Rotary type tubing drain and use method thereof

A technology of oil drainer and rotary type, which is applied in the field of oil drainer, can solve the problems of complex unlocking structure of the oil drainer, and achieve the effects of wide application range, convenient use, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

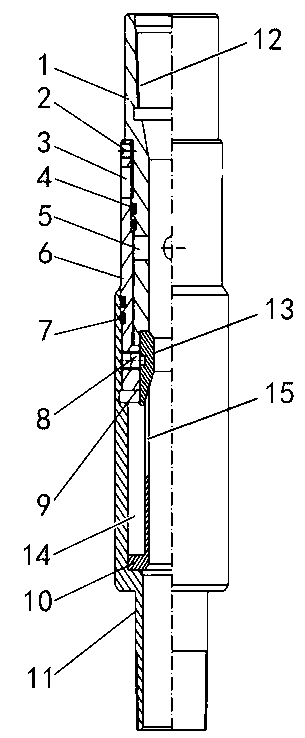

[0021] The specific embodiment of the rotary oil pipe drainer of the present invention is as figure 1 As shown, the oil pipe oil drainer includes an oil drain pipe 1, an oil drain sleeve 6 and a lower joint 11 arranged sequentially from top to bottom. An external thread is provided on the surface, and an internal thread is correspondingly provided in the oil drain sleeve 6, and the oil drain pipe 1 is inserted into the oil drain sleeve 6 to be threadedly connected thereto. Oil drain holes are opened on the side walls of the oil drain pipe 1 and the oil drain sleeve 6 respectively, wherein the inner oil drain hole 5 on the oil drain pipe 1 is lower than the outer oil drain hole 3 on the oil drain sleeve 6 when assembled, and Between the inner oil drain hole 5 and the outer oil drain hole 3, there are two sealing rings 4 on the outer wall of the oil drain pipe 1 for sealing the gap between the oil drain pipe 1 and the oil drain sleeve 6. The inner oil drain hole 5 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com