Paper inspection bench

An inspection table and paper technology, applied in the field of paper inspection table, can solve the problems of unguaranteed paper inspection quality, low work efficiency, large labor consumption, etc., so as to improve the paper inspection quality, reduce labor costs, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

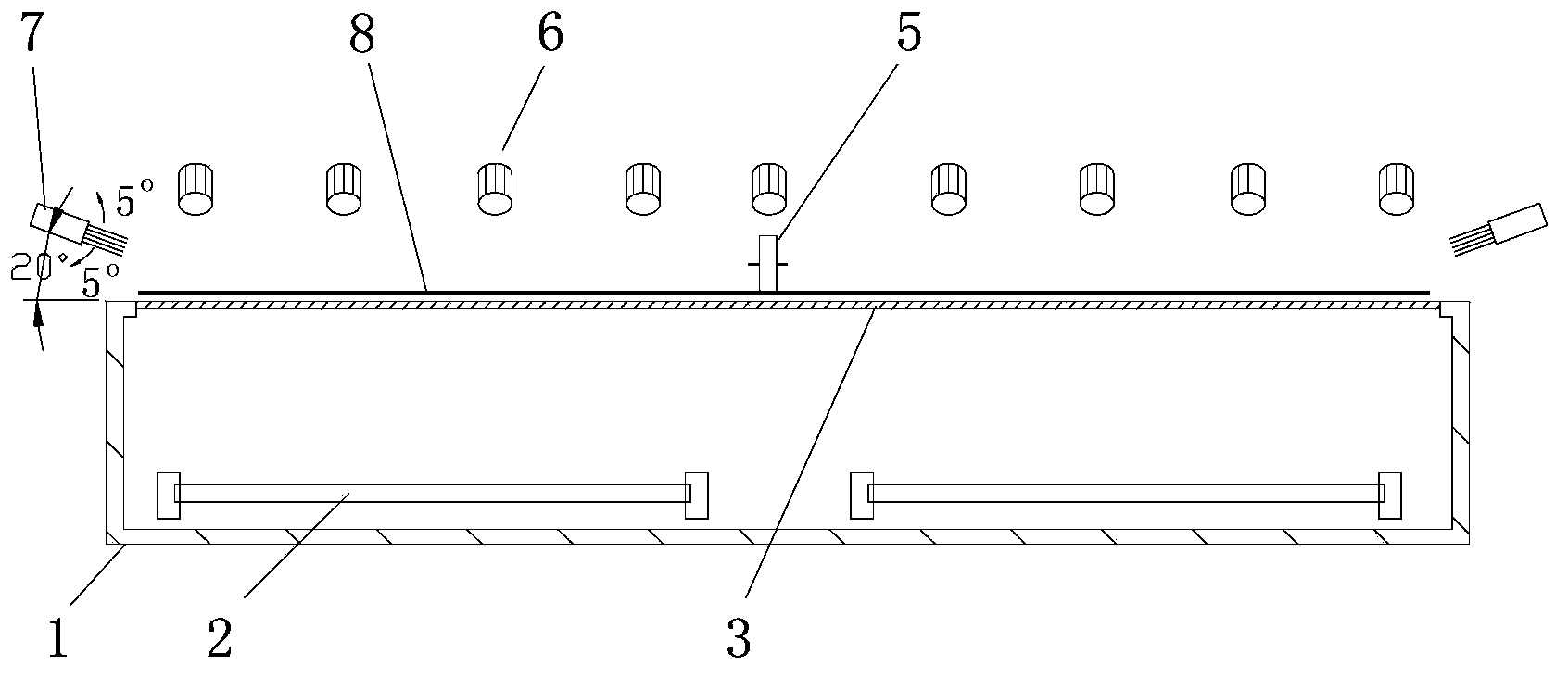

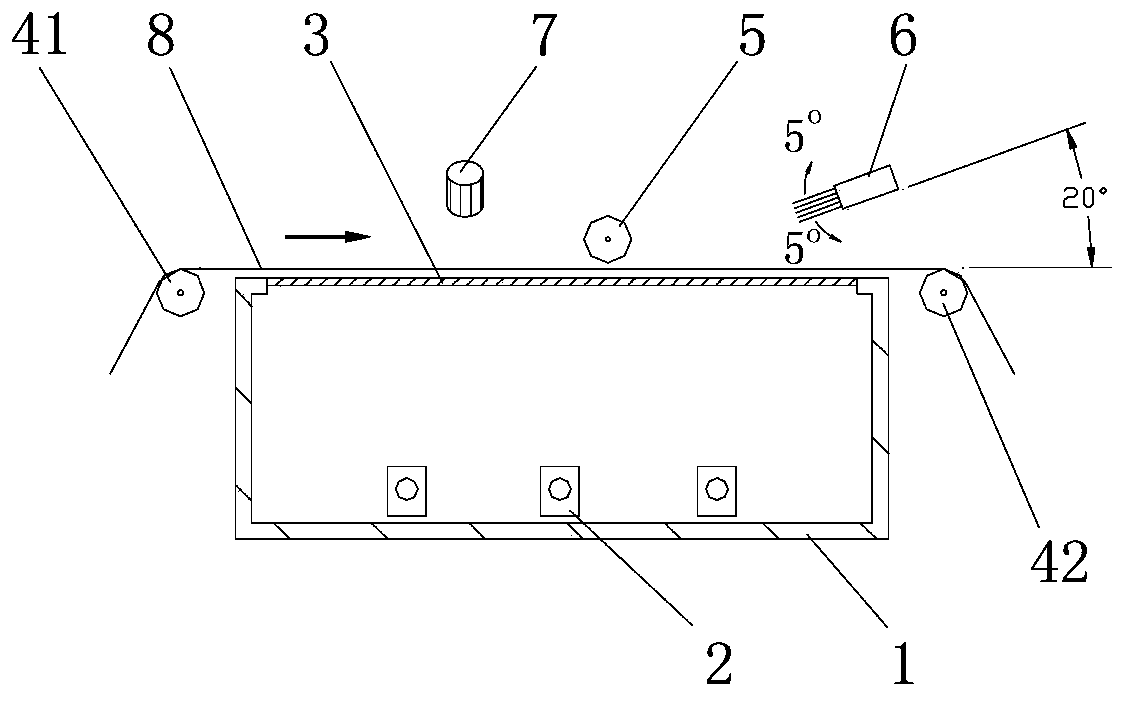

[0022] Such as figure 1 , figure 2 As shown, a paper inspection platform includes: light box 1; fluorescent lamp group 2, which is installed in the light box 1 and is composed of several fluorescent lamps and arranged uniformly; inner frosted glass 3 (the side of the glass close to the light box 1 is frosted), It is installed on the top of the light box 1; paper feed guide roller 41 and paper discharge guide roller 42, which are installed in parallel on both sides of the light box 1, are used to transport the paper 8 above the inner frosted glass 3, by setting the paper feed guide roller 41 and the paper-out guide roller 42 can prevent the paper from being pulled when it moves; the length meter 5 is installed above the inner frosted glass 3 for measuring the length of the paper 8; the front spotlight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com