Method and apparatus for producing a mat of spread material and a mat of spread material

A technology for equipment and material flow, applied in applications, household appliances, household components, etc., which can solve problems such as difficult to clean, easy to block, and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

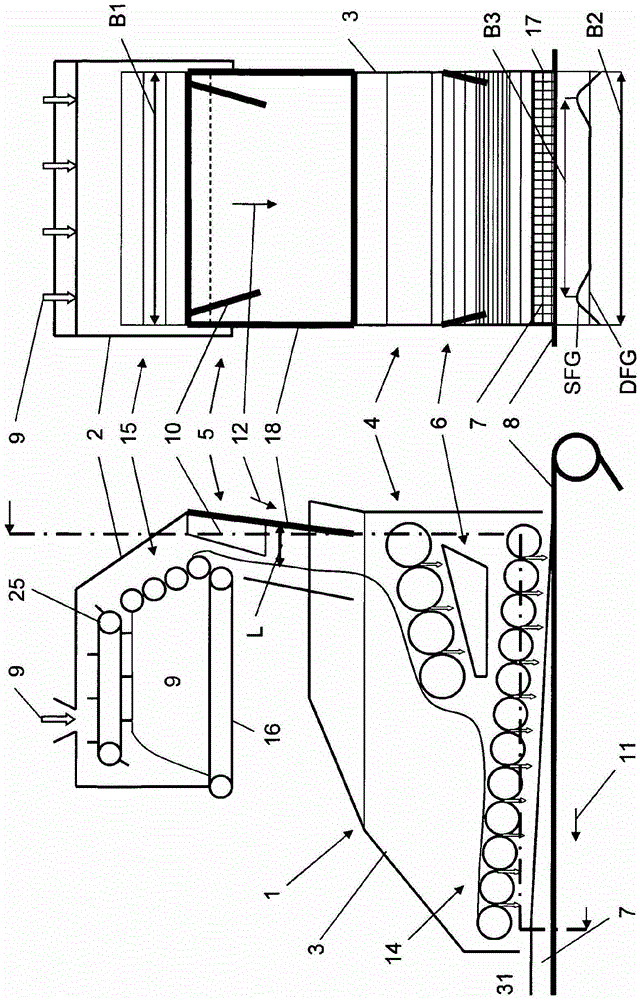

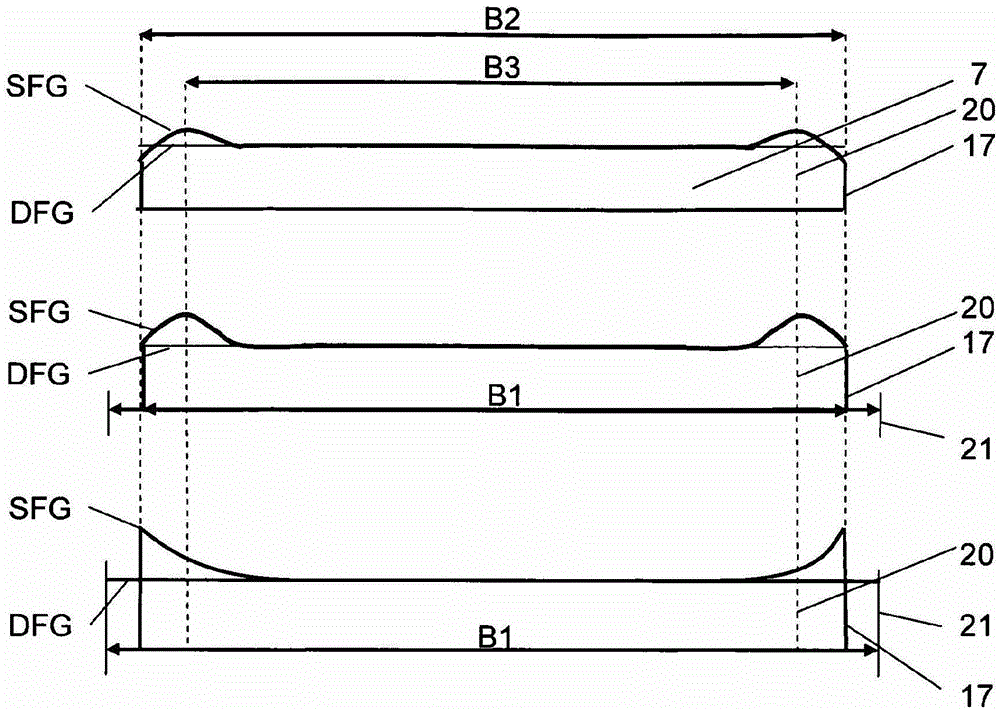

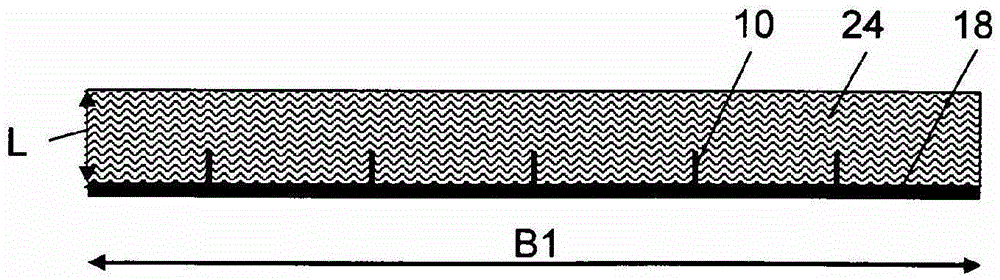

[0046] exist figure 1 On the left in the middle is a schematic illustration of an example device for producing a mat 7 of spreading material for pressing in a press 22 . See on the right a side view of the section line according to the left image. In this device, the spreading material 9 is fed into the silo 2 and is fed in a controlled manner to the dosing device 15 by means of a scraper 25 and an endlessly revolving silo bottom belt 16 located beneath it. The dosing device 15 discharges the spread material with a uniform dosing weight per unit area DFG (shown below right) along the width B1. Along the direction of motion 12 that generally corresponds to the direction of fall of the spreading material 9, thereby constituting a width B1 substantially moving in the direction of the spreading head 1, having a width B1 transverse to the production direction 11 (corresponding to the direction of movement of the forming belt 8) and along the A material flow 24 of length L in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com