Resin panel earth-rock fill dam and panel construction method

A technology of earth-rock dams and panels, applied in dams, barrages, sea area projects, etc., can solve the problems of large amount of materials, difficult construction, difficult maintenance, etc., and achieve the effects of low cost, easy construction and maintenance, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

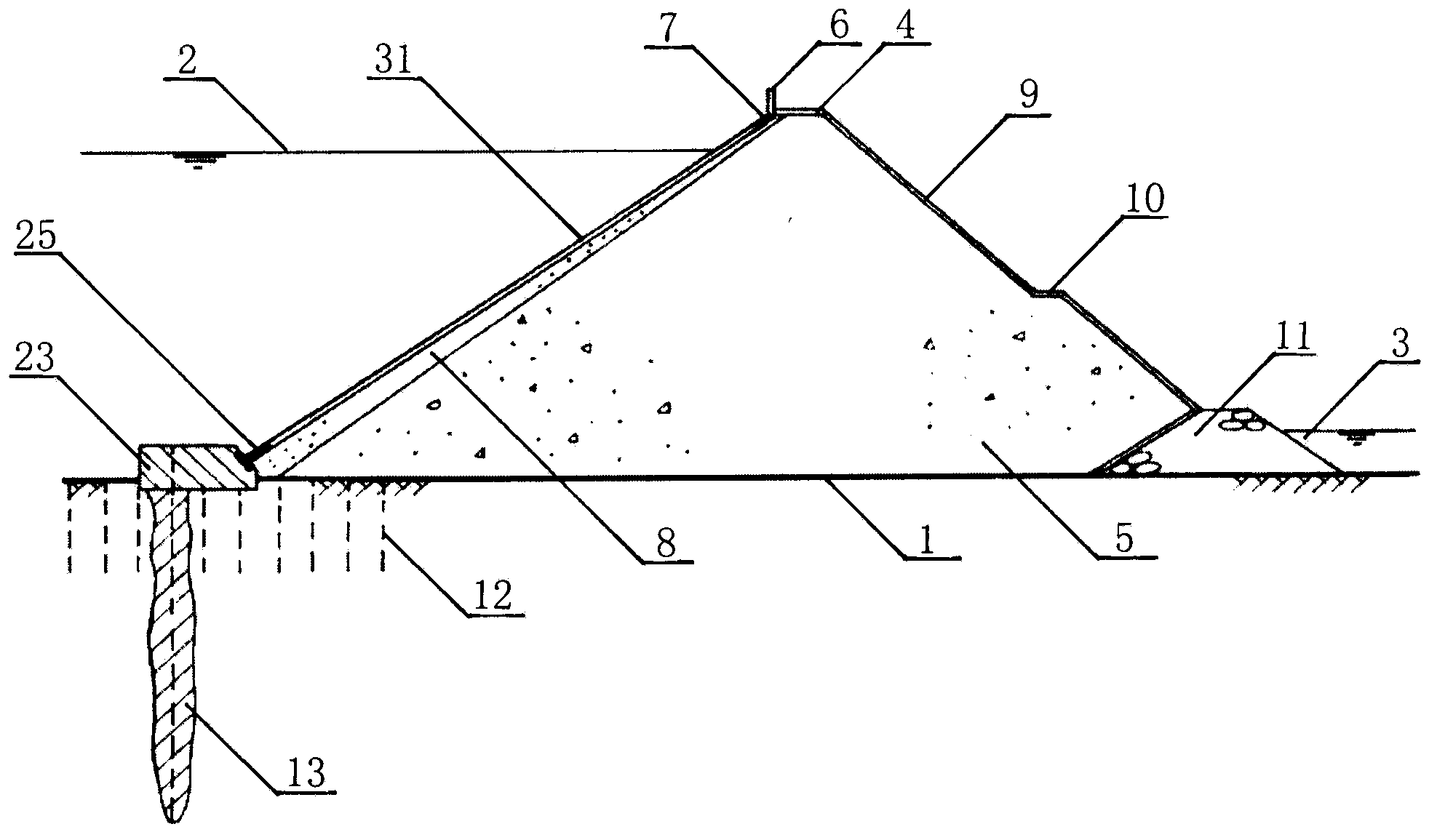

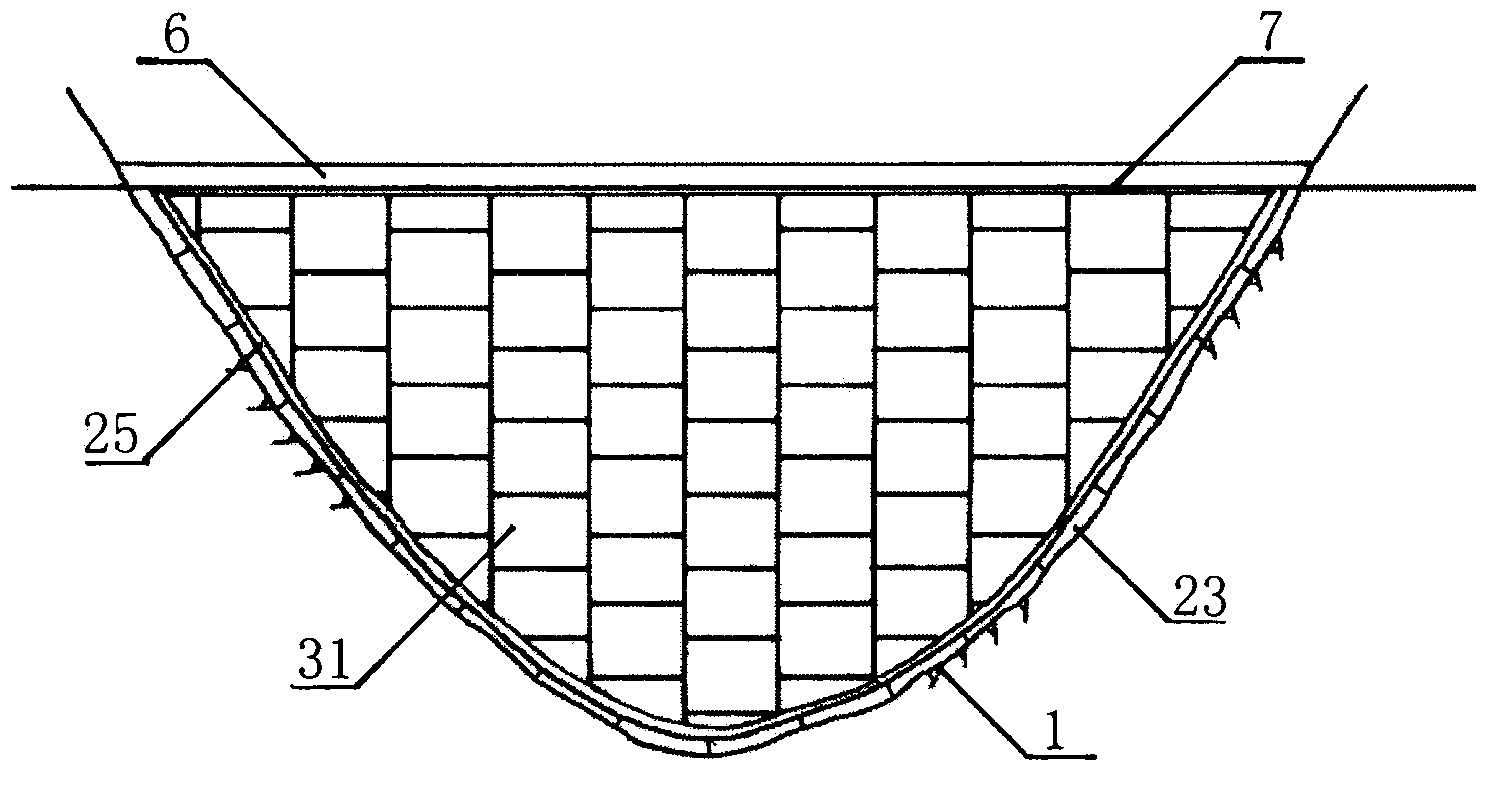

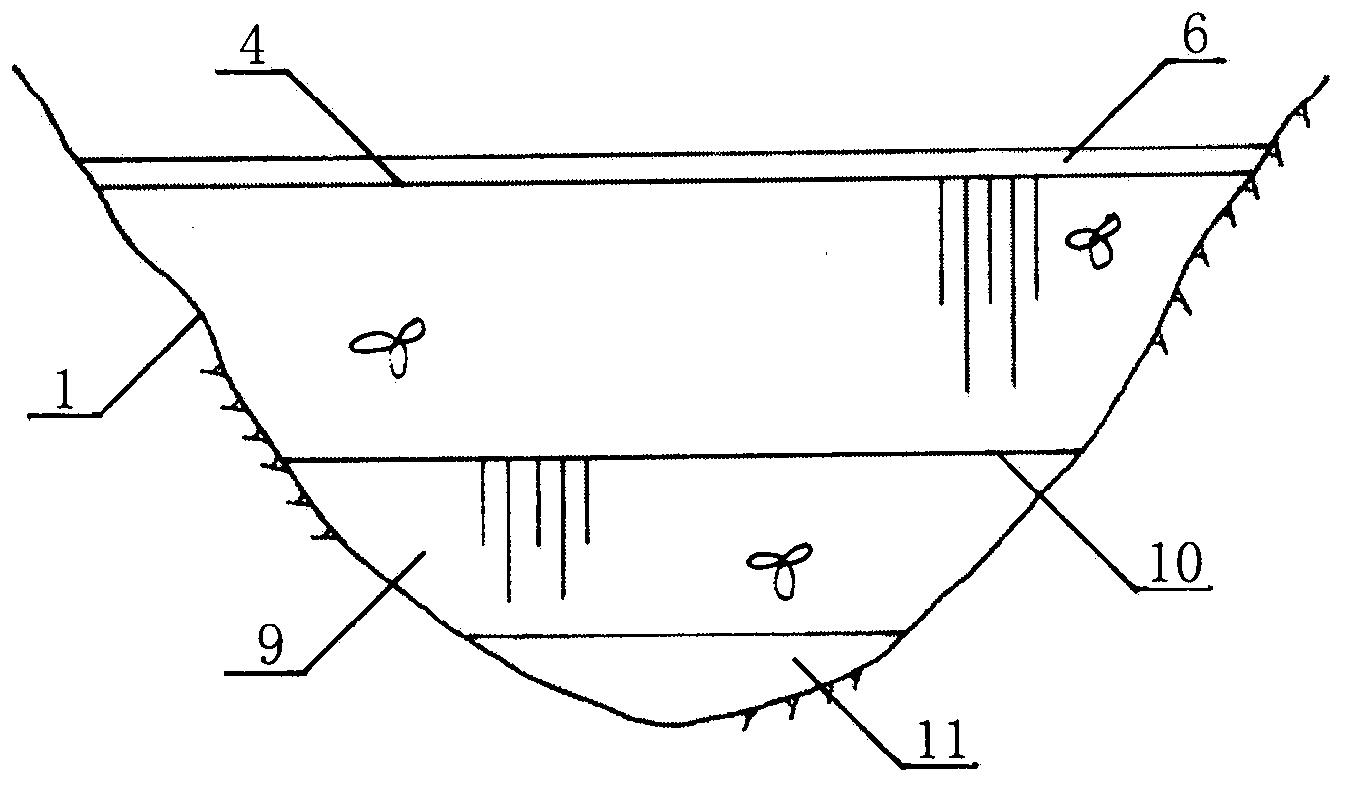

[0033] see figure 1 , figure 2 , image 3 and Figure 4 , is a kind of resin face-rock earth-rock dam of the present invention, and it is built on the resin face-rock earth-rock dam on river course or mountain stream rock foundation 1, and the cross-section of earth-rock dam body 5 of this dam is trapezoidal shape, and dam crest 4 has anti-wave wall 6, There is a toe seat 23 at the foot of the upstream slope from the river bed to the abutments on both sides. The upstream dam slope has a resin panel 31 for slope protection. There is an elastic connector 25 between the resin panel 31 and the toe seat 23. The resin panel 31 is connected to the anti-wave The walls 6 are connected by settlement connectors 7 to form a closed anti-seepage body. There is a gravel transition layer 8 narrow at the top and wide at the bottom between the backwater surface of the resin panel 31 and the earth-rock dam body 5. There is a rock revetment 9 on the slope of the downstream dam and a horseway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com