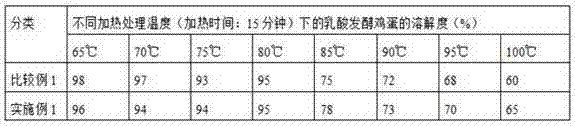

[0052] 1. Heat treatment and lactic acid fermentation of eggs

[0053] Homogenize after obtaining the whole egg liquid from eggs, filter with a 70 mesh (mesh) mesh sieve and remove the egg belt, add purified water, glucose, fructose and fructooligosaccharides here in the same way as in the above-mentioned embodiment 1, for adding and Example 1 The egg mixture manufactured with the same amount of sodium citrate (Example 1) or no addition (Comparative Example 1) was heat-treated at different temperatures (65°C to 100°C) for 15 minutes, and cooled to 40 ℃, inoculated with 25% of Lactobacillus acidophilus, 25% of Lactobacillus bulgaricus, 25% of Bifidobacterium longum, 25% of Bifidobacterium longum, and Streptococcus thermophilus (Streptococcus thermophilus) 25% ratio of mixed lactic acid bacteria starter cultured at 40 ° C for 6 hours to complete the lactic acid fermentation, immediately cooled and stored at 4 ° C or lower, and disclosed in the test.

[0054] On the other han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com