Unmanned aerial vehicle inspection system and method

A technology of machine inspection line and drone, applied in the field of power transmission and distribution, to shorten the inspection time, improve inspection quality, and reduce omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained in detail below in conjunction with the accompanying drawings and preferred embodiments.

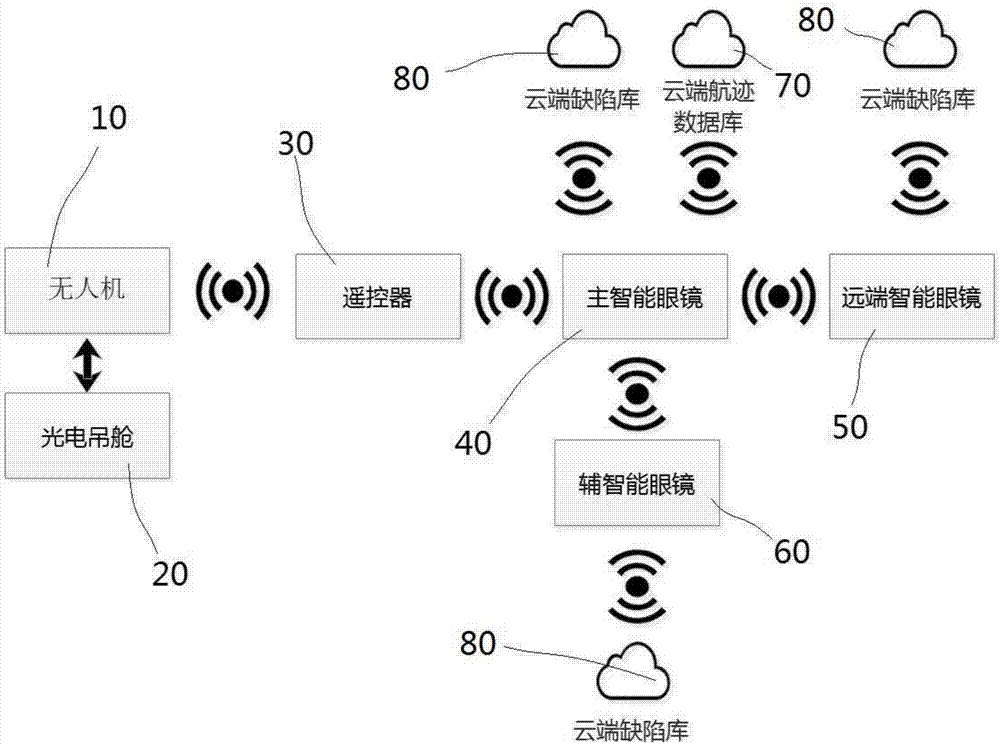

[0019] Such as figure 1 As shown, a UAV line inspection system consists of UAV 10, photoelectric pod 20, remote control 30, cloud defect library, cloud track database 70, main smart glasses 40, auxiliary smart glasses 60, remote smart Glasses 50 composition. The drone 10 mounts the photoelectric pod 20 and communicates with the remote control 30. The remote control 30 communicates with the main smart glasses 40. The main smart glasses 40 can communicate with the cloud defect library, the cloud track database 70, and the auxiliary smart glasses respectively. 60. The remote smart glasses 50 communicate, and the auxiliary smart glasses 60 and the remote smart glasses 50 can respectively communicate with the cloud defect database. The UAV 10 can automatically perform tasks according to the preset flight path, and the captured pictures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com