Brine desalting method and system

A brine and desalination technology, applied in the field of desalination system, method and its desalination system, to remove soluble inorganic salts in concentrated brine, can solve the problems of low water yield, high energy consumption, high treatment cost, etc., and achieve water conductivity The effect of low efficiency, low energy consumption and high salt removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

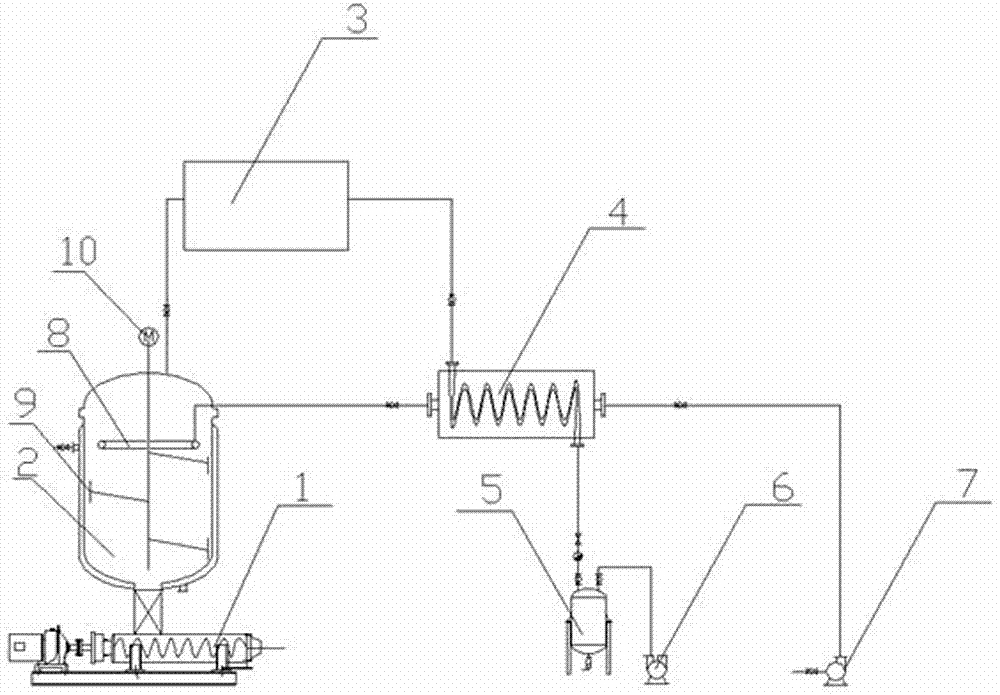

Embodiment 1

[0028] The low-temperature brine (with a salt content of 20%) obtained from 2,4-D production at 40°C enters the plate exchanger through a centrifugal pump, is heated to 80°C, and then enters an evaporator with a scraper (that is, a scraper evaporator, The same below) for spray evaporation, the water is evaporated instantly, the salt crystallization is scraped off by the scraper on the wall of the evaporator, and the scraped salt is output through the -0.15MPa air lock and the conveyor belt. The evaporated water vapor enters the compressor through the vacuum generated by the water ring vacuum pump, and the compressor compresses the lower-temperature water vapor into secondary steam at a temperature of 120°C, and the secondary steam enters the plate exchanger to provide heat energy for heating the low-temperature brine. The condensed water from the secondary steam enters the collection tank for recycling or further treatment.

[0029] According to the above steps, continue to ca...

Embodiment 2

[0032] The low-temperature brine (with a salt content of 13%) obtained from 2,4-D production at 30°C enters a heat pipe exchanger through a canned pump, is heated to 70°C, and then enters an evaporator with a scraper for spray evaporation. Evaporated instantaneously, the salt crystals are scraped off by scrapers on the wall of the evaporator, and the scraped salt is output through the -0.12Mpa air lock and conveyor belt. The evaporated water vapor enters the compressor through the vacuum generated by the water ring vacuum pump, and the compressor compresses the lower-temperature water vapor into secondary steam at a temperature of 110°C, and the secondary steam enters the heat pipe exchanger to provide heat energy for heating low-temperature brine , the water condensed from the secondary steam enters the collection tank for recycling or further treatment.

[0033] The purity of the salt output by the conveyor belt in this embodiment is 90.12%, the water content is 8.66%, and t...

Embodiment 3

[0035] The low-temperature brine (salt content: 6%) obtained from atrazine production at 20°C enters the coiled tube exchanger through a diaphragm pump, is heated to 65°C, and then enters an evaporator with a scraper for spray evaporation. Instant evaporation, salt crystallization on the wall of the evaporator is scraped off by a scraper, and the scraped salt is output through a -0.10Mpa air lock and a conveyor belt. The evaporated water vapor enters the compressor through the vacuum generated by the water ring vacuum pump, and the compressor compresses the lower-temperature water vapor into secondary steam at a temperature of 105°C, and the secondary steam enters the coiled tube exchanger to provide heating for low-temperature brine. The thermal energy, the water after the secondary steam condensation enters the collection tank for recycling or further treatment.

[0036] The purity of the salt output by the conveyor belt in this embodiment is 90.23%, the water content is 8.5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap