A Construction Method of Decoupling Controller for Bearingless Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor and decoupling controller technology, which is applied in the direction of motor generator control, electronic commutation motor control, electromechanical brake control, etc., can solve the problems of difficult extraction of ideal samples, long training time, slow learning speed, etc. Achieve the effects of excellent control system performance, high-performance operation control, and improved performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

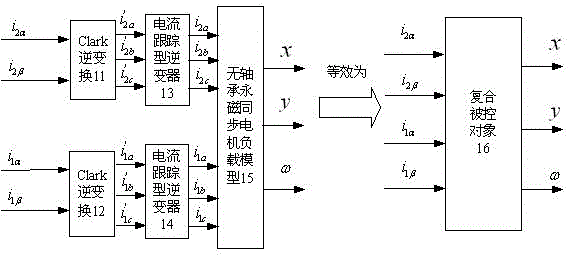

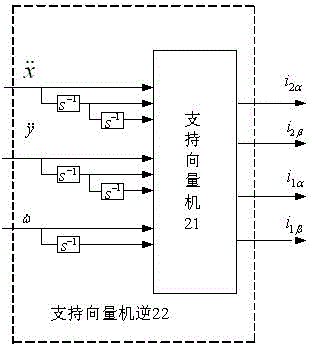

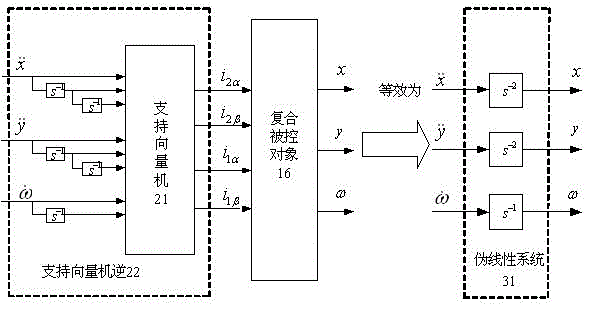

[0017] Embodiments of the present invention are as follows: first, two Clark inverse transforms, two current tracking inverters and bearingless permanent magnet synchronous motor loads are used as a whole to form a composite controlled object, which is equivalent to a 5 The order differential equation model, the relative order of the system vector is {2,2,1}. A support vector machine with 8 input nodes and 4 output nodes plus 5 integrators s -1 Form the inverse of support vector machine for compound plant with 8 input nodes and 4 output nodes. Then the support vector machine is inversely connected before the compound controlled object, and the support vector machine inverse and the compound controlled object are synthesized into two displacement second-order integral subsystems and a rotational speed first-order integral subsystem, thus a complex multivariable , nonlinear, strongly coupled control system is transformed into the control of two second-order integral subsystems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com