Water-level-variable terminal catchment inclined tube or inclined plate sedimentation tank

A technology of inclined tube sedimentation tank and variable water level, applied in the field of sedimentation tanks, can solve the problems of large water collection in the effluent weir and inability to adjust water distribution, and achieve the effects of improving the uniformity of water distribution, reducing the load of influent water, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

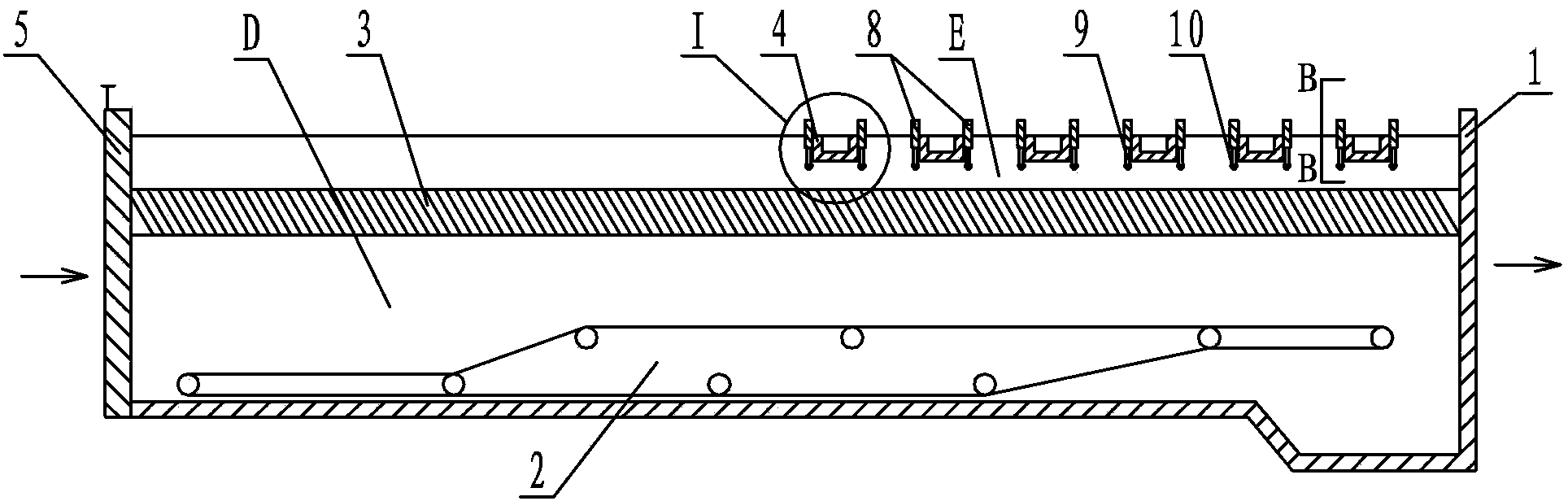

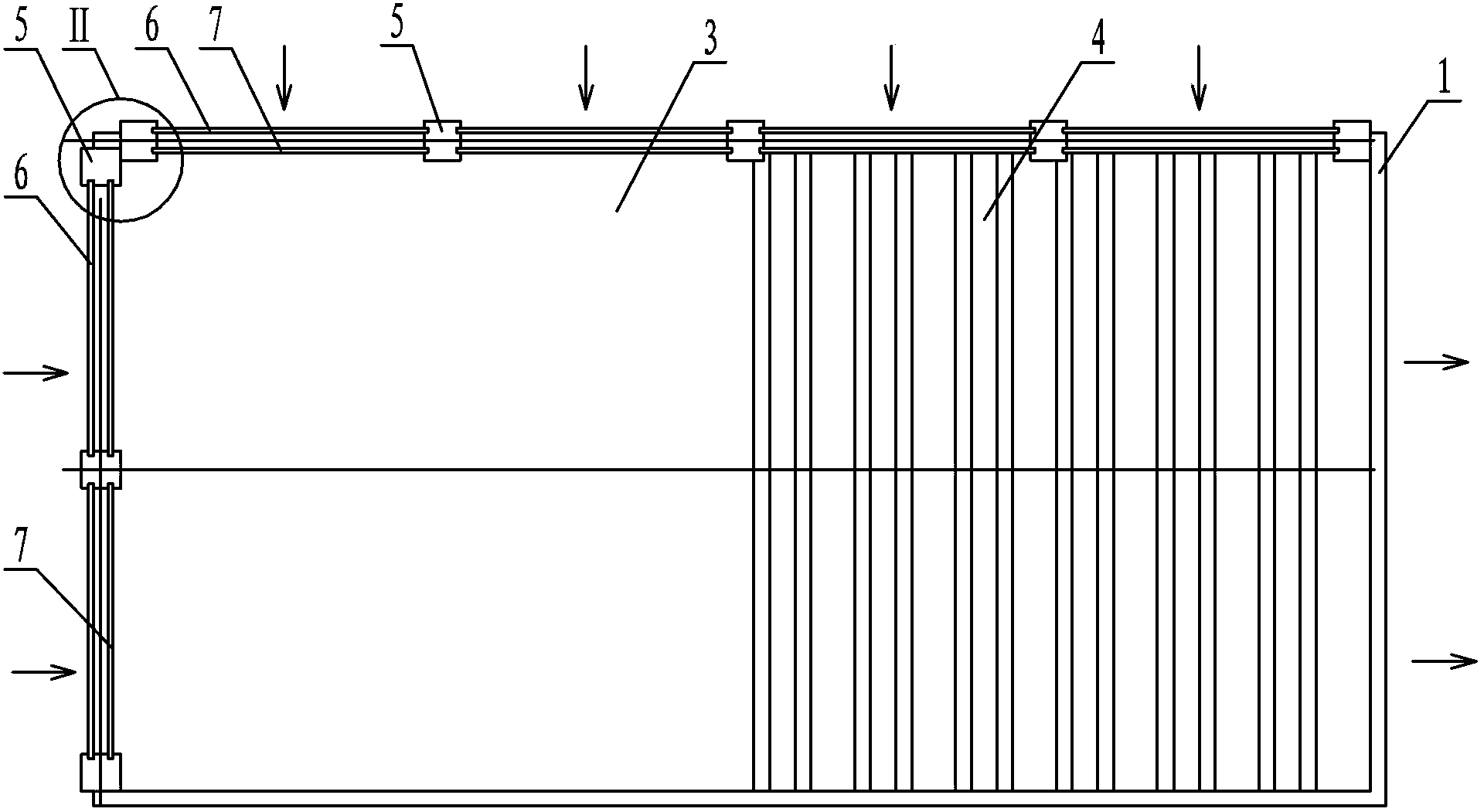

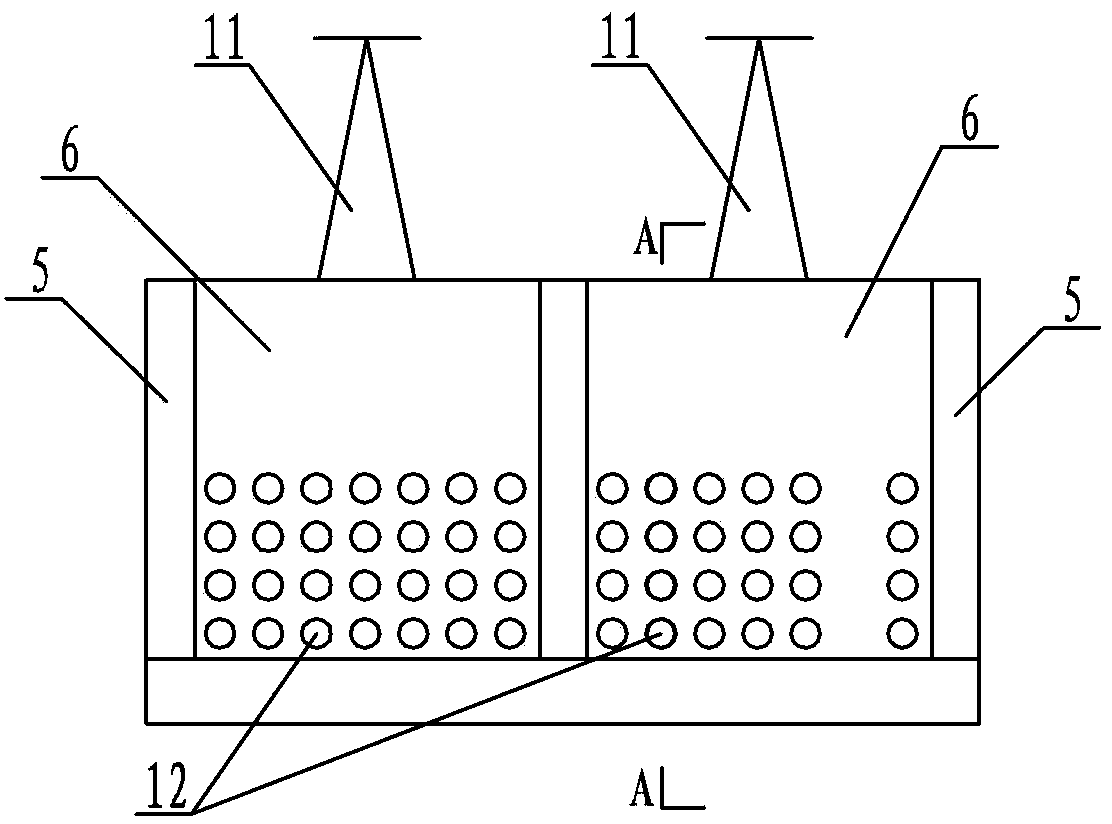

[0011] Specific implementation mode one: combine Figure 1 to Figure 7 This embodiment is described. The variable water level terminal water collection inclined tube sedimentation tank of this embodiment includes a tank body 1, a mud scraper 2, an inclined tube 3, several outlet weirs 4, several columns 5, several fixed gates 6, Several movable gates 7, several lifting plates 8, several lifting rods 9, several regulators 10, several hoists 11 and several water weir supports 13, and the mud scraper 2 is arranged at the bottom of the pool body 1 , the inclined pipe 3 is arranged in the middle of the pool body 1, and several outlet weirs 4 are arranged above the rear section of the pool body 1, and several outlet weirs 4 are evenly distributed along the longitudinal direction of the pool body 1, and the weirs of each outlet weir 4 The upper end of the wall is provided with evenly distributed internal sawtooth 4-1 along the length direction, and a water weir support 13 is fixed be...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 7 To describe this embodiment, the distance between every two adjacent elevating rods 9 in this embodiment is 2.5 meters to 3.5 meters. The distance between every two adjacent lifting rods 9 is within the above range, so that the lifting effect of the lifting plate 8 is optimal. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination image 3 To describe this embodiment, the water inlet hole 12 of this embodiment is a round hole or a square hole. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com