Liquid filter

一种液体过滤器、过滤器的技术,应用在膜过滤器、过滤分离、化学仪器和方法等方向,能够解决滤芯过滤面积缩小等问题,达到结合安全和可靠、排除安装错误的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

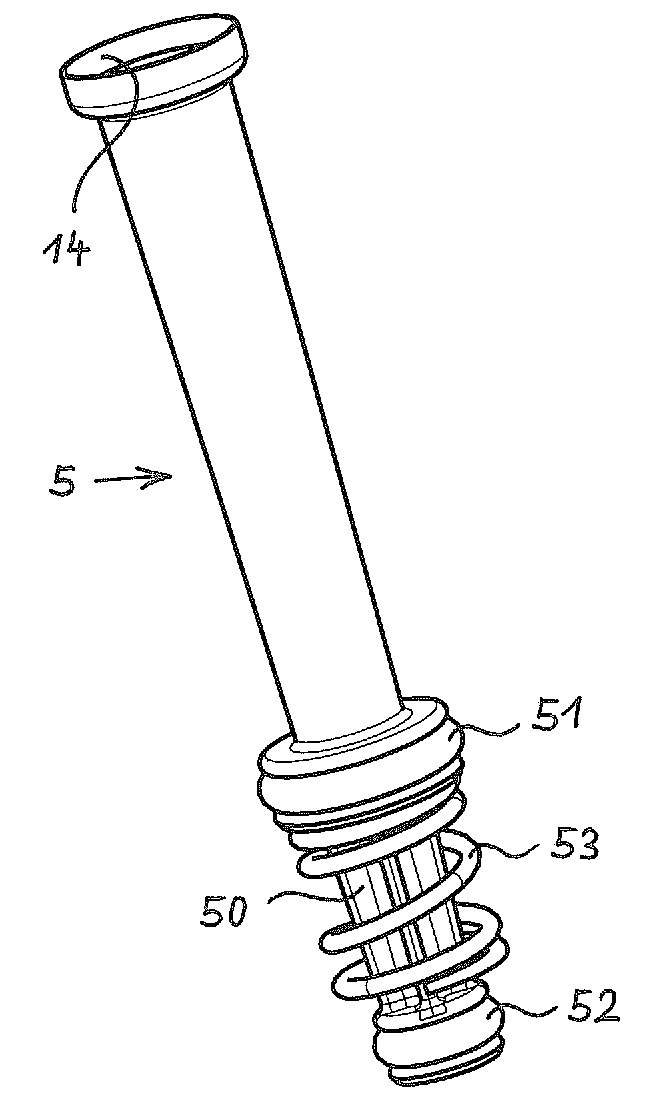

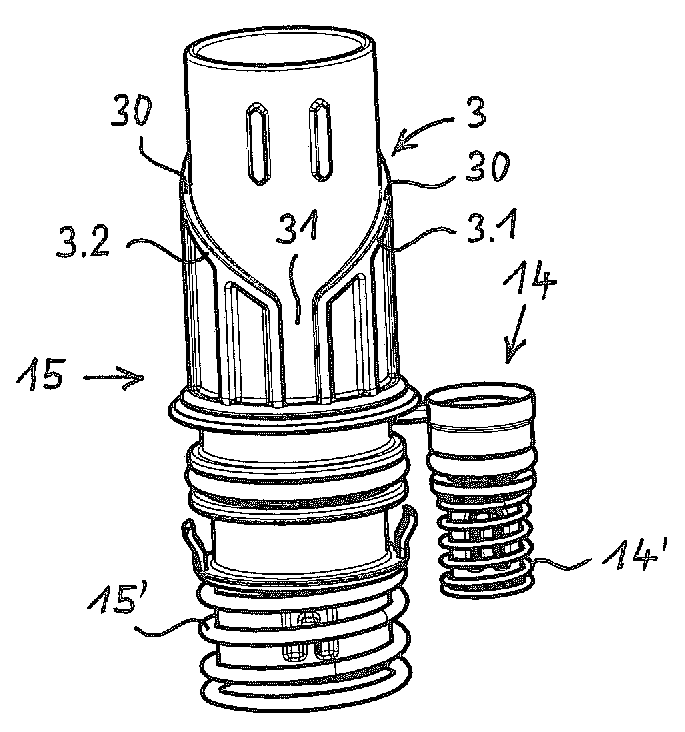

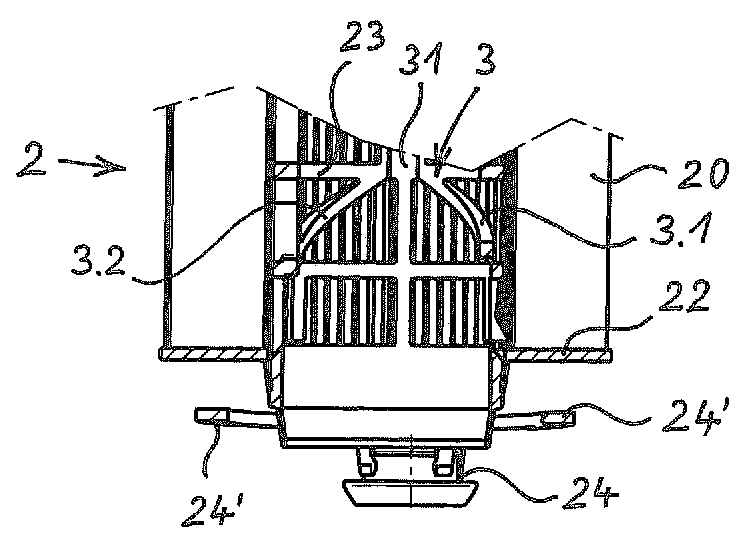

[0050] Figures 1 to 6 A first embodiment of a liquid filter according to the invention is shown. exist figure 1 and 2 The medium liquid filter is shown in longitudinal section in two different states. The filter 1 comprises a filter housing 10 which is closed on the upper side with a screw cap 16 . Inside the filter housing 10 an annular filter element 2 is arranged replaceably. The annular filter element 2 is formed by a filter material body 20 which is surrounded by end discs 21 , 22 on the top and bottom.

[0051] by in figure 1 and 2 The liquid to be filtered, eg the lubricating oil of an internal combustion engine, flows onto the raw side 10.1 of the liquid filter 10, which is not visible in the inlet. While flowing through the filter material body 20 , the liquid flows onto the clean side 10 . 2 of the filter housing 10 . The filtered liquid flows out through the return port 12 . Dirt particles are retained in the filter material body 20 .

[0052] Furthermor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com