Ventilating and sound insulating secondary frame sectional material

A frame profile and ventilation frame technology, which is used in ventilation layout, sound insulation doors/windows, window/door frames, etc. The quality of installation and the impact of construction progress, etc., can avoid gaps and water seepage problems, facilitate installation and maintenance, and overcome high costs and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

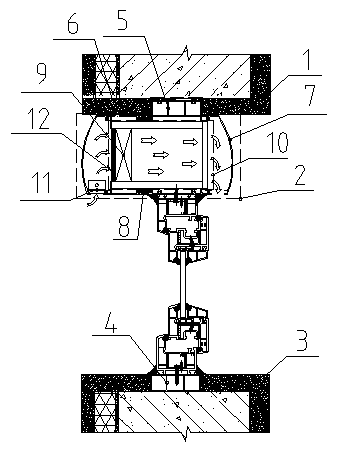

[0025] Example 1, such as figure 1 As shown, a sub-frame profile for ventilation and sound insulation includes a ventilation frame 2 partially pre-embedded in the upper wall 1 and a pre-embedded frame 4 pre-embedded in the lower wall 3, wherein the ventilation frame 2 and the pre-embedded frame 4 fixedly connected to form an opening frame; the ventilation frame 2 includes a main frame 5 pre-buried in the upper wall 1 and a sub-frame 6 fixedly connected under the main frame 5, and a buckle cover 7 is installed on the main frame 5 and the sub-frame 6 ; The main frame 5 and the sub-frame 6 are provided with a C-shaped groove, the top of the buckle cover 7 is a U-shaped groove, and the U-shaped groove is engaged with the C-shaped groove, and the bottom of the buckle cover 7 is an undercut structure. The resilient force formed by the radian of the middle part of 7 clamps the buckle cover 7 on the main frame 5 and the sub-frame 6; the buckle cover 7 is a double-layer structure, and ...

Embodiment 2

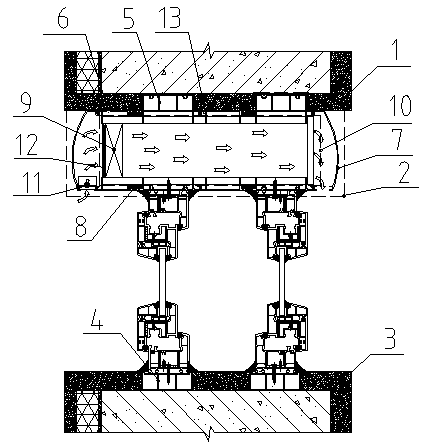

[0026] Embodiment 2: as figure 2 As shown, the difference from Embodiment 1 is that this case adopts a double-layer structure, that is, on the basis of Embodiment 1, the opening frames are arranged side by side, and the two are connected by a connecting frame 13 to form a double-layer sub-frame type. The flow direction of fresh air like figure 2 indicated by the arrow in .

[0027] Whether it is embodiment 1 or embodiment 2, when installing, the main frame 5, sub-frame 6, buckle cover 7 and damping heat insulation strip 8 are combined into a ventilation frame 2, and then ventilation holes are milled inside it to install the power frame. The fan 9 and the sound-absorbing material are then combined with the pre-embedded frame 4 to form an opening frame. Before the civil engineering plastering or wet work is completed, the opening frame is installed in the wall. After the civil engineering plastering and wet work are completed, Only part of the ventilation frame 2 is exposed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com